a twister

A technology of folding line and baseline, applied in the field of folding machine, can solve the problems of high labor intensity of staff, large influence of human factors, difficult wire shape, etc., and achieve the effect of improving wiring effect, shortening bending time, and simple and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

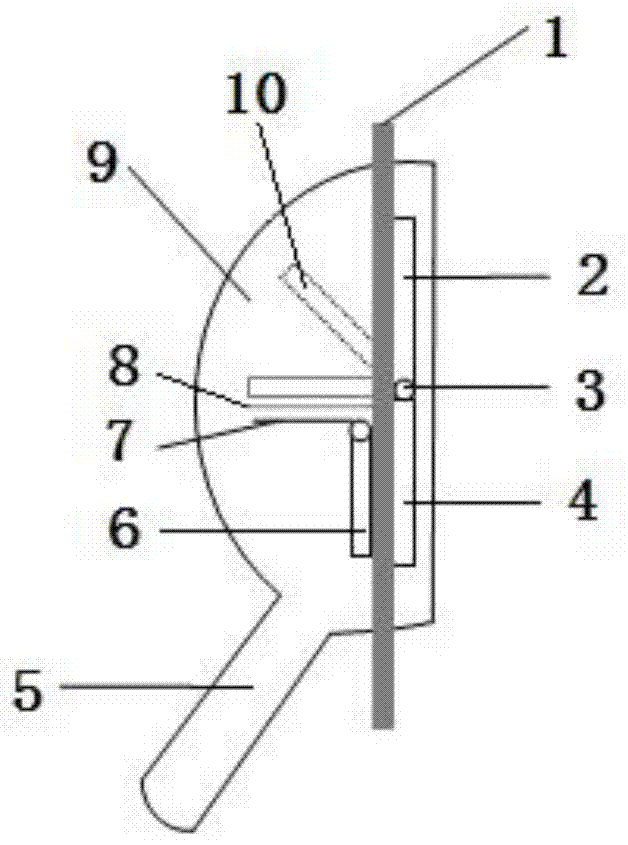

[0016] A line folding device includes two parts, a bottom support and a rotating system. The bottom support is composed of a handle 5 and an angle marking plate 9. The angle marking plate is semicircular, and the handle is connected to the side of the arc edge of the angle marking plate.

[0017] The rotating system comprises a common fixed piece 4, a pressure rotating piece 2 and an elastic fixed piece. An ordinary fixed piece is installed on the angle marking plate, which is arranged in the same direction as the straight side of the angle marking plate, and a pressing rotary piece is hinged on the angle marking plate through the rotating shaft 3, and the pressing rotating piece is connected to the straight edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com