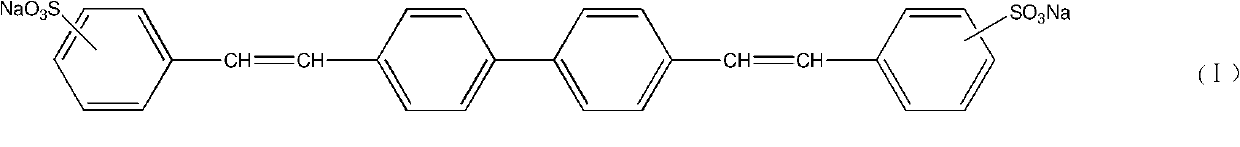

Preparing method of stilbene biphenyl fluorescent brightener

A technology of stilbene biphenyls and fluorescent whitening agents, which is applied in the preparation of detergent mixture compositions, chemical instruments and methods, and preparation of detergents by chemical methods, can solve the problems of precipitation and low solubility, and achieve The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of highly water-soluble stilbene biphenyl fluorescent whitening agent, characterized in that: the preparation method comprises the following steps:

[0024] (1) The active ingredients are 4,4'-bis-(2-sodium styryl)biphenyl and 4,4'-bis-(4-sodium styryl)biphenyl 1:1 500 kg of filter cake (wherein the solid content is 55%) is subjected to secondary refining of desalination: first place the filter cake in a reaction kettle, add 1500 kg of distilled water, and add 40 kg of monoethanolamine, heat until completely dissolved, and then heat filter , freeze to 5°C, precipitate crystals, press filter to obtain a cake filter; then put the cake filter into a reaction kettle, add 2000 kg of ethanol, first heat and reflux for 1 hour, then freeze to 5°C, precipitate crystals, press filter out and filter Cake is 450 kilograms (solid content 52%), and the salt content of this filter cake is 0.4%;

[0025] (2) The stage of beating the filter cake in the above step: ...

Embodiment 2

[0029] A preparation method of highly water-soluble stilbene biphenyl fluorescent whitening agent, characterized in that: the preparation method comprises the following steps:

[0030] (1) 50 wt% of 4,4'-bis-(2- Sodium sulfonate styryl) biphenyl 25wt%, 4,4'-bis-(4-sulfonate styryl) biphenyl 25wt% filter cake 500 kilograms (wherein solid content 55%) carry out desalination secondary Refining: first put the filter cake in a reaction kettle, add 1500 kg of distilled water, and add 40 kg of diethanol, heat until completely dissolved, heat filter, freeze to 5°C, precipitate crystals, press filter to obtain cake filter; The cake filter is put into the reaction kettle, 2000 kilograms of ethanol is added, heated and refluxed for 1 hour, then frozen to 5° C., crystals are precipitated, and 445 kilograms (solid content 53%) of the filter cake are filtered out by pressure filtration. The salt content of the filter cake is 0.35%;

[0031] (2) The stage of beating the filter cake in the ...

Embodiment 3

[0035] A preparation method of highly water-soluble stilbene biphenyl fluorescent whitening agent, characterized in that: the preparation method comprises the following steps:

[0036] (1) The active ingredient is 4-(2-sodium styryl sulfonate)-4'-(4-sodium styryl sulfonate)-biphenyl 40wt%, 4,4'-bis-(2-sulfonate Sodium styrene-acid styrene base) biphenyl 30wt%, 4,4'-bis-(4-sodium sulfonate styryl) biphenyl 30wt% filter cake 500 kilograms (wherein solid content 55%) carries out the secondary refining of desalination : First place the filter cake in a reaction kettle, add 1500 kg of distilled water, and add 40 kg of monoethanolamine, heat until completely dissolved, heat filter, freeze to 5°C, precipitate crystals, press filter to obtain cake filter; Put the cake filter into the reaction kettle, add 2000 kg of methanol, heat and reflux for 1 hour, then freeze to 5 ° C, crystals are precipitated, and the filter cake is 450 kg (solid content 52%) by pressure filtration. 0.4%;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com