Refining method for biodiesel coarse product

A technology of biodiesel and refining method, which is applied in the field of refining biodiesel crude products, and can solve the problem that the removal of light components cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] According to the present invention, the source of the crude biodiesel product is not particularly limited, and is generally prepared. The preparation method of the crude product of biodiesel can be the preparation method of various existing biodiesel, and the method of described preparation can usually be under the condition of transesterification reaction, the raw material grease and the low-carbon alcohol of C1-C4 contact reaction Obtain biodiesel crude product. Wherein, the transesterification reaction conditions may be conventional transesterification reaction conditions for preparing biodiesel in the art. For example, the transesterification reaction conditions include: a pressure of 6-8.5 MPa (gauge pressure) and a temperature of 240-280° C.; preferably, a pressure of 6-7 MPa (gauge pressure) and a temperature of 250-260° C. No need for catalyst intervention, the ratio of alcohol to oil is 9-12:1 (molar ratio). For example, the raw oil can be selected from one o...

Embodiment 1

[0043] This embodiment is used to illustrate the refining method of the biodiesel crude product provided by the present invention.

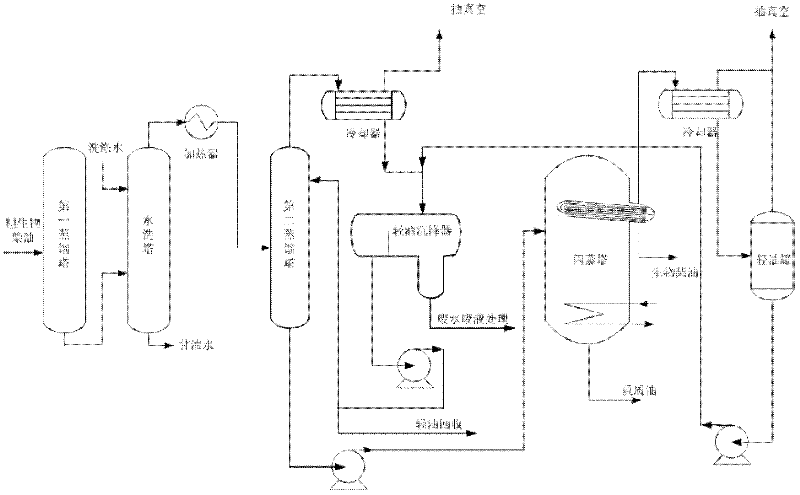

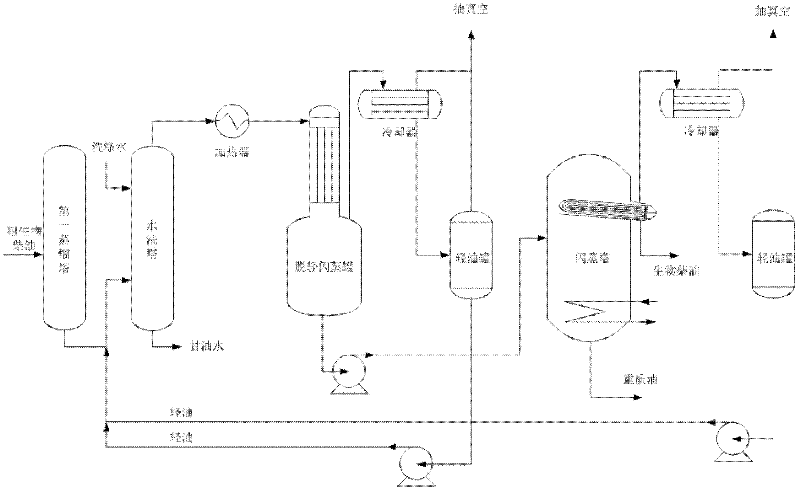

[0044] (1) if figure 1 As shown, the biodiesel crude product is sent to the first distillation tower for methanol distillation. The conditions of methanol distillation include: the tower top pressure is 20KPa, the tower top temperature is 64°C, the bottom temperature is 86°C, and methanol is extracted from the top of the tower , from the bottom of the tower to remove most of the biodiesel crude product of methanol;

[0045] (2) send the crude biodiesel product after methanol distillation obtained at the bottom of the first distillation tower into a water washing tower for washing, and wash the crude biodiesel product with water. The washing conditions include: the amount of washing water and the crude product of biodiesel The weight ratio of the amount is 0.2:1, the washing temperature is 85°C, and the time is 1.5 hours;

[0046] (3) After the...

Embodiment 2

[0053] This embodiment is used to illustrate the refining method of the biodiesel crude product provided by the present invention.

[0054] (1) if figure 1 As shown, the biodiesel crude product is sent to the first distillation tower for methanol distillation. The conditions of methanol distillation include: the tower top pressure is 20KPa, the tower top temperature is 60°C, the bottom temperature is 80°C, and methanol is extracted from the top of the tower , from the bottom of the tower to remove most of the biodiesel crude product of methanol;

[0055] (2) send the biodiesel crude product after the methanol distillation that obtains at the bottom of the first distillation tower into the water washing tower for washing, and rinse the biodiesel crude product with water. The washing conditions include: the amount of washing water and the biodiesel crude product The weight ratio of the amount is 0.1:1, the washing temperature is 80°C, and the time is 1 hour;

[0056](3) The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com