Adjustment support for industrial video camera

A technology for adjusting brackets and cameras, which is applied in the direction of machines/brackets, supporting machines, mechanical equipment, etc. It can solve the problems of limited adjustment range, inapplicability, and restrictions on the highest and lowest positions of the camera, so as to ensure stability and facilitate movement , easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

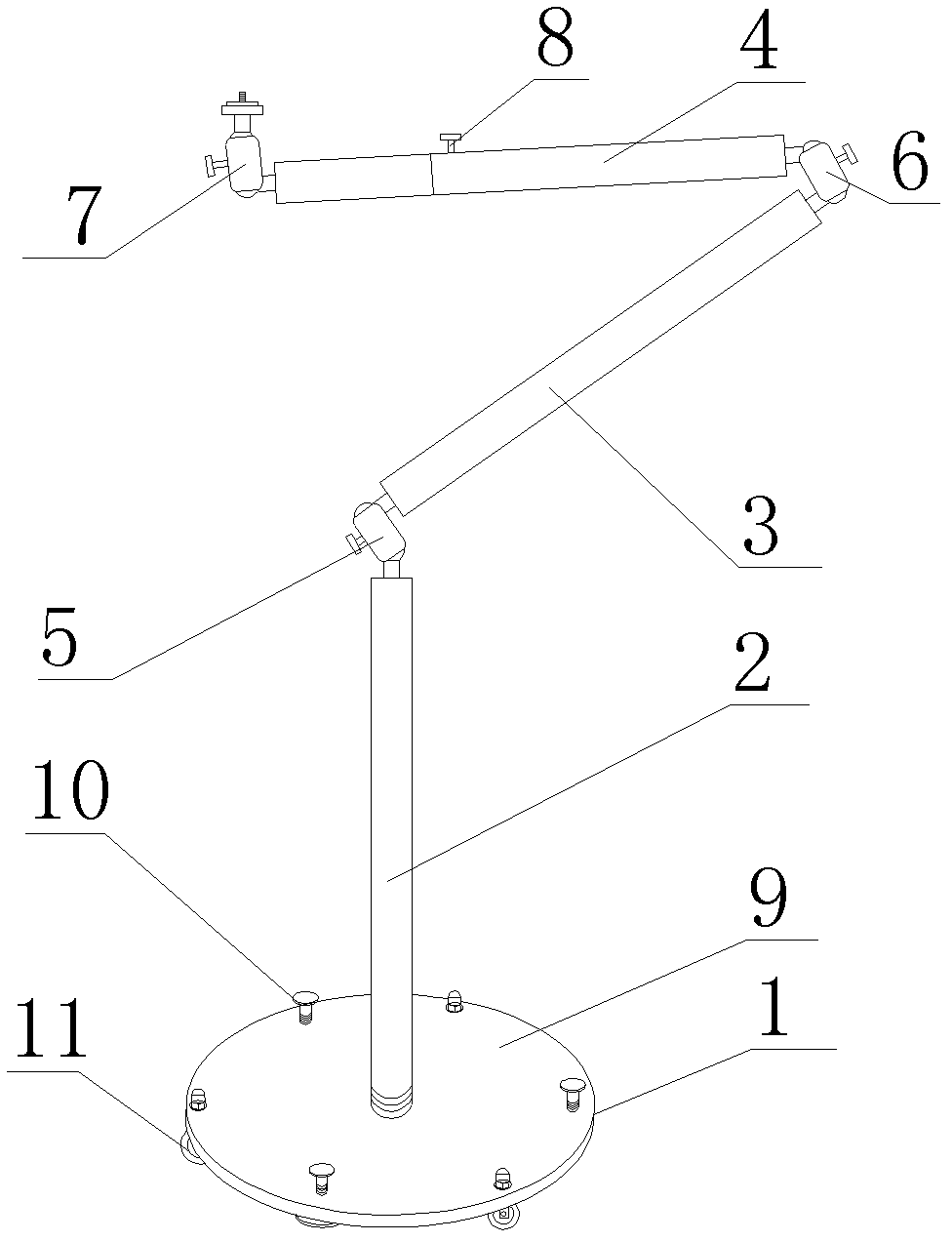

[0036] In order to achieve rotation with more degrees of freedom, without adjusting the support rod and the base at the same time, and to expand the adjustment range, the embodiment of the present invention provides an adjustment bracket for industrial cameras, see figure 1 , see the description below:

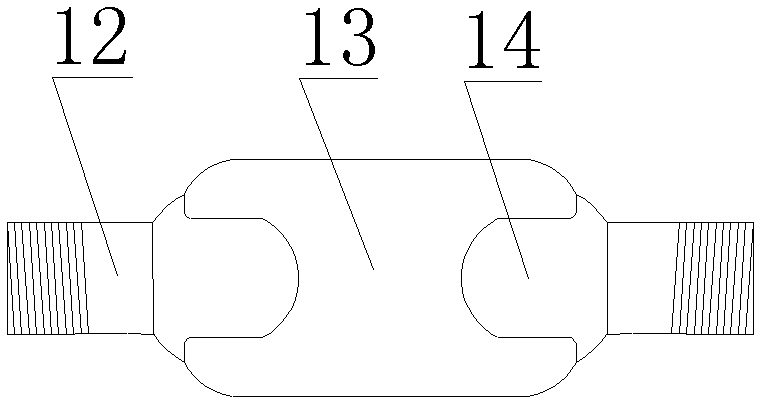

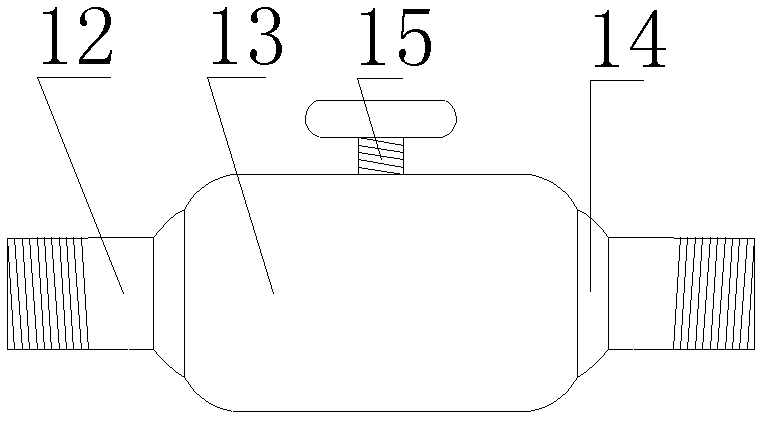

[0037] An adjustment bracket for an industrial camera, comprising: a base 1, which is threadedly connected to one end of a first support rod 2; the other end of the first support rod 2 is connected to a second support rod through a first spherical universal joint 5 3; the other end of the second support rod 3 is connected with an end of the telescopic rod 4 by the second spherical universal joint 6; the other end of the telescopic rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com