Three-dimensional simulation method for chemical vapor deposition process

A technology of chemical vapor deposition and simulation method, which is applied in the field of deposition process simulation in microelectronics processing, can solve problems such as inaccurate simulation and single constituent materials, and achieve the effect of solving single constituent materials and avoiding blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention proposes a three-dimensional simulation method of a chemical vapor deposition process, which is described in detail in conjunction with the accompanying drawings and implementation as follows:

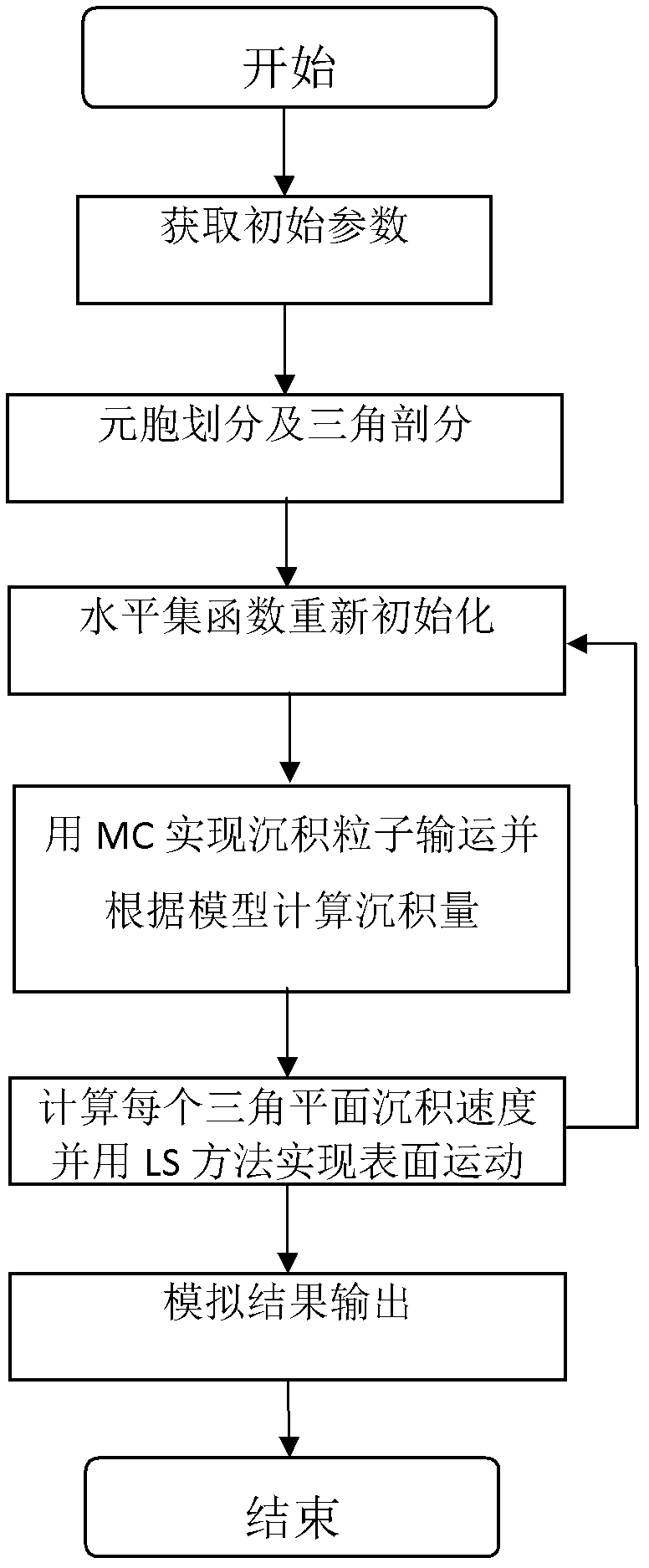

[0012] The overall flow of the method of the present invention is as follows figure 1 As shown, the specific implementation method includes the following steps:

[0013] 1) Obtain initial parameters: According to the actual processing equipment and deposition gas, estimate and calculate the electric field boundary parameter E c , the type S and number N of particles participating in the deposition s and velocity distribution P v ;Input the simulation area Ω and the deposition graph Γ; set the cell side length l; set the simulation time T; set the maximum advancing distance dist;

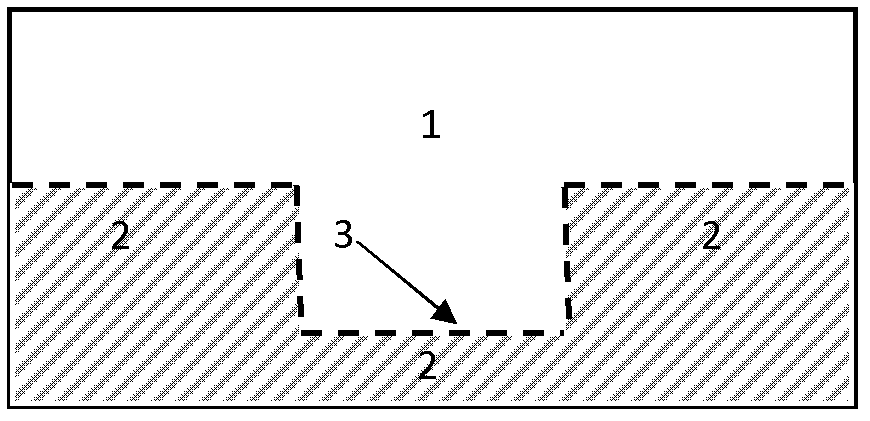

[0014] 2) Divide the simulation area Ω into cells, and divide it into multiple cells, each cell corresponds to the material at the position, and obtain the corresponding materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com