Back-dismantling conveying system of scrapped car dismantling line

A technology for conveying systems and scrapped vehicles, which is applied in the recycling of scrapped vehicles, the removal of solid waste, motor vehicles, etc. It can solve the problems of low automation, low dismantling efficiency, cumbersome operation steps, etc., and achieve high automation and car body Stable storage and improved dismantling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

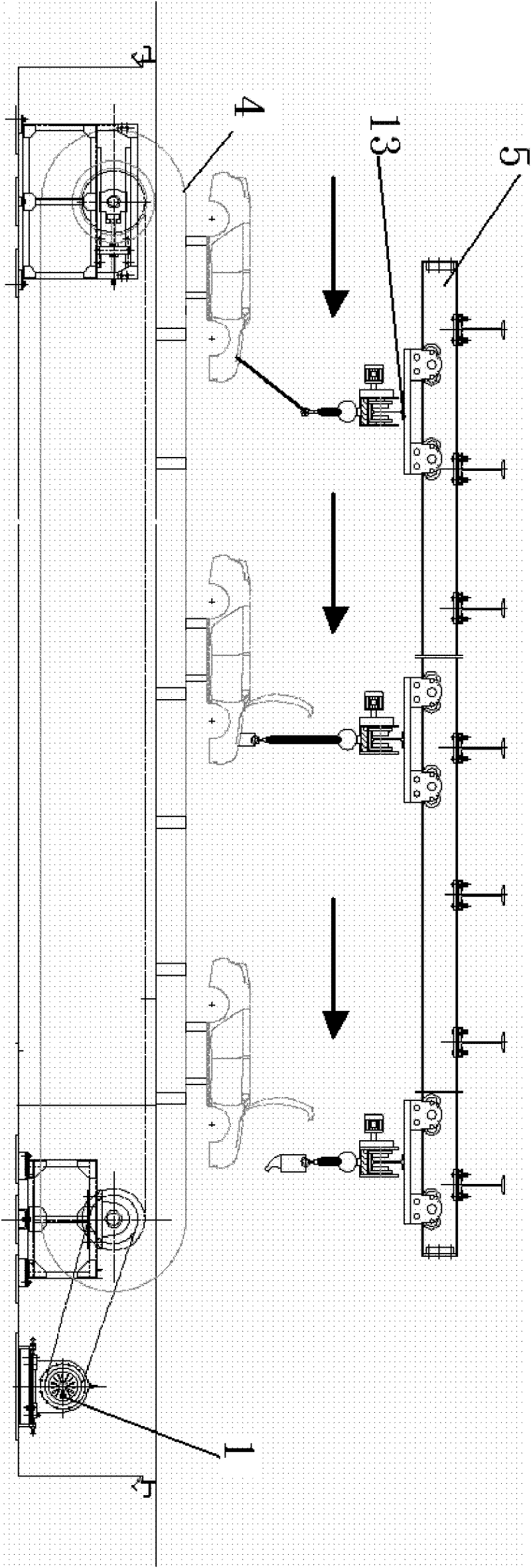

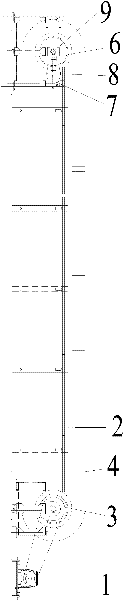

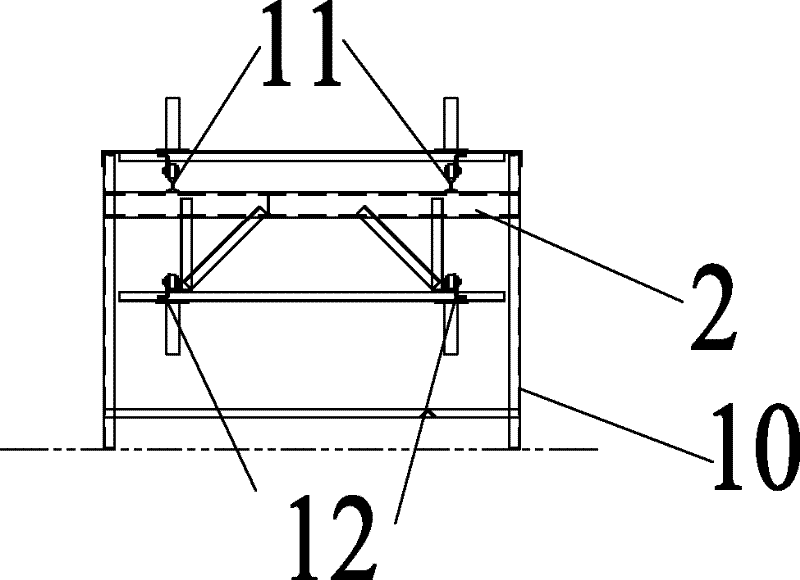

[0021] Such as figure 1 As shown, the present invention is a rear dismantling conveying system of a scrapped automobile dismantling line, which is used to dismantle the engine from above the scrapped automobile. The rear dismantled conveying system includes a support chassis, a conveying plate chain installed on the support chassis, and The driving mechanism connected to the conveying plate chain, the grasping component and the PLC module of the grasping engine located above the conveying plate chain, the driving component and the grasping component are connected with the PLC module, and the grasping component includes the circulation slide rail 5, the circulation slide rail 5 The electric hoist 13 sliding up and the spreader connected on the electric hoist 13 are also provided with a car body packing system connected with the PLC module at one end of the conveying plate chain. This rear dismantling conveying system undertakes the dismantling of the scrapped cars transported f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com