Blasting method based on joint control of hole inside energy accumulation blasting and smooth blasting

A technology of smooth blasting and joint control, applied in blasting and other directions, can solve problems such as inability to adapt to retained rock mass, and achieve the effect of reducing support workload, improving project quality, and reducing project costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

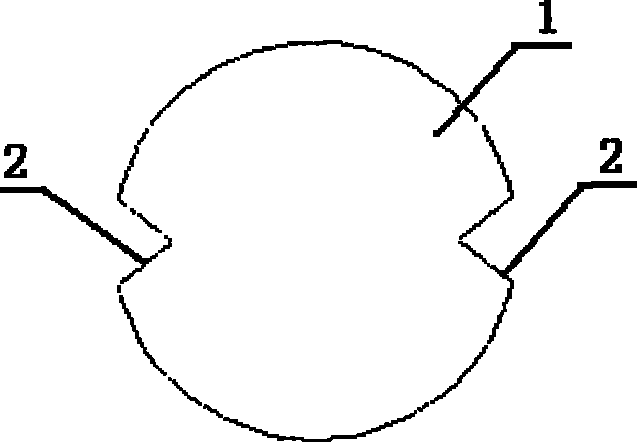

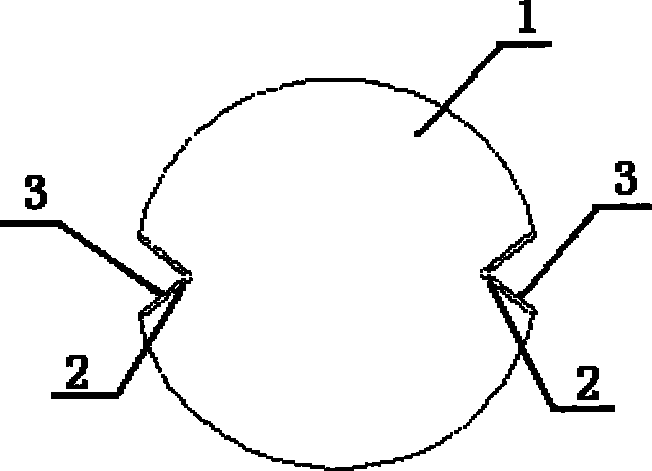

[0034] The combined control blasting method of cohesive energy blasting and smooth surface blasting in embodiment 1 (see Figure 1~2 , Figure 4~6 ), including the following steps:

[0035] (1) Delineate the peripheral contour line of the blasting excavation area according to the design requirements of the differential blasting, and arrange the differential blasting holes in the main blasting excavation area 7 .

[0036] (2) Arrange smooth blasting holes 10 along the peripheral contour of the blasting excavation area.

[0037] Wherein: the diameter of the smooth blast hole 10 is 38-42 mm.

[0038] (3) Reserve the smooth surface layer 8 within the contour line of the blasting excavation area and arrange energy-concentrating blast holes 5 in the holes on the side of the main blasting excavation area 7; the thickness of the reserved smooth surface layer 8 is: blasting excavation The distance between the retained rock mass wall 9 to be formed around the area and the plane forme...

Embodiment 2

[0049] The combined control blasting method of cohesive energy blasting and smooth surface blasting in embodiment 2 (see Figure 1~2 , Figure 4~6 ), including the following steps:

[0050] (1) Delineate the peripheral contour line of the blasting excavation area according to the design requirements of the differential blasting, and arrange the differential blasting holes in the main blasting excavation area 7 .

[0051] (2) Arrange smooth blasting holes 10 along the peripheral contour of the blasting excavation area.

[0052] Wherein: the diameter of the smooth blast hole 10 is 38-42 mm.

[0053] (3) Reserve the smooth surface layer 8 within the contour line of the blasting excavation area and arrange energy-concentrating blast holes 5 in the holes on the side of the main blasting excavation area 7; the thickness of the reserved smooth surface layer 8 is: blasting excavation The distance between the retained rock mass wall 9 to be formed around the area and the plane forme...

Embodiment 3

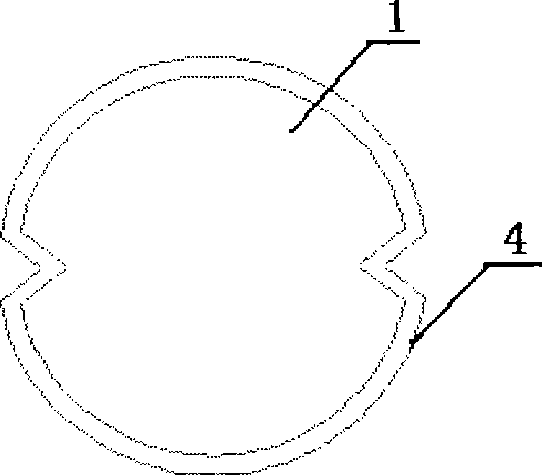

[0064] The combined control blasting method of cohesive energy blasting and smooth surface blasting in embodiment 3 (see figure 1 , Figure 3-6 ), including the following steps:

[0065] (1) Delineate the peripheral contour line of the blasting excavation area according to the design requirements of the differential blasting, and arrange the differential blasting holes in the main blasting excavation area 7 .

[0066] (2) Arrange smooth blasting holes 10 along the peripheral contour of the blasting excavation area.

[0067] Wherein: the diameter of the smooth blast hole 10 is 38-42 mm.

[0068] (3) Reserve the smooth surface layer 8 within the contour line of the blasting excavation area and arrange energy-concentrating blast holes 5 in the holes on the side of the main blasting excavation area 7; the thickness of the reserved smooth surface layer 8 is: blasting excavation The distance between the retained rock mass wall 9 to be formed around the area and the plane formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com