Passive low-frequency vibration isolator

A vibration isolator and low-frequency technology, applied in the field of passive low-frequency vibration isolators, can solve the problem that vibration isolation and anti-shock devices are difficult to achieve working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

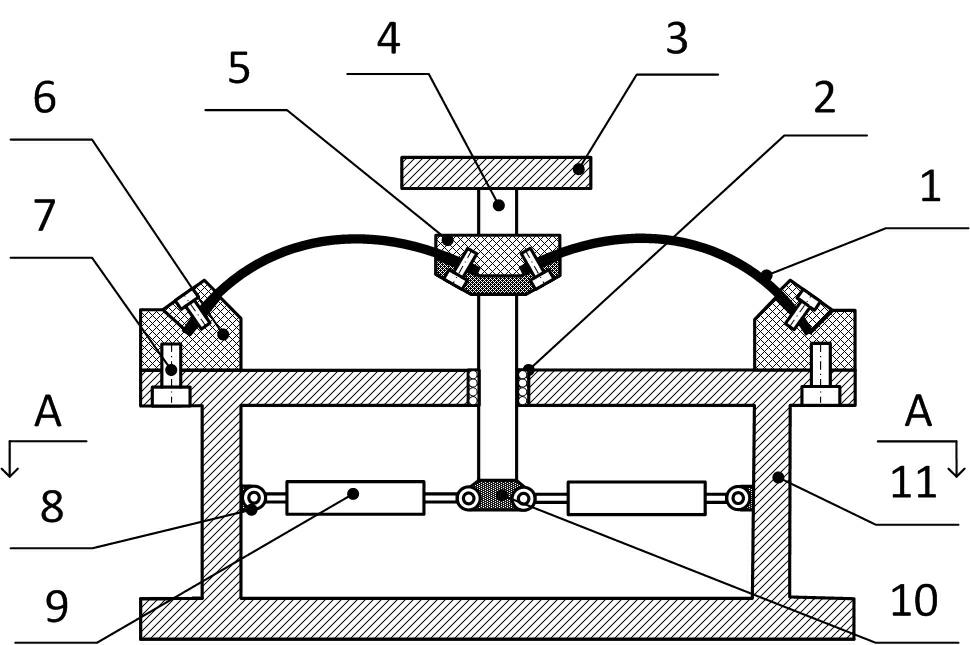

[0023] see figure 1 , a passive low-frequency vibration isolator includes a closed cylindrical base 11, the base 11 is a closed cavity, which can effectively prevent dust and water for the structure in the cavity. A through hole is opened in the middle of the top of the base 11, and a linear bearing 2 is installed in the through hole. On the side wall in the base 11, three base joints 8 are evenly distributed, and the three base joints 8 are respectively connected to the connecting rods of the cylinder ends of the three dampers 9; the connecting rods of the damper 9 cylinders are connected to The inner side walls of the base 11 are hingedly connected. The central connecting rod 4 is inserted into the through hole of the base 11, and the central connecting rod 4 is slidingly matched with the linear bearing 2 to ensure smooth movement; The piston rod of the device 9; in order to realize the self-adjusting function of damping, three dampers 9 are symmetrically distributed to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com