Embedded conical bearing joint type steel structural support and construction method thereof

A construction method and steel structure technology, which is applied in the direction of building structure, formwork/formwork/work frame, and on-site preparation of building components, can solve problems such as slow progress, low construction efficiency, and no stress points, and achieve Accelerate the construction progress, low chance of rework, and good force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment one sees Figure 4 : the following of the other end of the steel beam 10 is supported by a wooden square 11.

Embodiment 2

[0042] Embodiment two see Figure 5 : The two ends of the steel beam 10 are respectively supported on two steel structure supports 7 .

[0043] The construction method of this kind of pre-embedded conical load bearing joint type steel structure support, the steps are as follows:

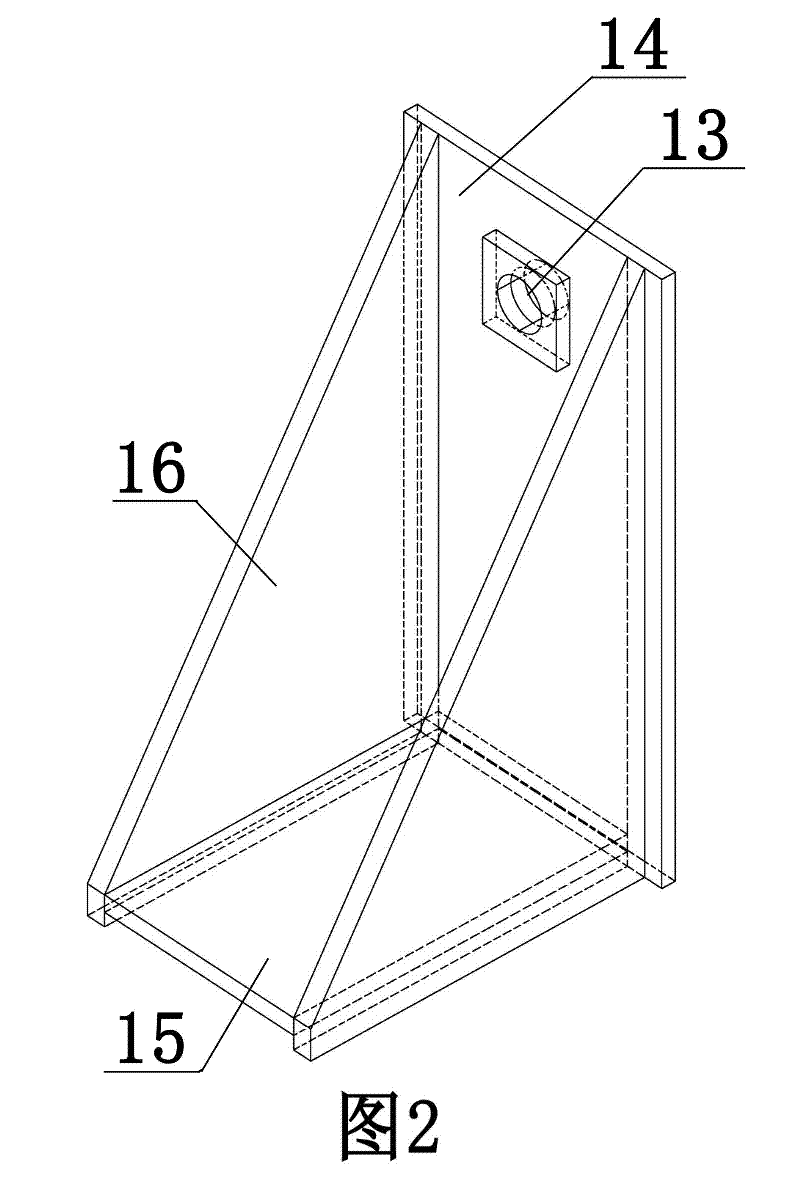

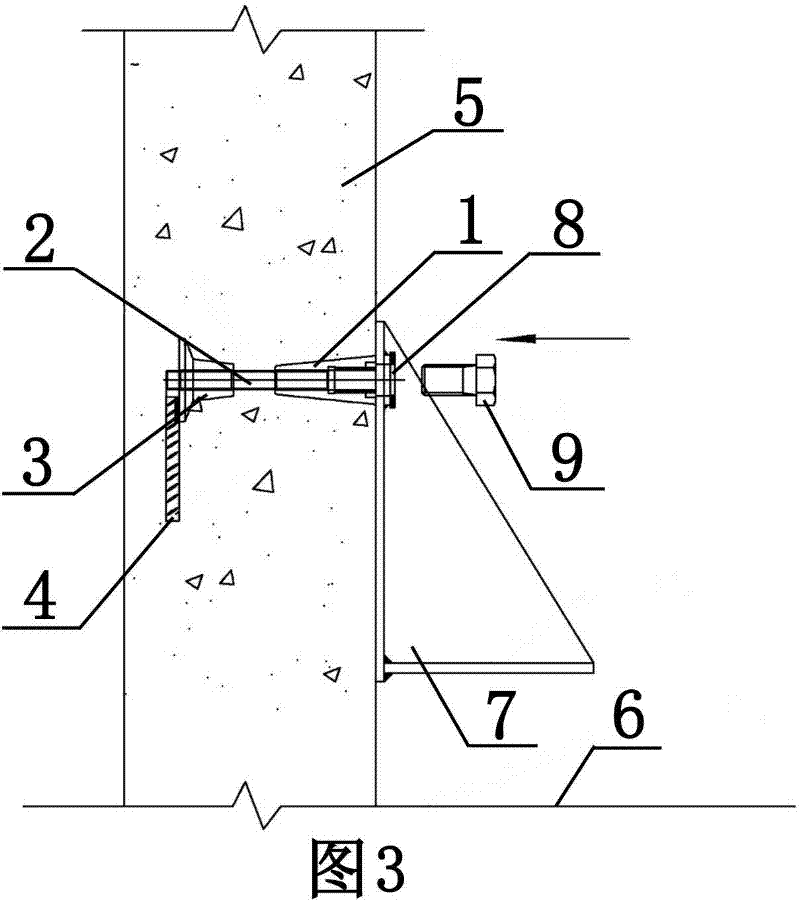

[0044] Step 1. Calculate the force load of the steel structure support 7 according to the area of the construction area 6 where it is inconvenient to erect the floor formwork support system, and determine its location and spacing according to the load; determine the model of the steel beam 10 according to the calculated load , and then use this to determine the specific size of the steel structure support 7, and process and manufacture the steel structure support 7; each steel plate of the steel structure support 7 needs to be fully welded on both sides, and the height of the welding angle is equal to the thickness of the thinner steel plate. The steel plate at the position of the bolt hole 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com