Technology for repeatedly drying, stacking and baking bricks

A multi-drying and process technology, applied in the field of mechanical brick making of building materials, can solve the problems of low utilization rate of the kiln chamber, deformation and collapse of the green body, and achieve the effect of solving serious deformation and collapse, improving the compressive strength and increasing the output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

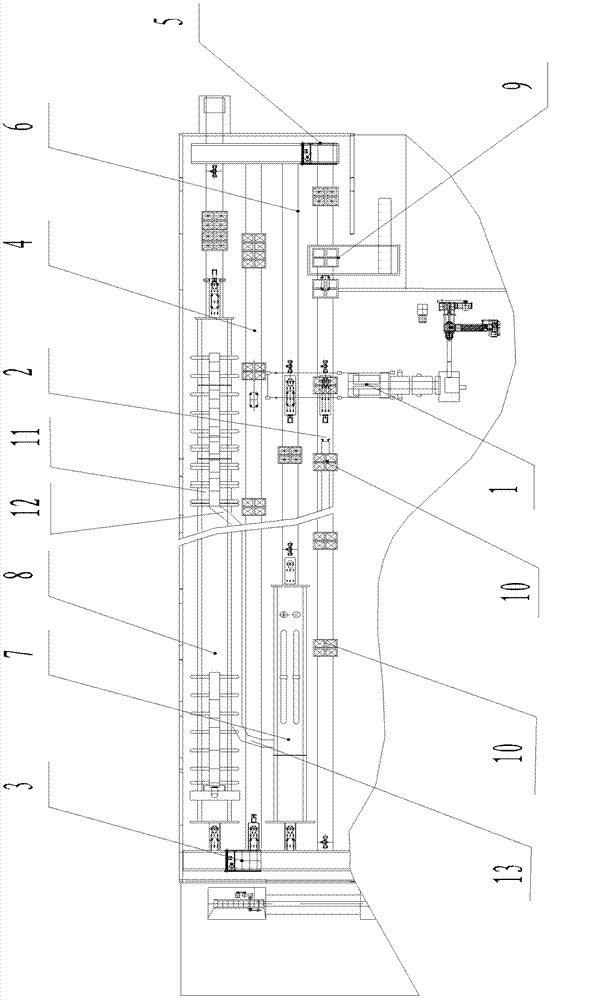

[0017] Attached below figure 1 An embodiment of the present invention is described.

[0018] The process of firing bricks by drying and stacking for many times first makes the bricks circulate in multiple auxiliary channels to naturally dry and reduce the moisture content of the bricks, then stacks the wet bricks on the naturally dehydrated bricks, and then sends them to the drying room for heating and drying. The method enables the bricks to be stacked until the space of the sintering kiln 11 is sufficient to accommodate the height. For example, when using clay to make bricks, due to the high moisture content and low strength of the formed bricks, generally only less than 6 layers are stacked in the direction of 115mm, and the stacking will cause the lower bricks to deform or even collapse. After adopting this technical scheme, the 6-layer brick adobe stacked for the first time is naturally dried and dehydrated, and the height of the circular stacking can finally reach 18 la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com