Free piston expander

An expander and piston technology, applied in the field of low-temperature refrigeration, can solve the problems affecting the use of refrigerators, complex structure, adverse effects on life and vibration indicators, etc., and achieve the effects of small axial stiffness, reduced energy consumption, and large radial stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

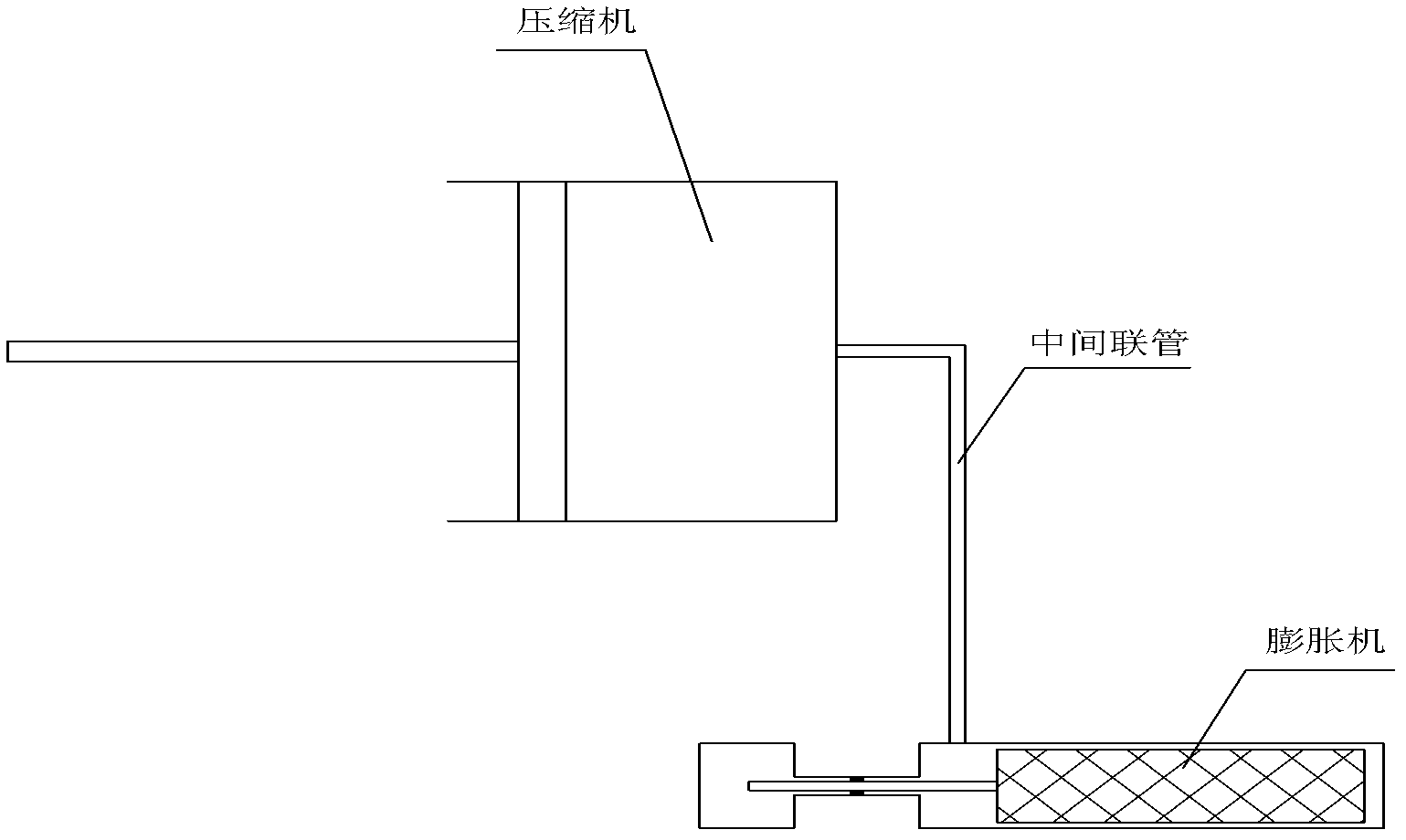

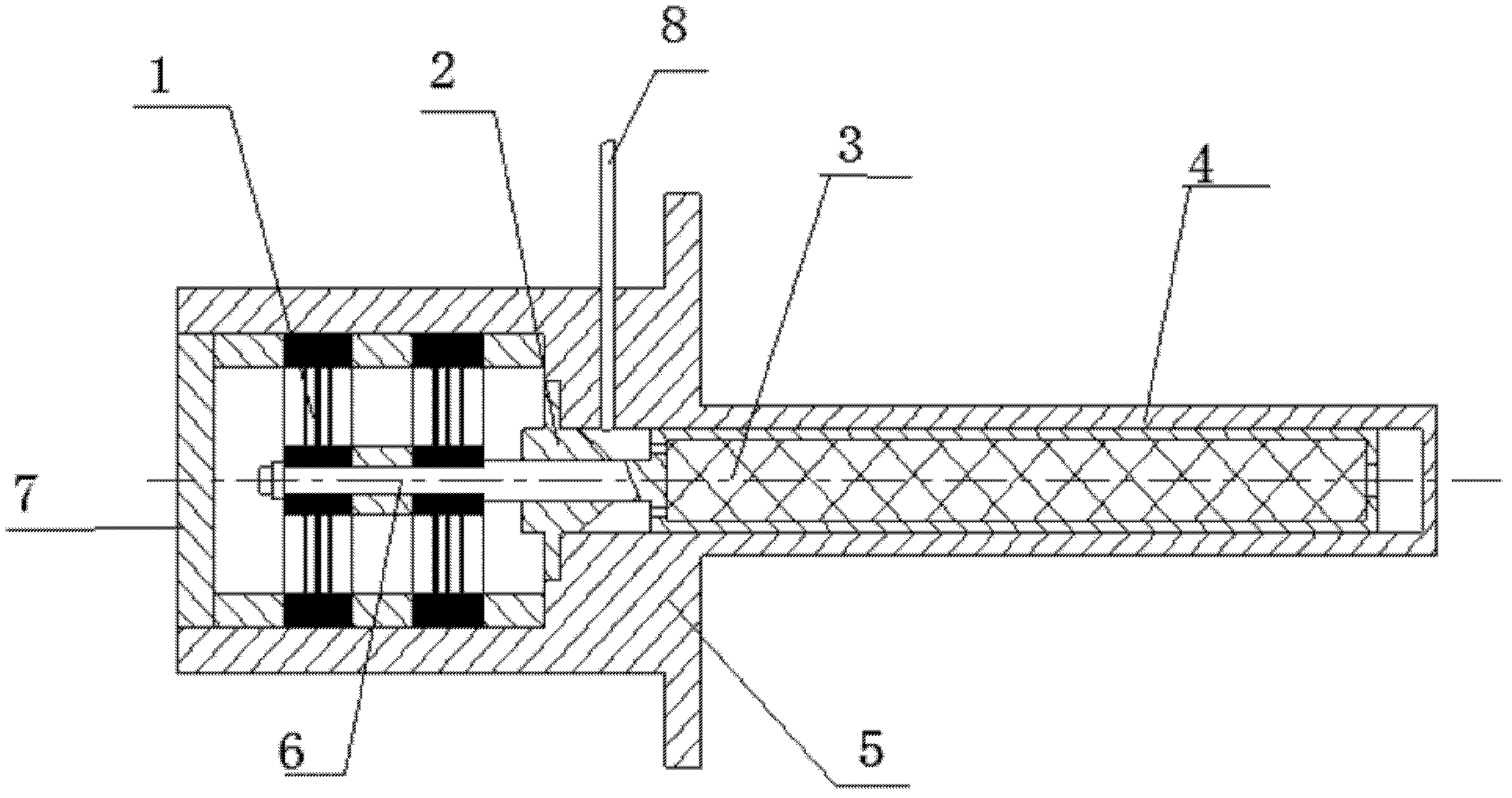

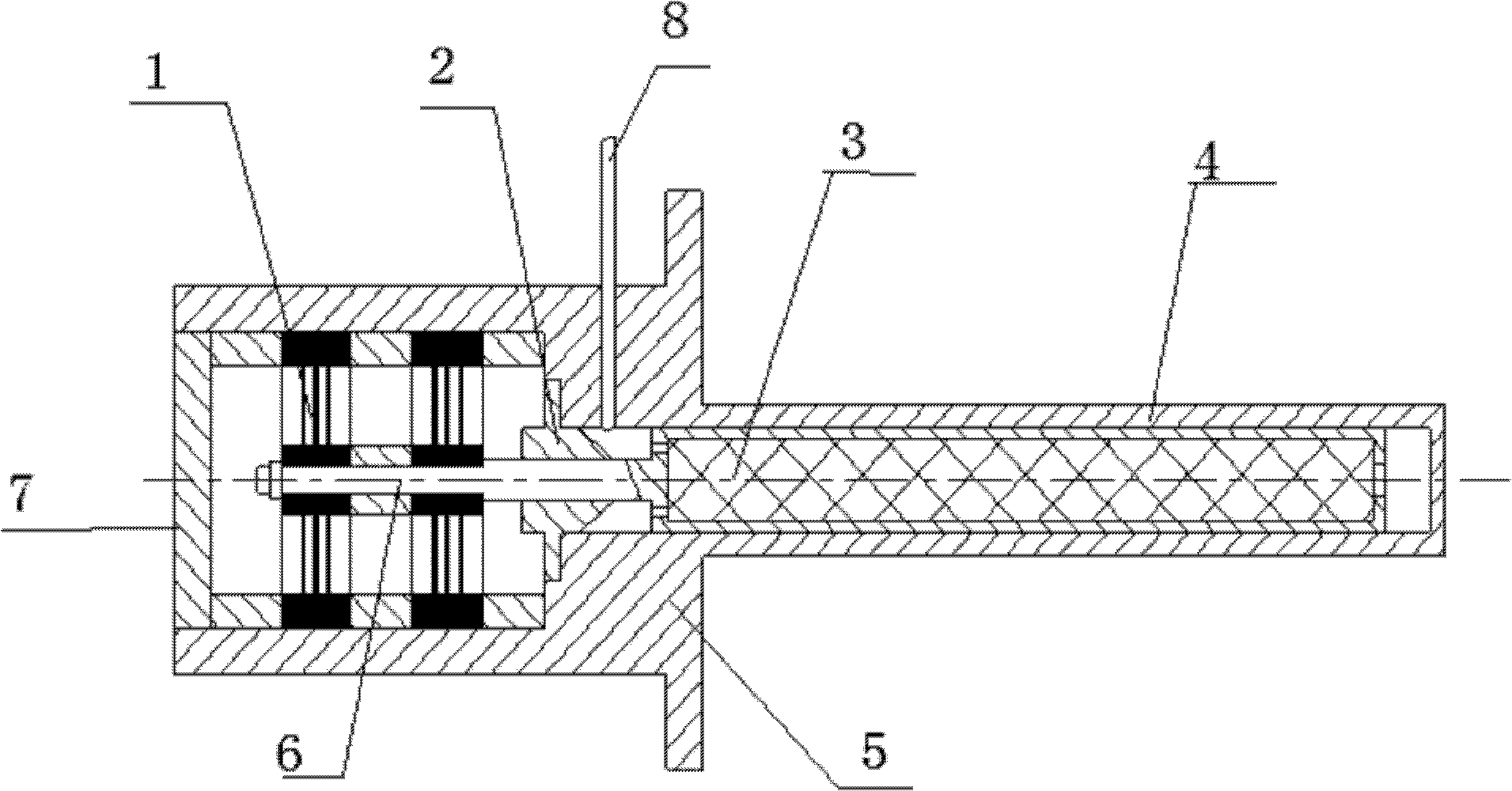

[0026] Such as figure 2 A free-piston expander is shown, and the expander includes: a plate spring 1, a gap seal seat 2, a regenerator 3, a cold finger 4, a cold cylinder 5, a drive rod 6, an end cover 7, a connecting pipe 8 and Peripheral compressors;

[0027] Wherein the cold cylinder 5 and the cold finger 4 are both cylindrical cavity structures, the diameter of the cold finger 4 is 1 / 5 to 1 / 3 of the cold cylinder 5, the cold cylinder 5 and the cold finger 4 are integrally structured, one end of the cold cylinder 5 and One end of the cold finger 4 is fixedly connected and the inner cavity is connected, and the other end of the cold cylinder 5 is welded with an end cover 7. The cold cylinder 5 and the end cover form a back pressure chamber, and one or more are placed in the back pressure chamber along the longitudinal axis of the cold cylinder 5 The leaf spring 1 has a hole in the center of the leaf spring 1, and the two ends are fixed on the cold cylinder 5;

[0028] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com