Adjustable quantitative injection pump

A quantitative injection and adjustable technology, applied in the field of syringe pumps, can solve the problems of injection and sampling pipeline pollution, troublesome control, high cost, etc., and achieve the effects of stable and reliable operation, simple control, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

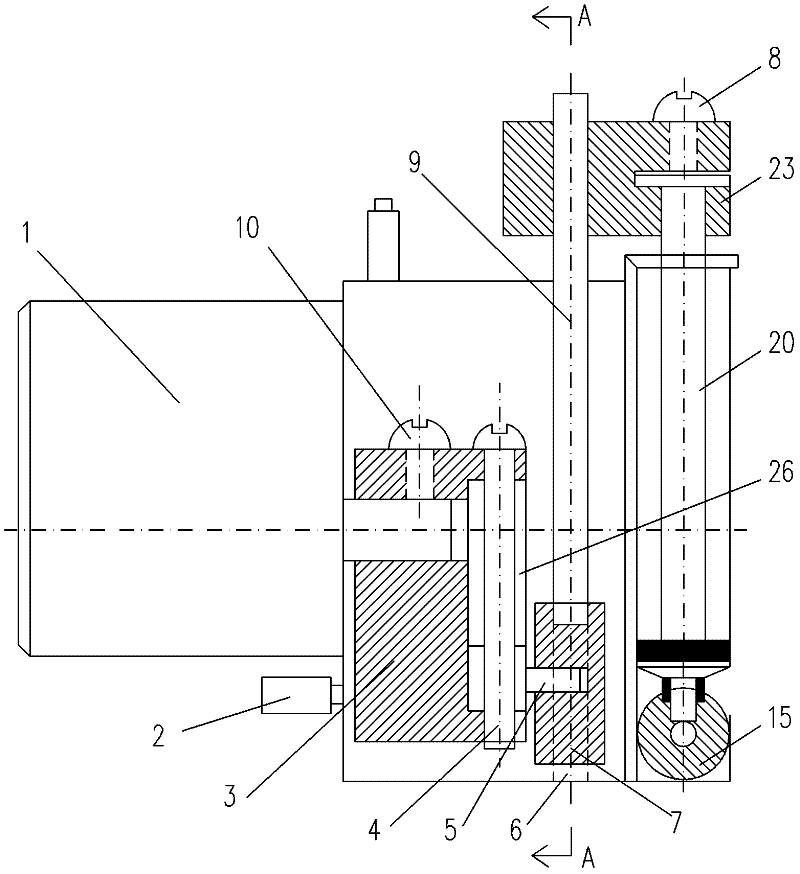

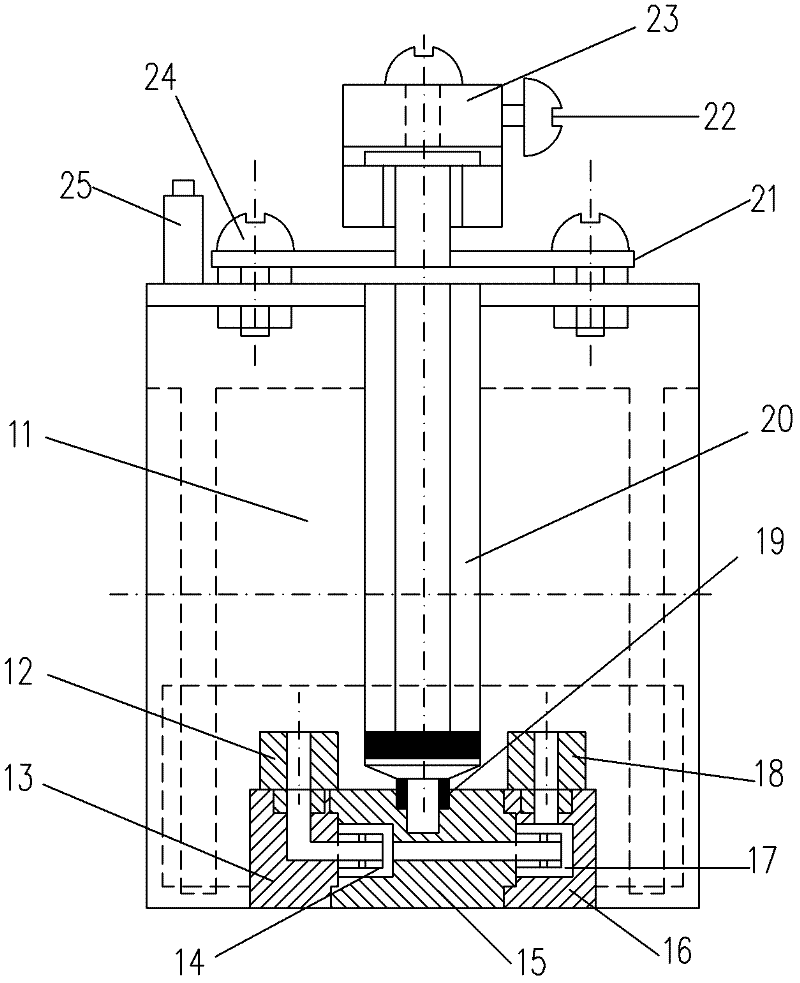

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Figure 1~Figure 4 Including geared motor 1, micro switch 2, rotating block 3, adjusting screw 4, slider transmission pin 5, slider guide rod 6, slider 7, syringe push rod fixing screw 8, transmission rod 9, rotation block fixing Screw 10, pump body 11, suction port 12, suction valve 13, suction valve film 14, discharge valve 15, discharge cavity 16, discharge valve film 17, discharge port 18, sealing ring 19, syringe 20, syringe pressure plate 21, linkage Block fixing screw 22, linkage block 23, pressure plate screw 24, manual switch 25, vertical groove 26, transverse groove 27 etc.

[0020] like Figure 1~Figure 3 As shown, the present invention is an adjustable quantitative injection pump, including a pump body 11, on which a reduction motor 1 is installed, and a rotation block 3 is fixed on the output shaft of the reduction moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com