Movable inclined platform type automatic steel bar bending machine

A bending machine and inclined table technology, applied in the field of mobile inclined steel bar automatic bending machines, can solve the problems of excessively large shape of the steel bar automatic bending machine, the limitation of the minimum bending size, and the complicated machine operation process, so as to overcome the bending operation and operation. The effect of easy, user-friendly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

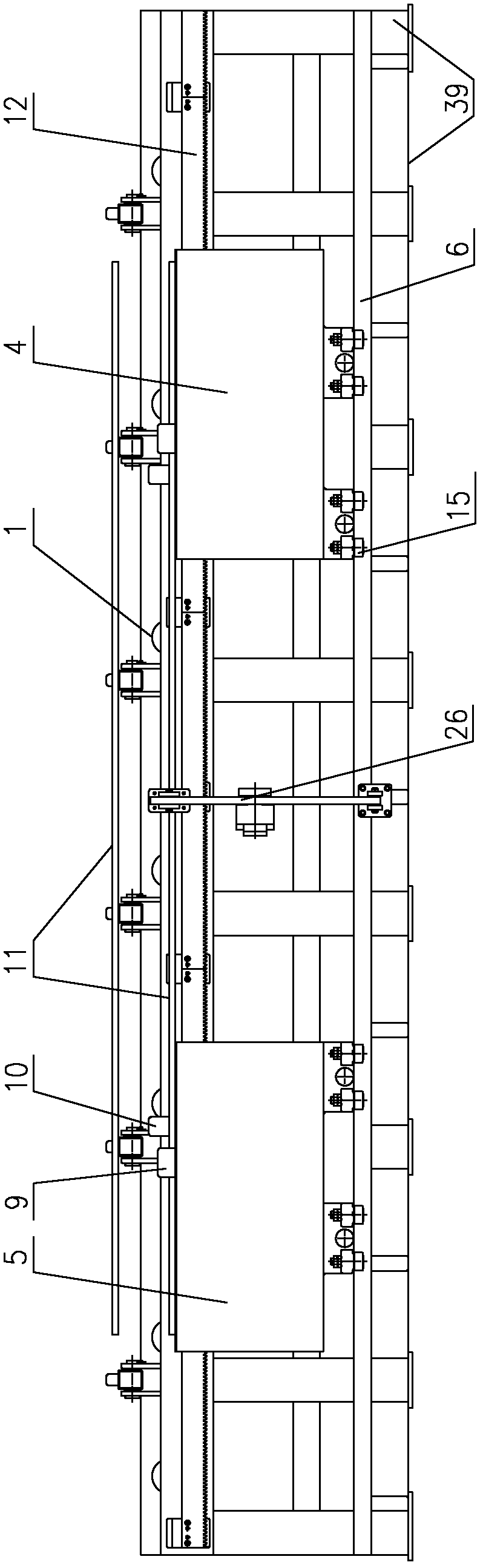

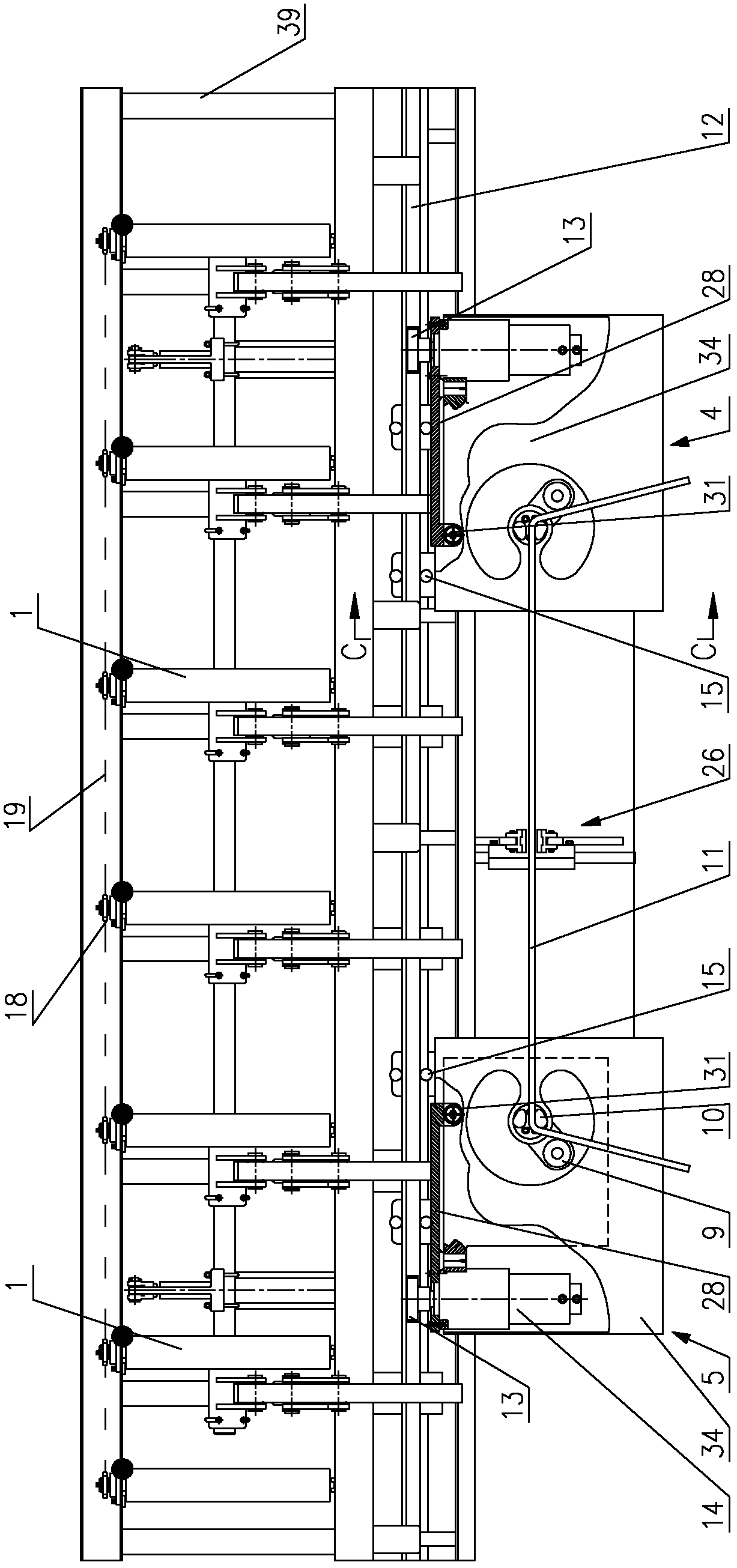

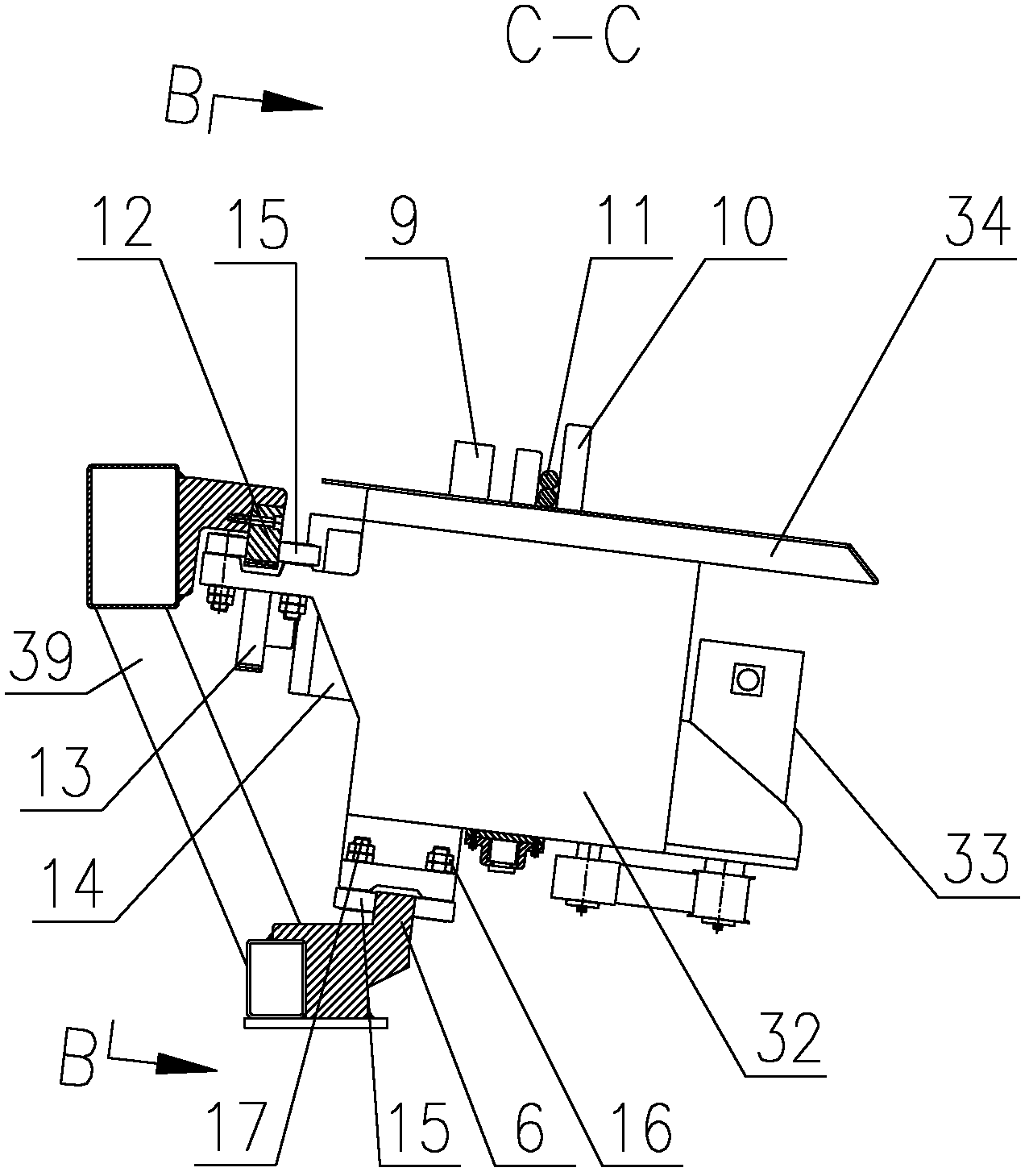

[0020] figure 1 is the front view of the present invention; figure 2 Yes figure 1 top view of image 3 Yes figure 1 Middle C-C sectional view; Figure 4 Yes image 3 Middle B-B sectional view.

[0021] As shown in the figure, the present invention provides a mobile inclined table type steel bar automatic bending machine, which includes: a frame 39; a track 6 and a rack 12 arranged on the frame 39; The first steel bar automatic bending machine 4 and the second steel bar automatic bending machine 5 that move with rack 12.

[0022] The first automatic steel bar bending machine 4 and the second steel bar automatic bending machine 5 are respectively provided with a gear transmission mechanism and a gear floating mechanism that move along the rack 12 .

[0023] The gear floating mechanism includes: a motor connection plate 28 and a support shaft 29; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com