#-shaped front sub frame

A front subframe, well-shaped technology, applied in the field of design and automobile manufacturing, can solve the problems of difficulty in increasing the Z-direction stiffness, stress concentration at the welding seam, excessive weight, etc., to achieve improved strength and stiffness, good forming performance, Weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

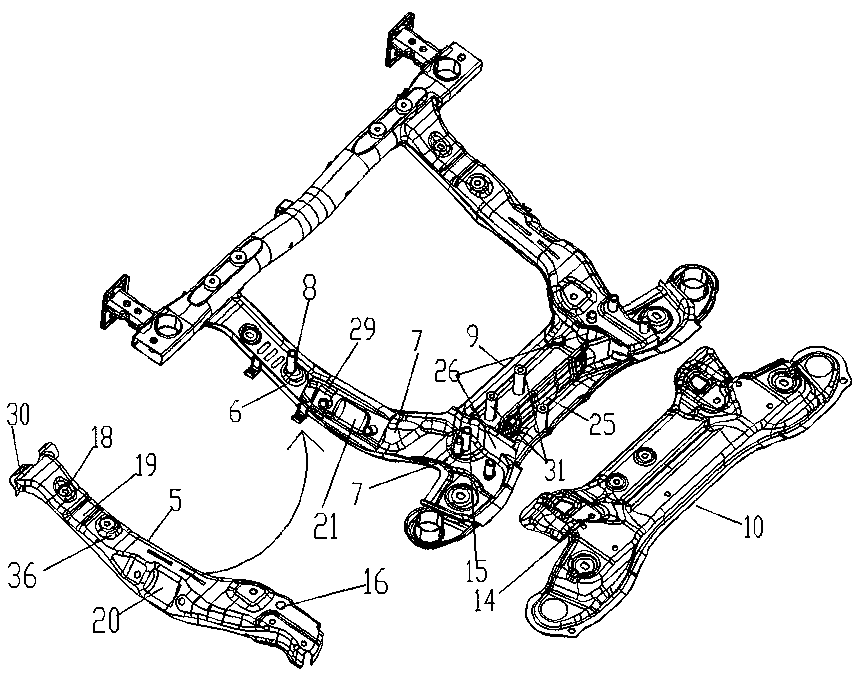

[0039] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is as preferred specific description:

[0040]It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer "respectively refer to towards or away from. If it is to describe the structure of the shell cavity, it is to describe the inside and outside of the shell, the direction of the geometric center of the invention or its specific components. The connection method specified in this embodiment is generally Welded connections, bolt or screw connections, snap-fit connections, snap-fit connections, etc. of the prior art are all prior technologies well known to those skilled in the art.

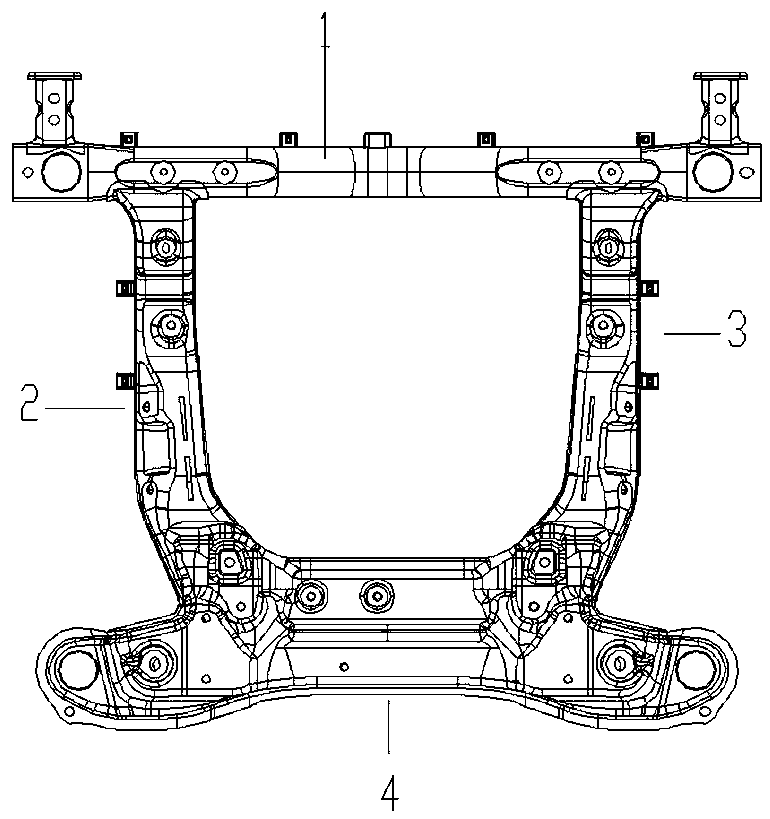

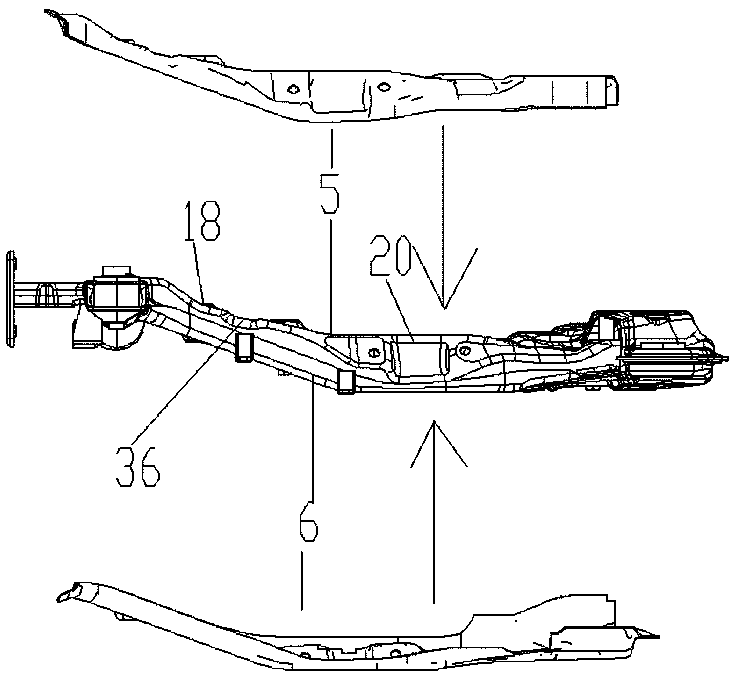

[0041] Such as figure 1 The well-shaped front auxiliary frame shown includes front beam (1), left side beam (2), right side beam (3), and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com