Polyurethane strengthening water shutoff material special for mining and preparation method thereof

A technology of polyurethane and raw materials, which is applied in the field of polyurethane reinforced water blocking materials and its preparation, and polyurethane compositions. It can solve problems such as poor filling and reinforcement effects, high bonding strength, and difficult construction, so as to prevent and reduce accidents and reactions. The effect of low temperature and reduction of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 According to the following steps, the special polyurethane reinforced water blocking material for mining of the present invention is prepared

[0035] ①. Preparation of component A

[0036] Accurately metered polyoxypropylene tetrahydric alcohol 635H67 parts by weight with a hydroxyl value of 400-460 mgKOH / g, foam stabilizer H32015 parts by weight, flame retardant tris (2-chloropropyl) phosphate TCPP27 parts by weight, catalyst dilaurel Put 1 weight part of dibutyltin acid into the reaction kettle, stir and mix for 3 to 4 hours at room temperature, discharge, and seal the package;

[0037] ②. Preparation of component B

[0038] Accurately weigh 20 parts by weight of polyoxypropylene diol DL-40020 with a relative molecular weight of 400±10 and put it into a polymerization reactor. Under stirring, heat up to 80-100°C, vacuum dehydrate and degas for 2-3 hours, and cool down to 10-100°C. 40°C, put in 80 parts by weight of polymethylene polyphenyl polyisocyana...

Embodiment 2~ Embodiment 5

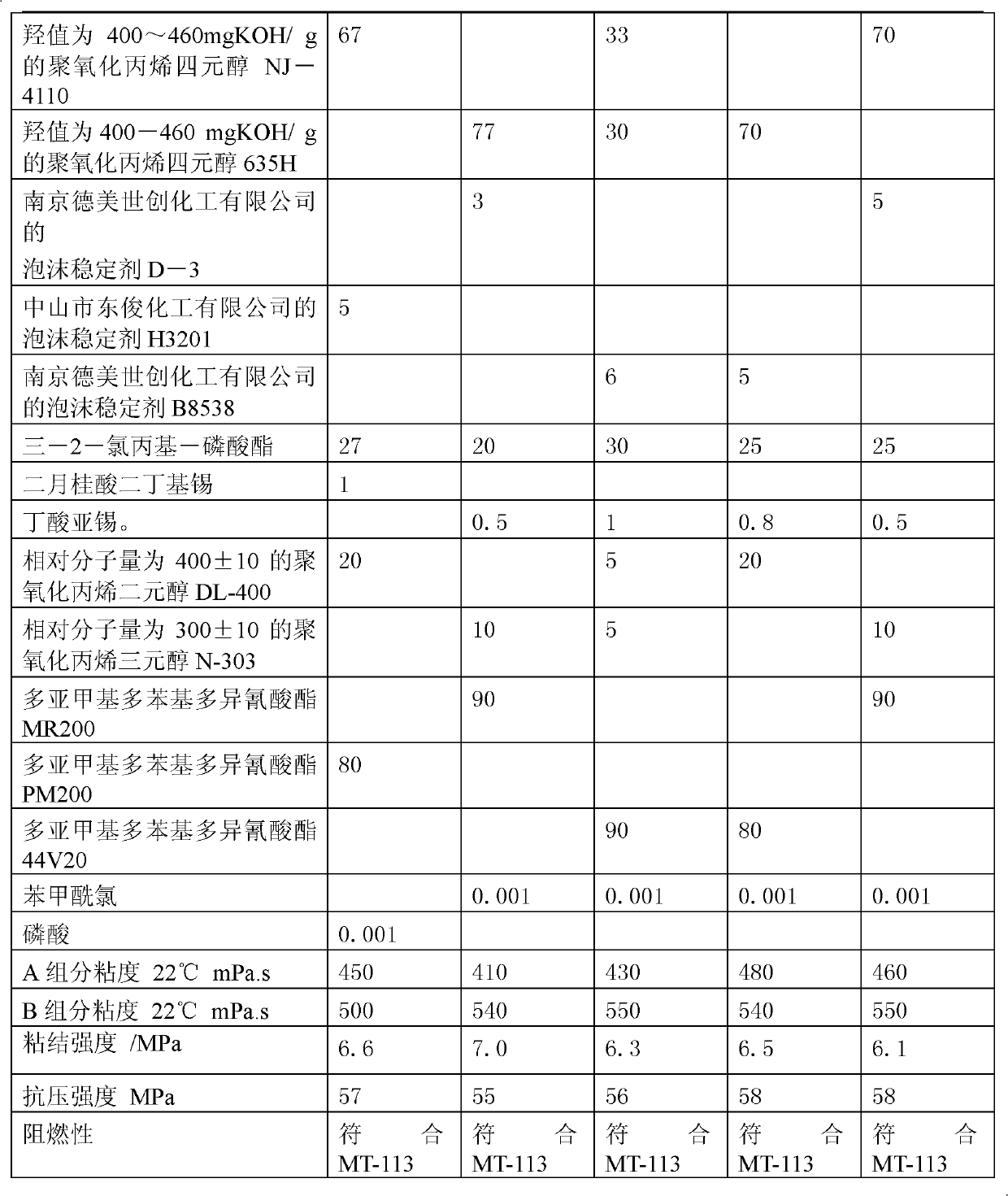

[0041] According to the method and steps of Example 1, the special polyurethane reinforced water blocking material for mining of the present invention is prepared according to the formula in Table 1

[0042] Table 1

[0043]

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com