Water-saving clarification and purification system and process thereof

A purification system, water-saving technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor reaction effect, scattered process equipment and large area and other problems, to achieve the effect of good reaction effect, improved reaction effect, and reduced floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

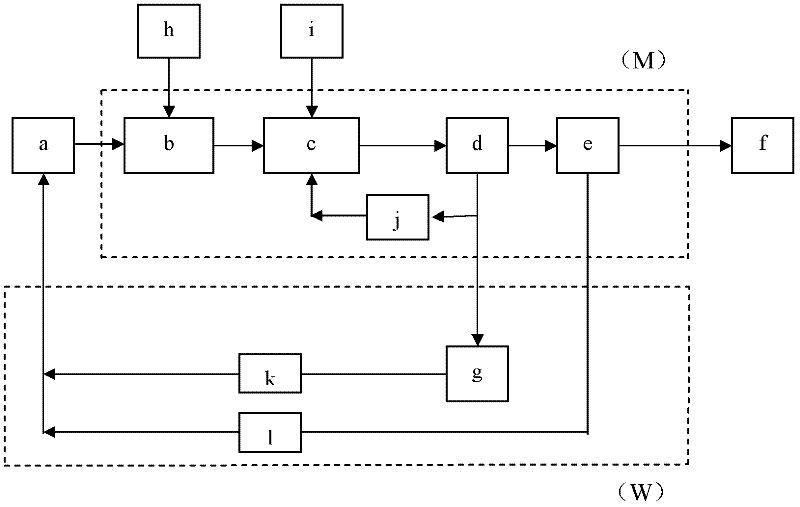

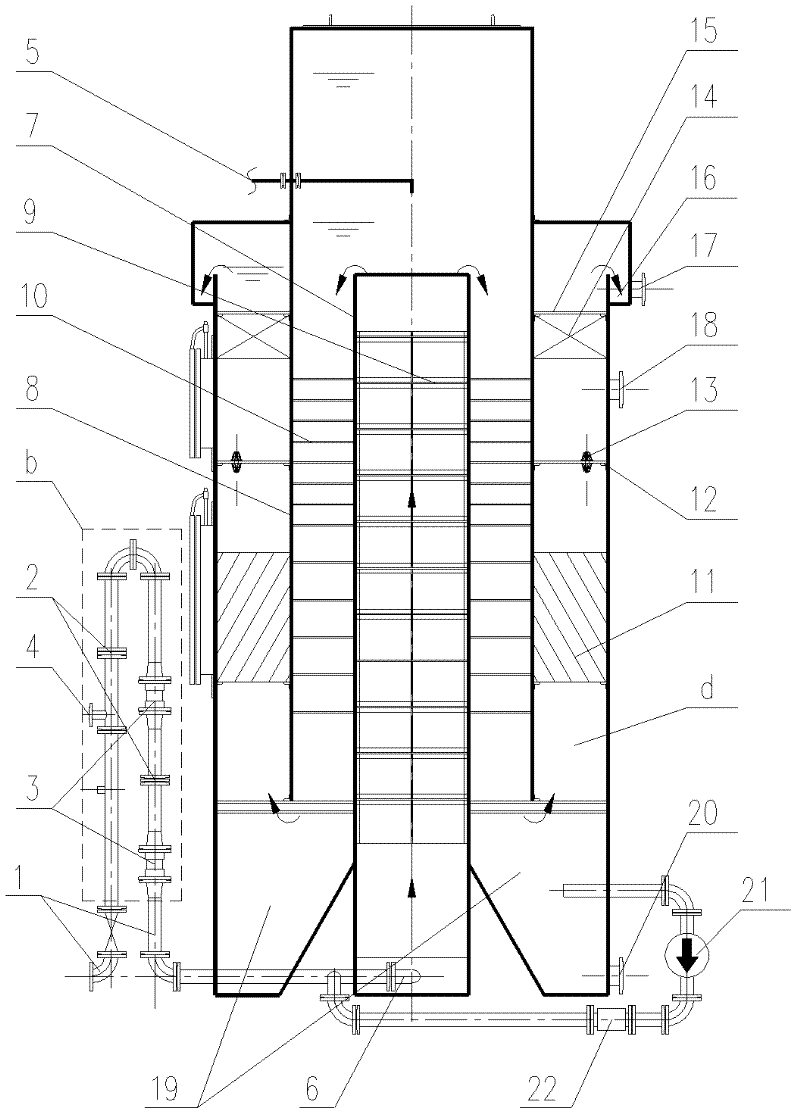

[0027] see figure 1 , the present invention includes a raw water tank a, a clean water tank f, and a multi-stage pipeline mixer b, a variable aperture fin flocculation reactor c, a sediment separator d, a filter e and mud that are arranged between the raw water tank a and the clean water tank f An integrated clarifier M composed of a slag reflux device j, and a sludge disposal system W connected to the integrated clarifier M, in which the raw water tank a, the multi-stage pipeline mixer b, and the variable aperture vane flocculation reactor c , sedimentation separator d, filter e and clear water tank f are connected in sequence, sedimentation separator d is also connected with variable aperture fin flocculation reactor c through sludge return device j, and multi-stage pipeline mixer b and variable aperture fin The sheet flocculation reactor c is also connected in turn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com