Online forecasting method for internal crack defect of casting blank

A slab and defect technology, which is applied in the field of online prediction/control of internal quality defects of slab, can solve problems such as internal cracking of slab, always existing slab, and difficult strain detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

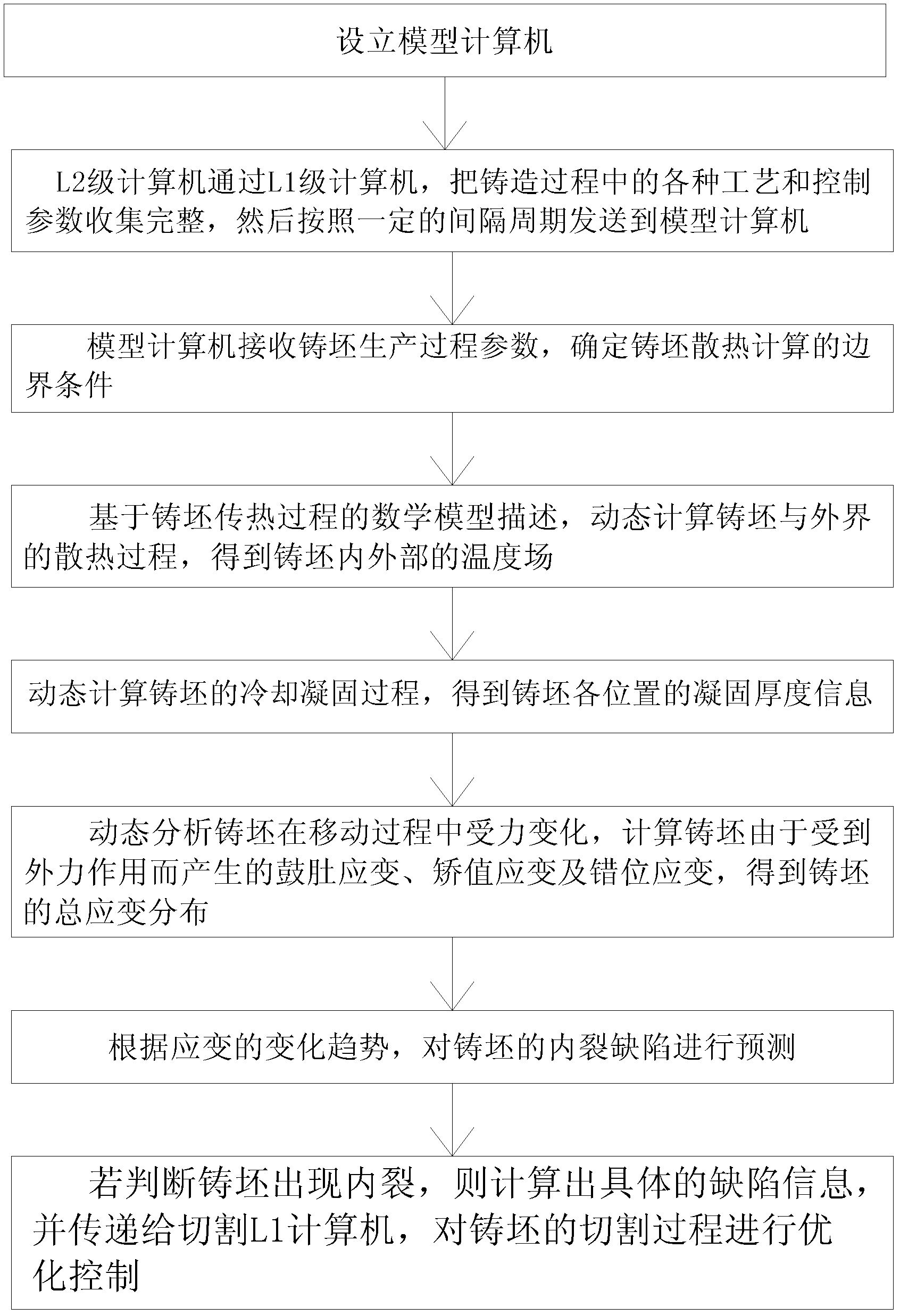

Method used

Image

Examples

Embodiment

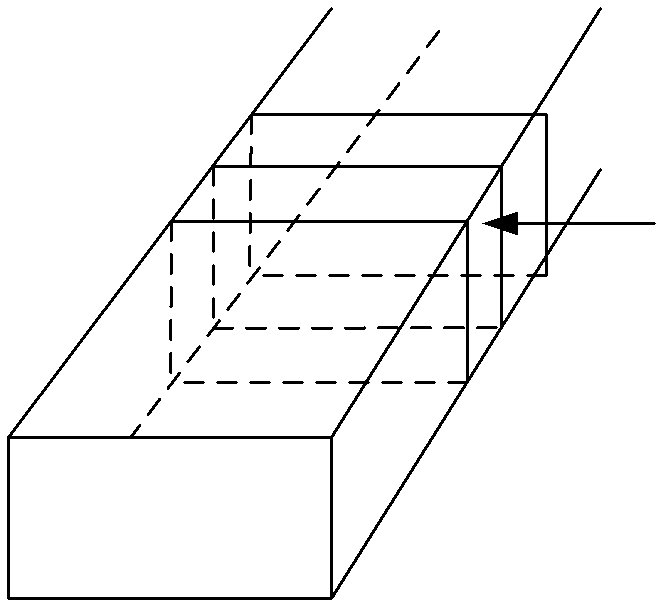

[0201] The vertical bending slab continuous casting machine of a steel plant has one machine and two streams, and the product specifications are mainly 220mm×1930mm.

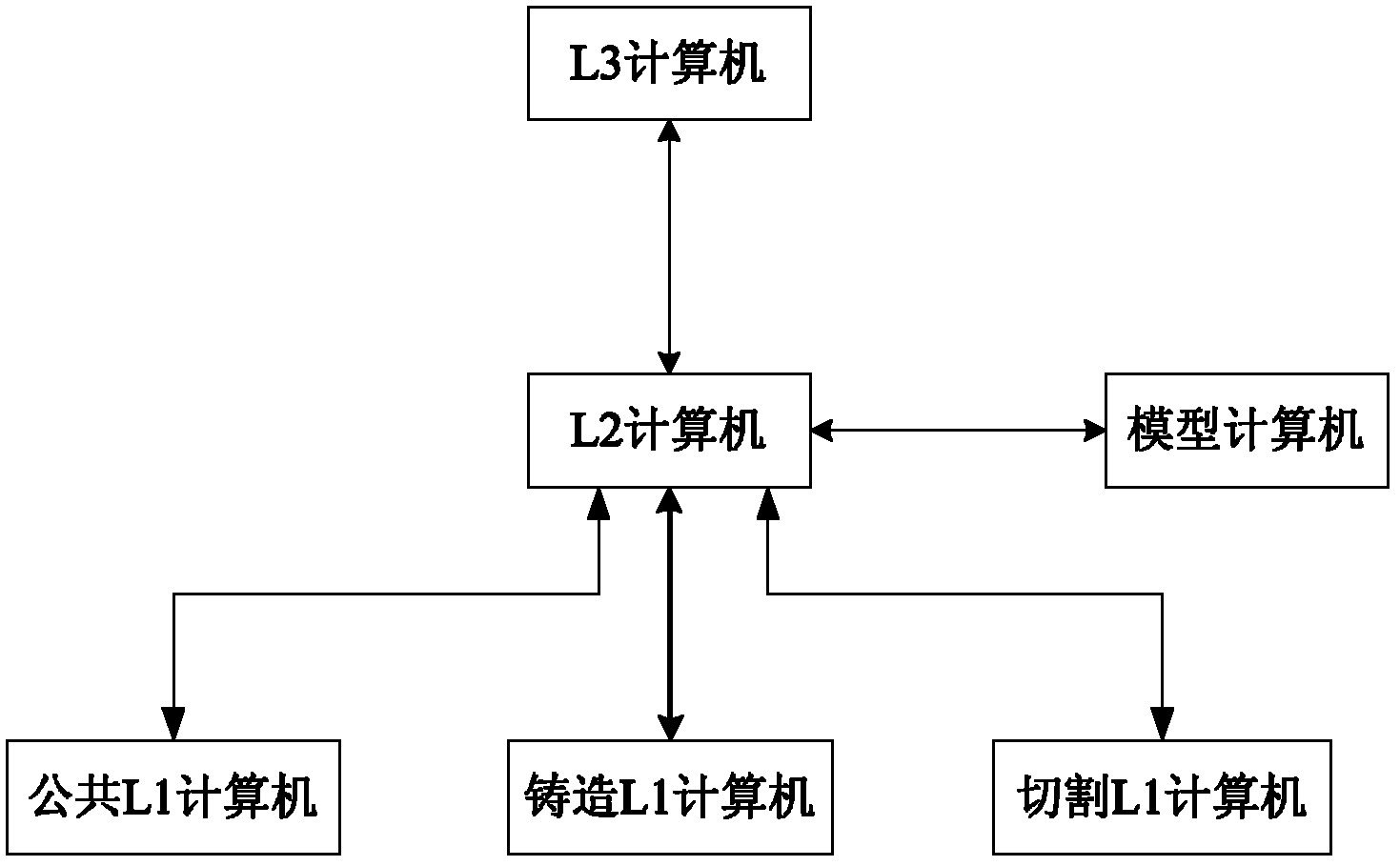

[0202] The composition of its production control system is shown in the appendix of the manual. figure 2 shown.

[0203] During the production process, the L3-level computer is responsible for issuing production planning instructions, and the L2-level computer is responsible for determining various control parameters in the production process according to the production plan, and sending the control parameters to the L1-level computer for execution; on the other hand, the L2-level computer passes The L1 computer collects all kinds of process and control parameters in the casting process, and then sends them to the model computer according to a certain cycle.

[0204] The model computer dynamically tracks and calculates the strain state of the billet according to the current process data.

[0205] When the mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com