High-precision and large-diameter flange steel pipe segmenting and track-change installation device and method

An installation device and large-diameter technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as the inability to ensure the installation accuracy of steel pipes, the inability to hoist steel pipes in place at one time, and the inability to ensure one-to-one correspondence between flange eyes, etc. To achieve the effect of ensuring a smooth installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

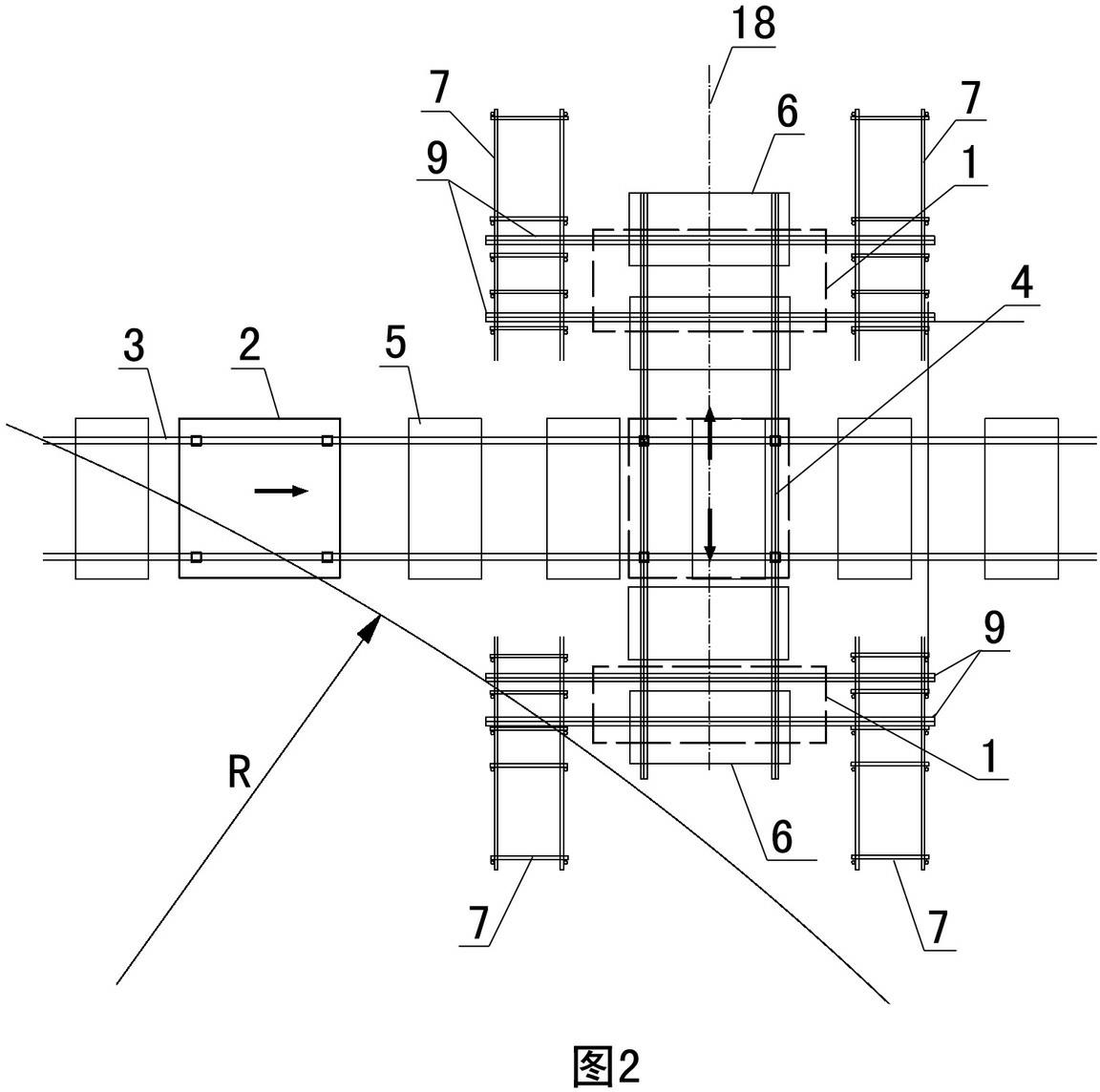

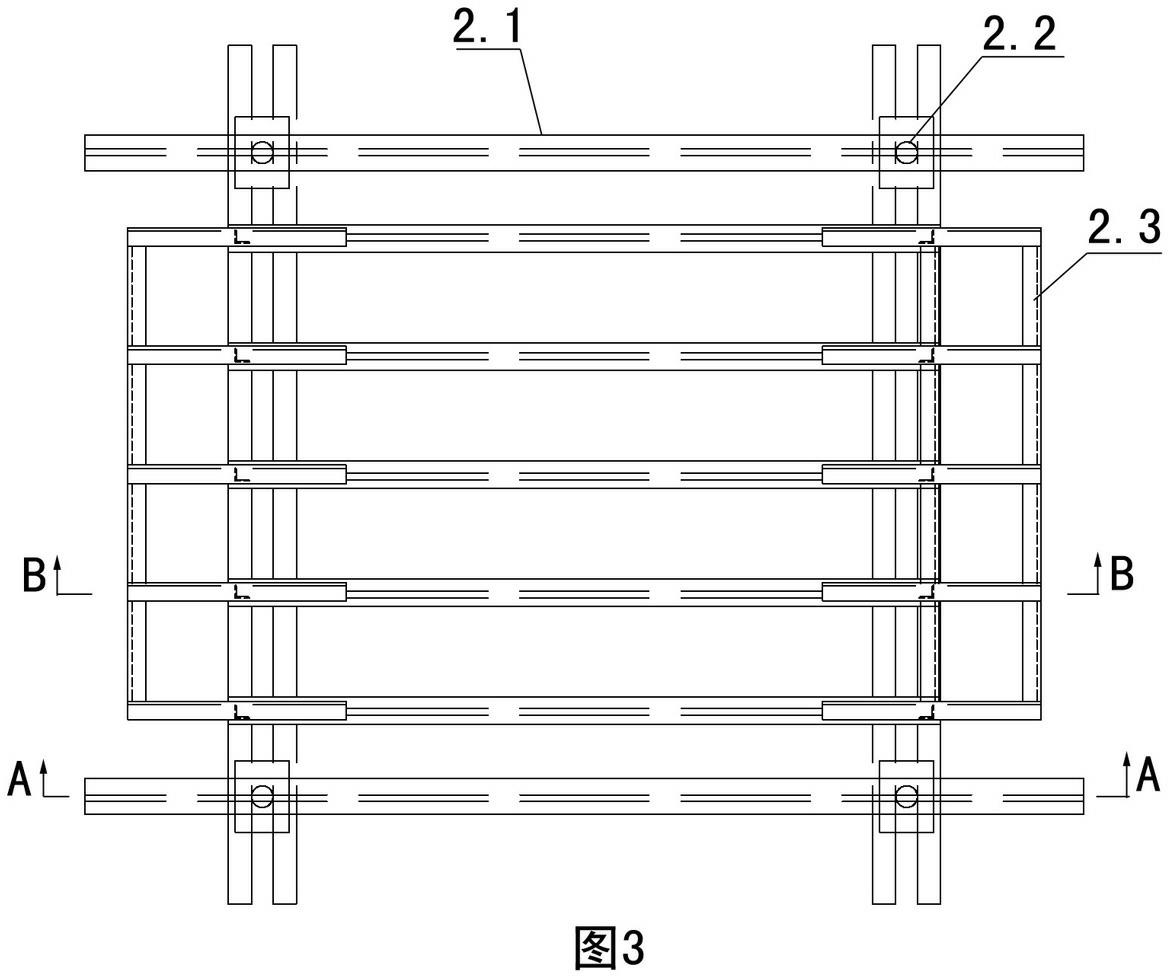

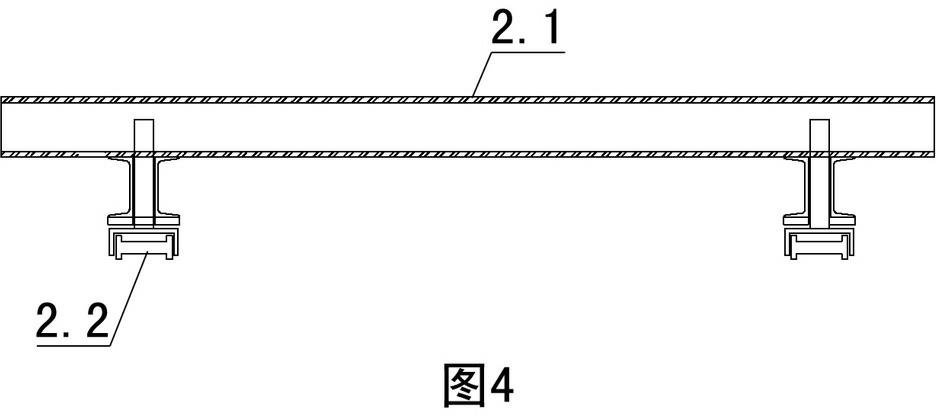

[0042] Examples see figure 2 As shown, this high-precision, large-diameter flanged steel pipe section and rail-changing installation device include a bracket, a trolley track placed on the bracket, and a transport trolley 2 with universal wheels 2.2 on the trolley track. , and the hoisting beam system set at the proposed installation position of the two steel pipes. The support is used for the support of the trolley track, the trolley track is a special channel for steel pipe transportation, the transport trolley 2 is a tool for steel pipe transportation, and the hoisting beam system is used for lifting when the steel pipe is positioned. The present invention uses two mutually perpendicular steel rails (No. 1 rail 3 and No. 2 rail 4) to transport the steel pipe 1 to an installation location outside the working range R covered by the tower crane, that is, the intended installation location of the steel pipe.

[0043] Described trolley track is made up of No. 1 track 3 and No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com