Apparatus for manufacturing vitreous silica crucible

A glass crucible and manufacturing device technology, applied in the field of vitreous silica crucible manufacturing device, to achieve the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] An embodiment of the vitreous silica crucible manufacturing device of the present invention will be described in detail below with reference to the accompanying drawings.

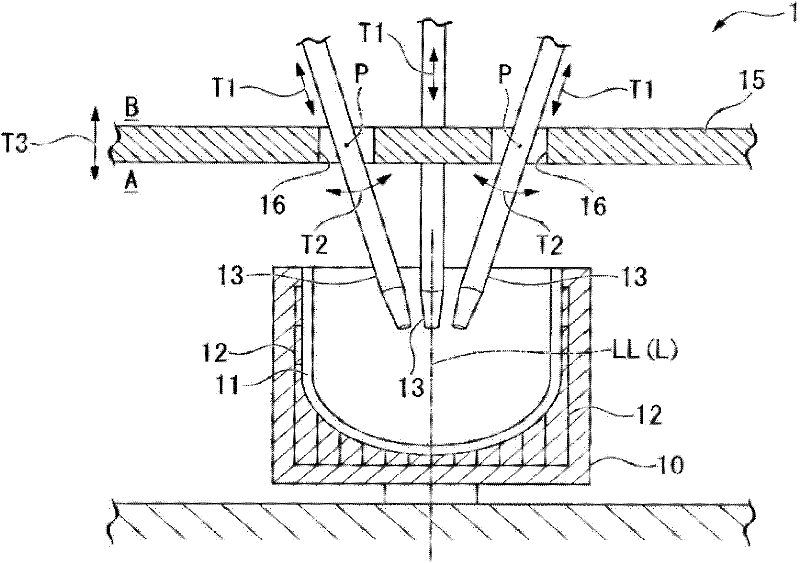

[0055] figure 1 It is a partial schematic diagram of a vitreous silica crucible manufacturing apparatus according to this embodiment, and in the figure, reference numeral 1 is a vitreous silica crucible manufacturing apparatus.

[0056] The vitreous silica crucible manufacturing apparatus 1 of the present embodiment is described as an example of a heat source for manufacturing a vitreous silica crucible with a diameter of 24 inches or more and about 32 to 44 to 50 inches. The device of the conductor is not limited to the type of material to be melted, the diameter of the crucible, the output capacity of the device, and the use as a heat source, and is not limited to the structure.

[0057] The vitreous silica crucible manufacturing apparatus 1 of the present embodiment is divided into a melting cham...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com