Horizontal combined machine tool with lifting spindle

A technology of combining machine tools and spindles, applied in the field of machinery, can solve problems such as large occupied space and complex machine tool structure, and achieve the effects of large feed force, stable feed and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

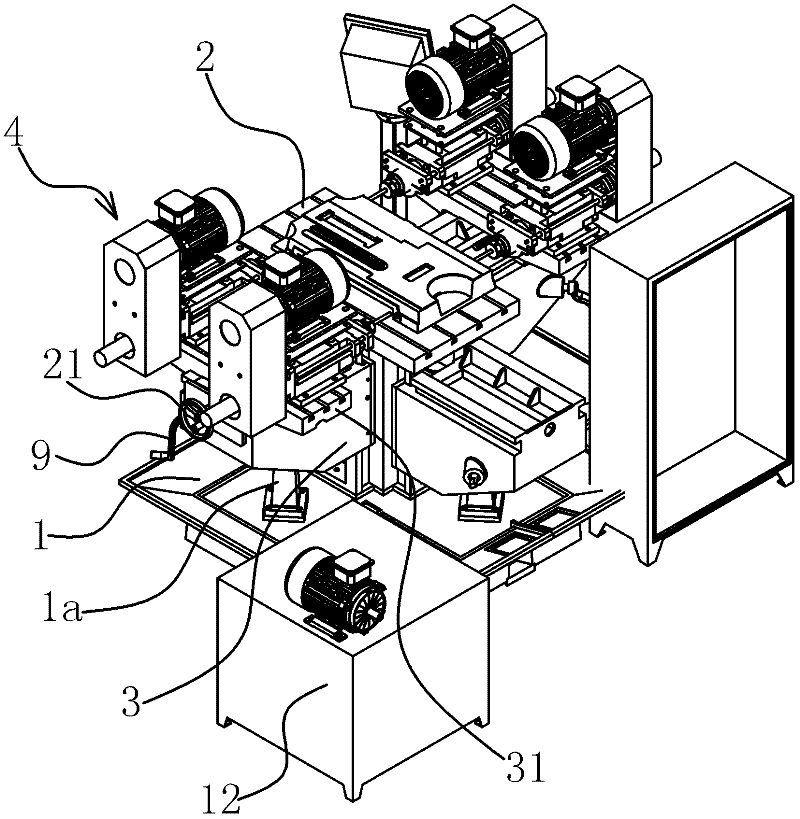

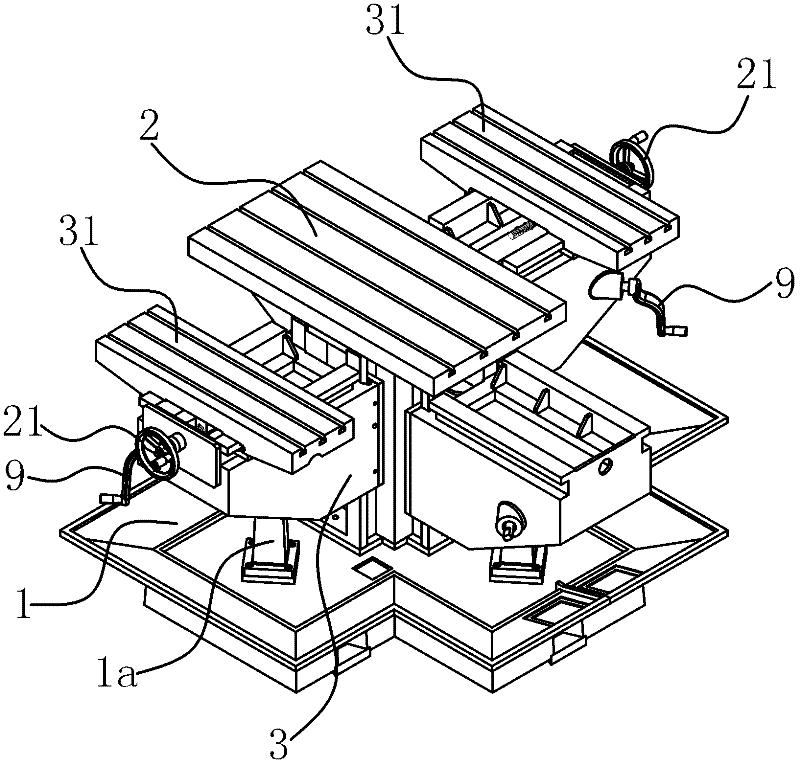

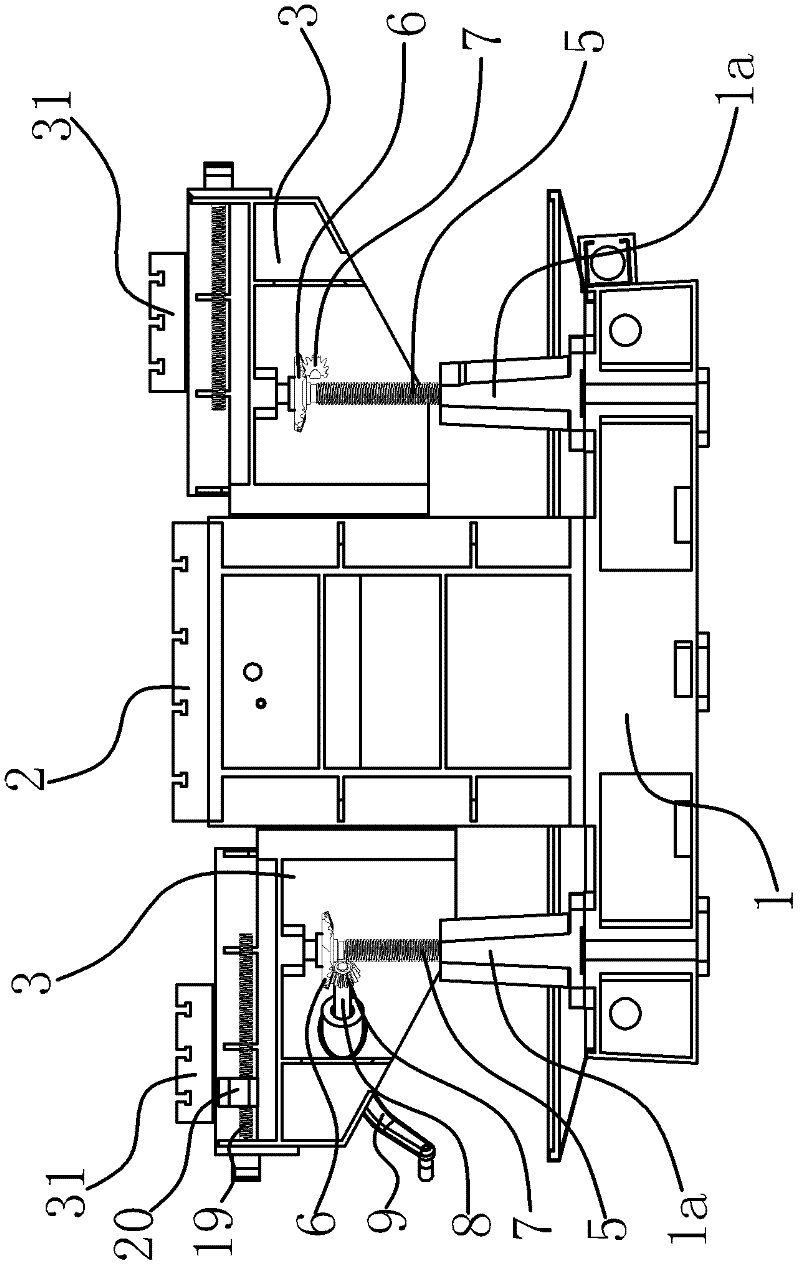

[0032] The vertical and horizontal positions of the spindle box 4 relative to the workpiece can be adjusted according to the processing requirements of the spindle lifting horizontal combined machine tool, and can process the processing requirements of holes in different positions on multiple sides of the workpiece. The spindle lifting horizontal combined machine tool includes a bed 1, a worktable 2, a spindle lifting platform 3, a spindle plate 31, a spindle box 4, a screw 5, a connecting bracket 1a, an adjustment mechanism, a feed mechanism and a drive mechanism.

[0033] Specifically, as figure 1 with figure 2 As shown, the workbench 2 is fixedly connected to the bed 1, and the two spindle lifting platforms 3 are respectively located on both sides of the workbench 2, and each workbench 2 is fixedly connected with two spindle boxes 4. Such as image 3 As shown, the bed 1 is fixedly connected with a connecting bracket 1a by bolts, and a threaded hole is processed on the co...

Embodiment 2

[0040] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the adjustment mechanism includes a bevel gear 6, a bevel gear 2 7 and an adjustment motor, and the bevel gear 1 6 is fixedly connected On the screw 5, the bevel gear 2 7 is meshed with the bevel gear 1 6, the adjusting motor is fixedly connected on the bed 1, the rotating shaft of the adjusting motor is fixedly connected with the bevel gear 2 7, and the bed 1 is also provided with a Motor control buttons. The operator can adjust the height of the main shaft elevating table 3 by pressing the control button, which is convenient to operate.

Embodiment 3

[0042] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1 or Embodiment 2, the difference is that in this embodiment, the feeding mechanism includes solenoid valve 2, hydraulic station 12 and hydraulic slide table, hydraulic slide The stage is arranged between the spindle box 4 and the spindle plate 31, and the oil inlet and the oil outlet of the hydraulic slide are connected to the hydraulic station 12 through the solenoid valve 2 respectively. The stroke of the hydraulic slide table is longer, and the purchase of the hydraulic slide table is convenient and the cost is relatively low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com