Flexible trolley switching system

A technology for switching systems and trolleys, which is applied in welding/cutting auxiliary equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of no public reporting of vehicle type switching equipment, and achieve simple and reliable driving methods, accurate positioning, and flexible methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

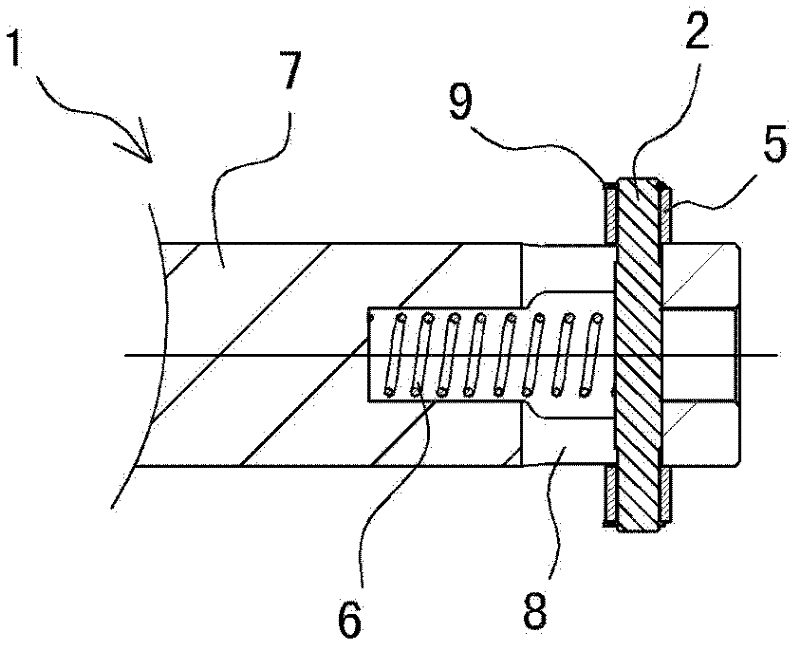

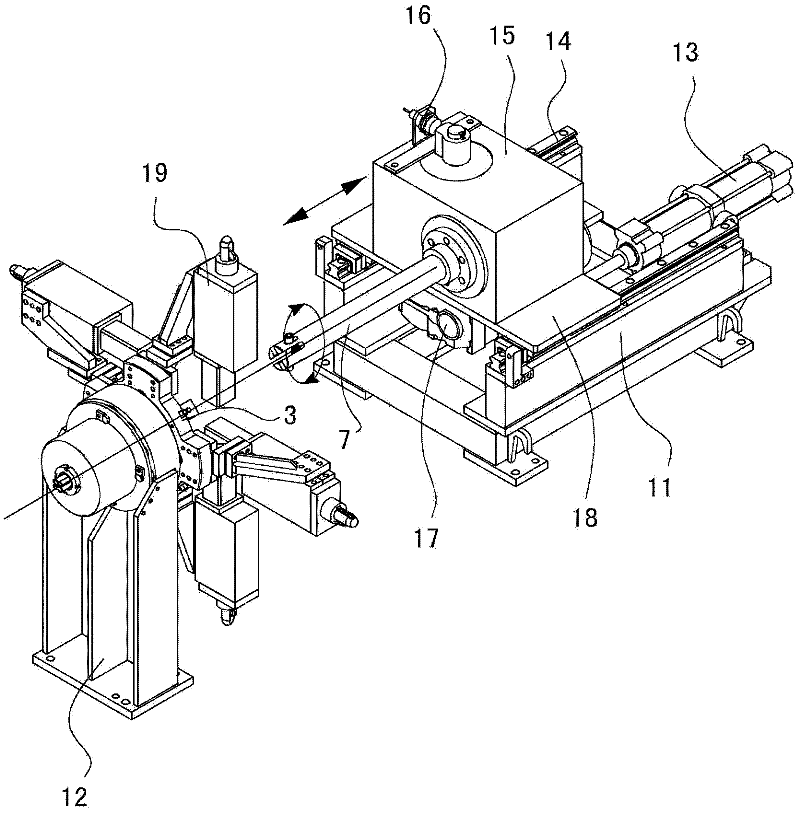

[0025] see figure 1 , figure 2 and image 3 , the structure of the flexible trolley switching system in this embodiment is set as:

[0026] A drive switching unit 1: having a rotatable and axially movable cylinder 7, at the front end of the cylinder 7, a dial shaft 2 is arranged radially through the cylinder 7;

[0027] A passive positioning unit 10: has a drum 3 that is on the same axis as the cylinder body 7 and can rotate, and an open shaft hole 4 is arranged on the front face of the drum 3 in cooperation with the dial shaft 2 to dial The shaft 2 is pushed into the opening dial shaft hole 4 to form the docking of the cylinder body 7 and the drum 3; the opening dial shaft holes 4 are set as multiple groups at different circumferential angles of the drum 3, and the dial shaft 2 can be selectively docked on In the opening shifting shaft holes 4 at different circumferential angle positions; the positioning systems of four different vehicle models are located on the peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com