IF steel containing niobium and titanium for advanced automobile and annealing process

An automobile and advanced technology, applied in the field of metallurgy, can solve the problems of poor production flexibility, complex annealing process and high production cost, and achieve the effects of high production efficiency, low construction investment and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Put the slab to be rolled into the heating furnace. The chemical composition and weight percentage of the slab are: C 0.006%, Si 0.005%, Mn 0.14%, P 0.017%, S 0.004%, Alt 0.03%, Ti 0.012 %, Nb 0.023%, the rest is Fe and undetectable trace impurities.

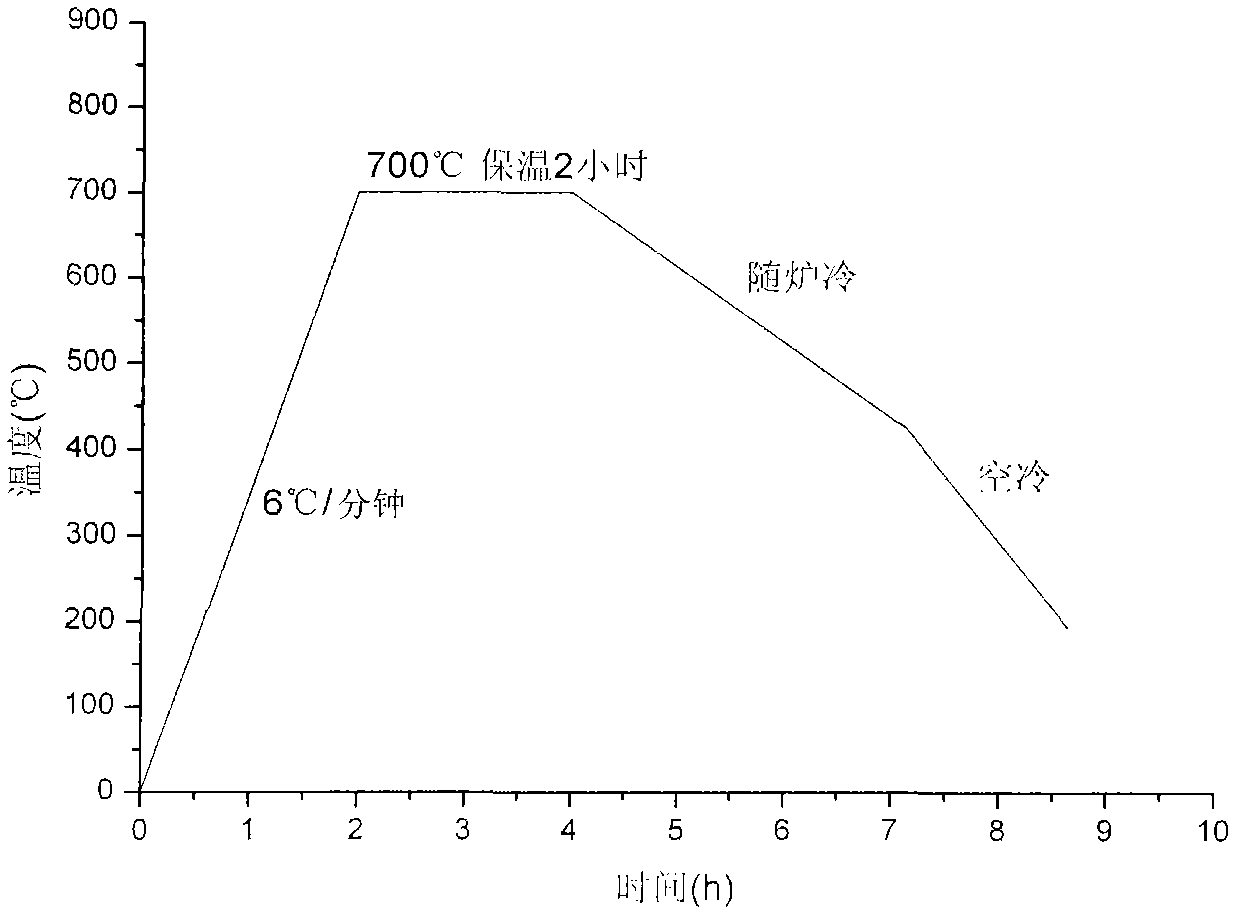

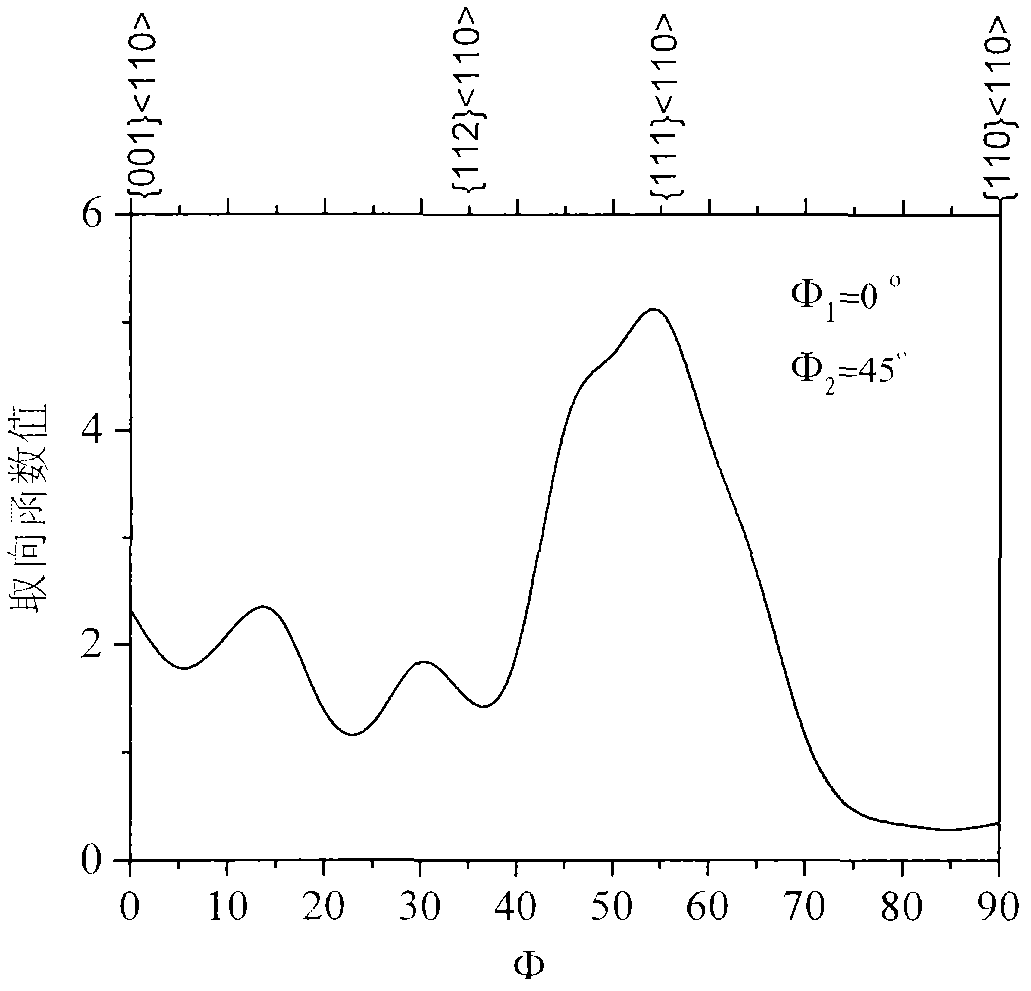

[0013] The heating rate is 6°C / min, the annealing temperature is 700°C, the holding time is 2 hours, and then the furnace is cooled to 450°C and air-cooled. The mechanical properties of the IF steel samples treated according to the above process are shown in Table 1, Table 2, and Table 3. The heating curve and sample texture are as follows: figure 1 , figure 2 shown. The {111} texture is dominant in the sample.

[0014] Table 1 Longitudinal mechanical properties and n, r value properties

[0015]

R P0.2 / MPa

Rm / MPa

R P0.2 / Rm

A%

n

r

126

310

0.41

42

0.26

1.95

147

310

0.47

44

0.268 ...

Embodiment 2

[0021] Put the slab to be rolled into the heating furnace. The chemical composition and weight percentage of the slab are: C 0.006%, Si 0.004%, Mn 0.147%, P 0.011%, S 0.004%, Alt 0.031%, Ti 0.013 %, Nb 0.018%, the rest is Fe and undetectable trace impurities.

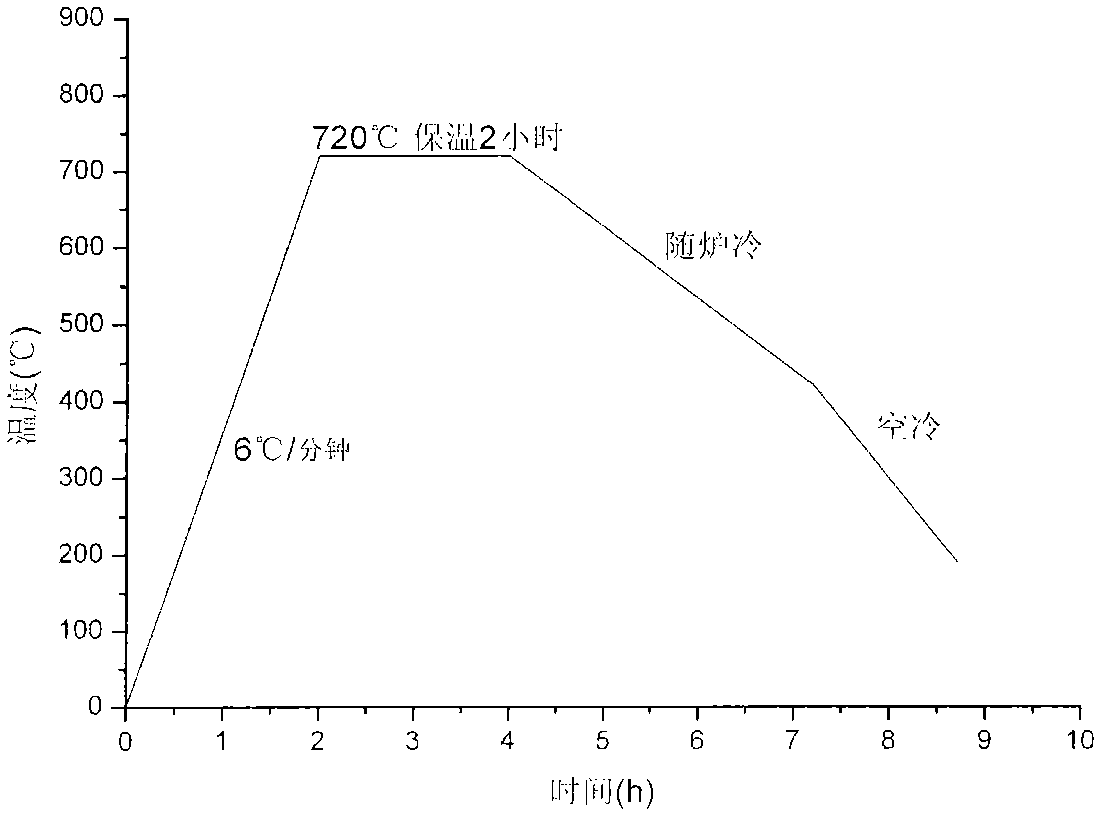

[0022] The heating rate is 6°C / min, the annealing temperature is 720°C, the holding time is 2 hours, and then it is cooled to 400°C with the furnace and air-cooled. The test values of the mechanical properties of the IF steel samples treated according to the above process are shown in Tables 4, 5, and 6. The heating curve and sample texture are as follows: image 3 , Figure 4 shown. The {111} texture is dominant in the sample.

[0023] Table 4 Longitudinal mechanical properties and n, r value properties

[0024] R P0.2 / MPa

Rm / MPa

R P0.2 / Rm

A%

n

r

137

325

0.42

49.5

0.25

2.12

137

325

0.42

49

0.25

2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com