A fully automatic carrot cleaning and grading packaging device

A cleaning device, carrot technology, applied in packaging, packaged food, packaging protection and other directions, can solve the problems of increased manpower, low production efficiency, and increased production costs in detection and grading, saving labor labor, strong grading objectivity, and improved grading. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

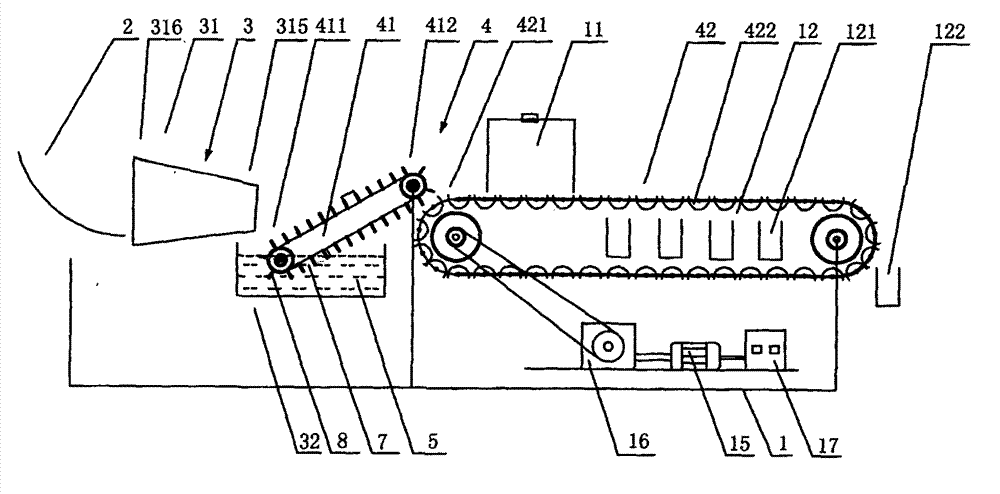

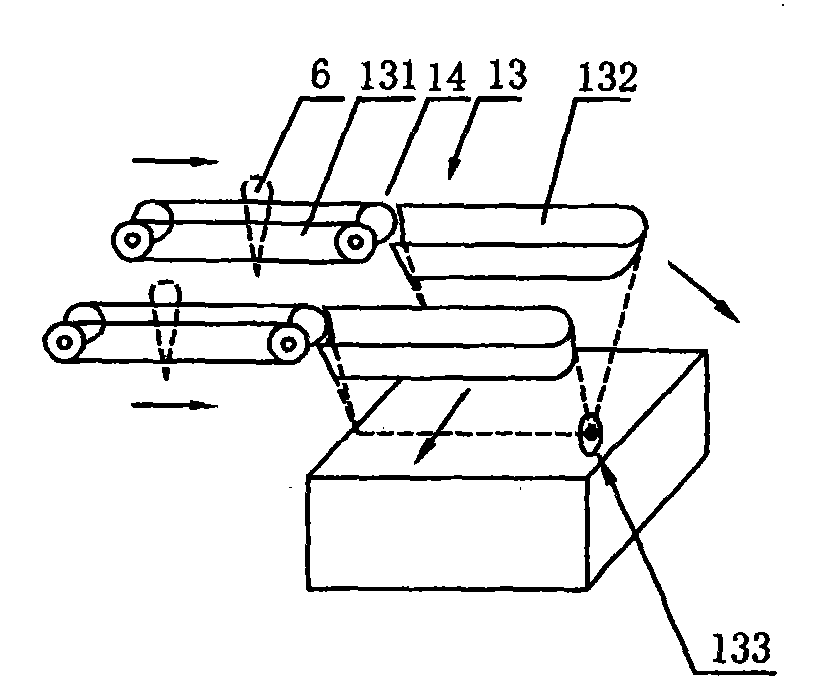

[0020] The invention can be used for washing, grading and boxing carrots. It consists of cleaning part, grading part and packing part.

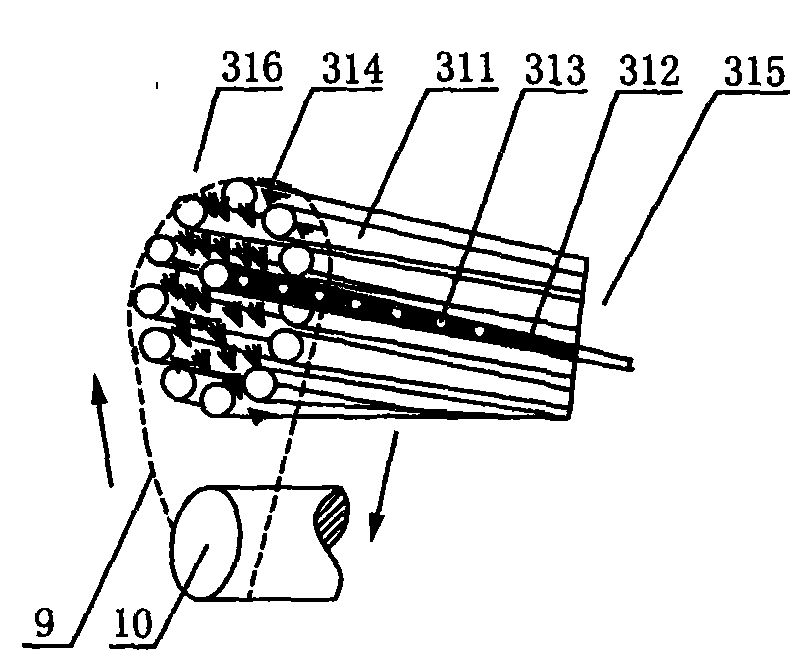

[0021] like figure 1 , 2 , shown in 3, a kind of full-automatic carrot cleaning and grading packing device, comprises frame 1, feed inlet 2 is set at the front end of frame 1, and the rear end of feed inlet 2 is provided with cleaning device 3, and cleaning device 3 consists of one stage The cleaning device 31 and the secondary cleaning device 32 are composed of the primary cleaning device 31 comprising a conical rotating cleaning cylinder 311 and a water spray pipe 312 arranged at the center of the conical rotating cleaning cylinder 311 and having water spray holes 313 evenly arranged on the pipe wall A brush 314 is arranged on the inner wall of the conical rotating cleaning cylinder 311, which is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com