Overhauling position lance adjusting device for converter oxygen lance

A steel-making converter and limit structure technology, applied in the direction of manufacturing converters, etc., can solve the problems of wasting production time, manpower and material resources, etc., and achieve the effects of long service cycle, reduced errors, and shortened gun adjustment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

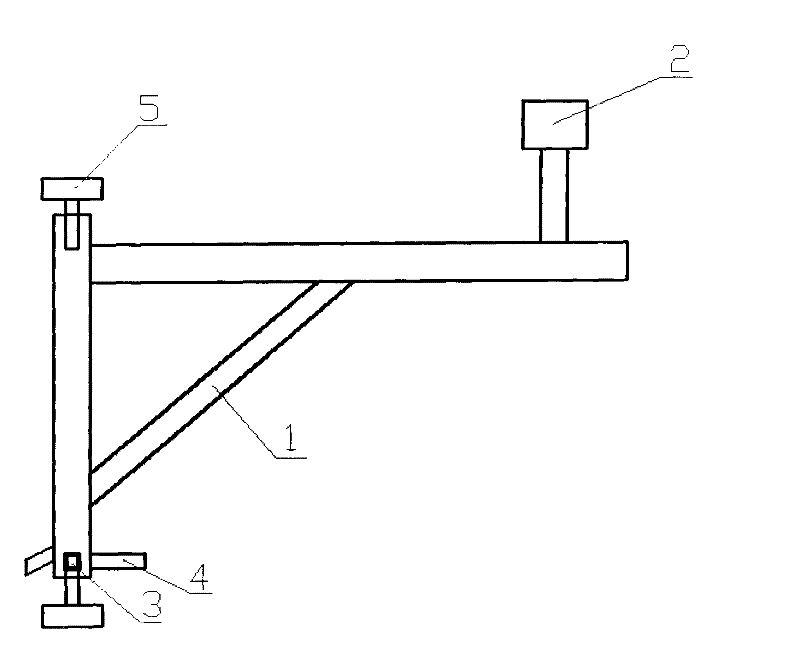

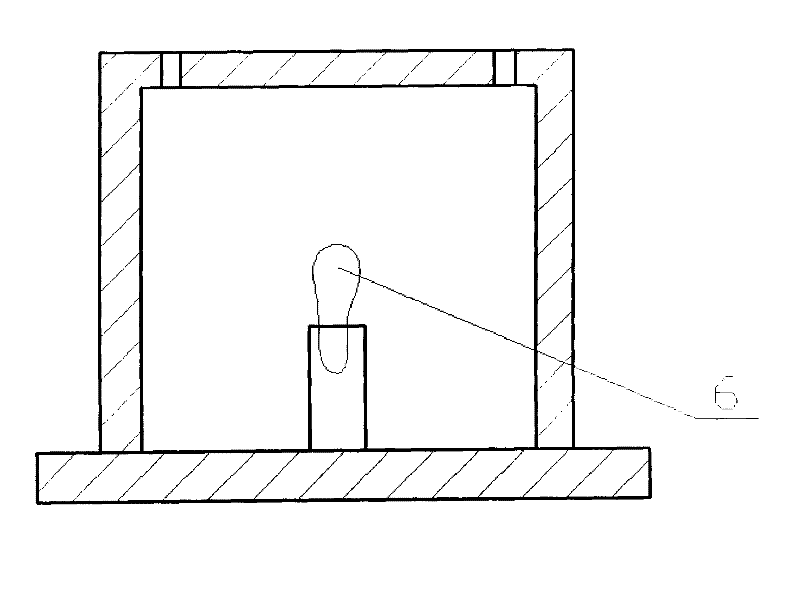

[0011] In the figure, the gun adjustment device 1 is in the standby position when not in use. When in use, the entire device 1 is rotated to the working position, and the position is fixed with the limit position 3 in the figure, and the limit bolt is screwed into the nut to ensure its accuracy. Then turn on the light 6, and the operator watches the light on the calibration head on the oxygen lance lifting trolley to adjust the oxygen lance. After the adjustment, turn off the light 6, rotate the gun adjustment device to the standby position, and fix it with the limit position 4 It is enough to meet the normal production needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com