Simple preparation method for high-purity houghite compound with adjustable interlayer spacing

A technology for hydrotalcites and compounds is applied in the field of preparation of hydrotalcite compounds, which can solve the problems of affecting product purity, lack of clear understanding of product washing methods and conditions, and lack of defined technical routes for hydrotalcites, and achieves simple operation and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

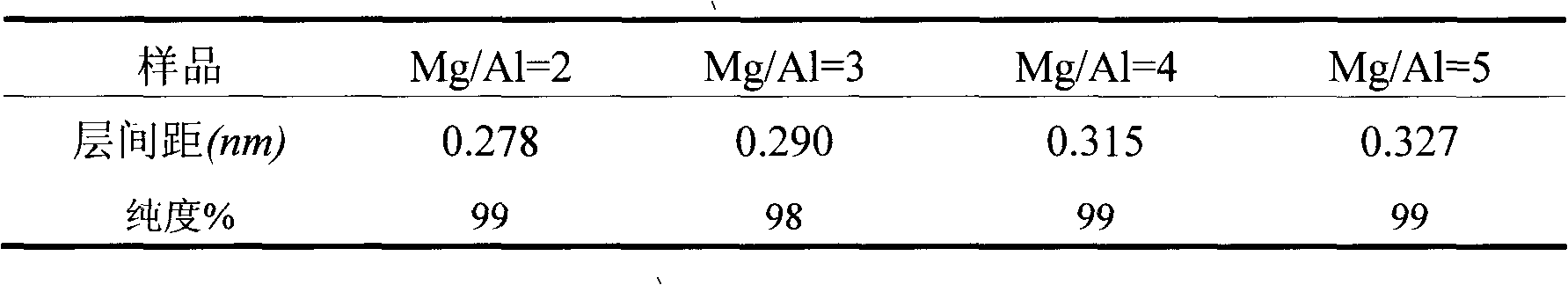

[0016] Weigh 0.24mol of MgCl 2 ·6H 2 O and 0.24 / k mol of AlCl 3 9H 2 O to make 200mL salt solution (k is the ratio of magnesium to aluminum, take 2, 3, 4, 5), weigh 0.24×(2+2 / k) mol NaOH and 0.12 / k mol NaOH 2 CO 3 Dubbed 200mL of alkali solution. The salt solution and the alkali solution were dropped into 100 mL of deionized water at a controlled rate (90 drops / min) at the same time, and stirred at a medium speed with a magnetic stirrer to maintain the pH of the system at 10 and the constant temperature at 40°C. After the dropwise addition, fully stir for 20 minutes, place the resulting precipitate in a constant temperature water bath, crystallize at a constant temperature of 65°C for 18 hours, and use a conductivity of 2μs.cm -1 Centrifuge and wash the precipitate with deionized water at a centrifugal speed of 8000 rpm, and wash repeatedly until the conductivity value of the supernatant is 150 μs.cm -1 , and then the precipitate was dried at 100°C for 8h.

[0017] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com