System for tracking running state of underground plunger for gas production and working method thereof

A technology of running status and tracking system, which is applied in earthwork drilling, wellbore/well components, measurement, etc. It can solve the problem that the stuck depth cannot be calculated through the model, and the optimized production and predicted value of the plunger gas lift production well cannot be realized. The problem of discrepancy with the actual value and other problems, to achieve the effects of direct parameter collection and measurement tools and means, shortening invalid production time, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

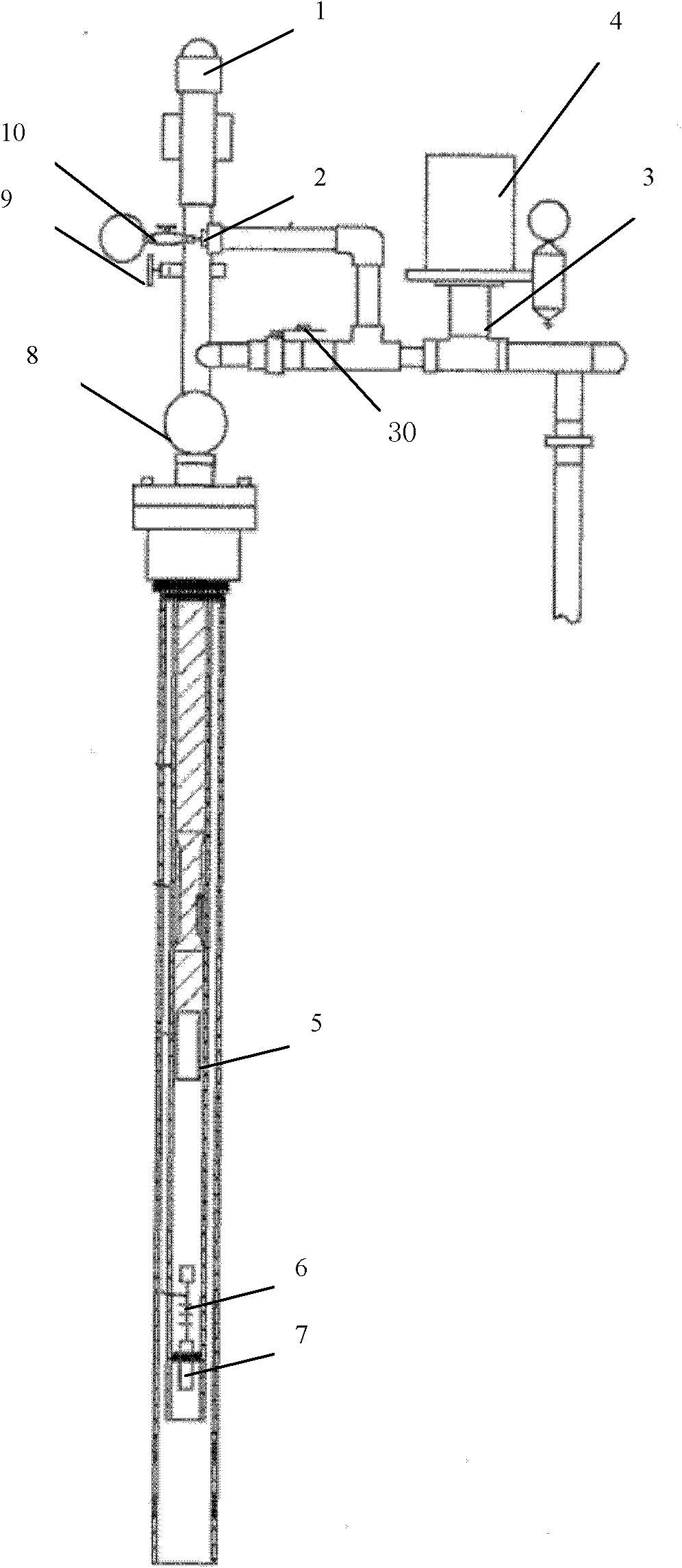

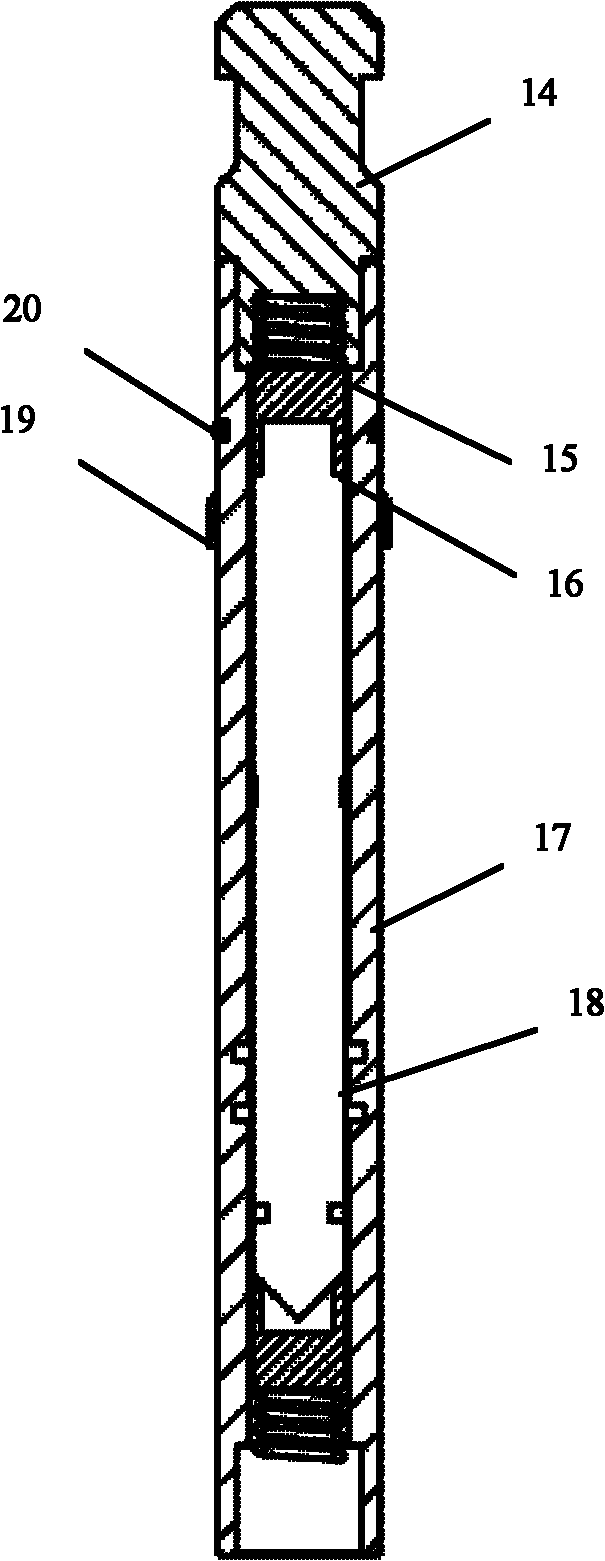

[0028] The present invention proposes a plunger downhole positioning and running state tracking system. The system includes a ground monitoring subsystem. The ground monitoring subsystem collects the acoustic pulse signal transmitted in the oil pipe in real time, and obtains the plunger operating parameters after processing and analyzing. To obtain the running status of the plunger in real time. At the same time, the invention also proposes a plunger downhole positioning and running state tracking method. The method is to collect and measure the acoustic pulse signal transmitted in the tubing in real time to obtain plunger operating parameters to identify the plunger operating state.

[0029] Preferably, the ground monitoring subsystem includes a plunger operation processing module, a ground display device, a ground system power supply, a ground acoustic wave transmitter, and a ground acoustic wave receiver; wherein, the plunger operation processing module is composed of other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com