Reaction kettle with flow slowing device

A technology of reaction kettle and kettle body, which is applied in the field of stabilizer production devices, can solve the problems of affecting the appearance and quality, slow discharging speed, uneven thickness of tablet pressing, etc., so as to ensure product performance and appearance, flow uniformity, and prevent roll wrapping. or uneven slicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

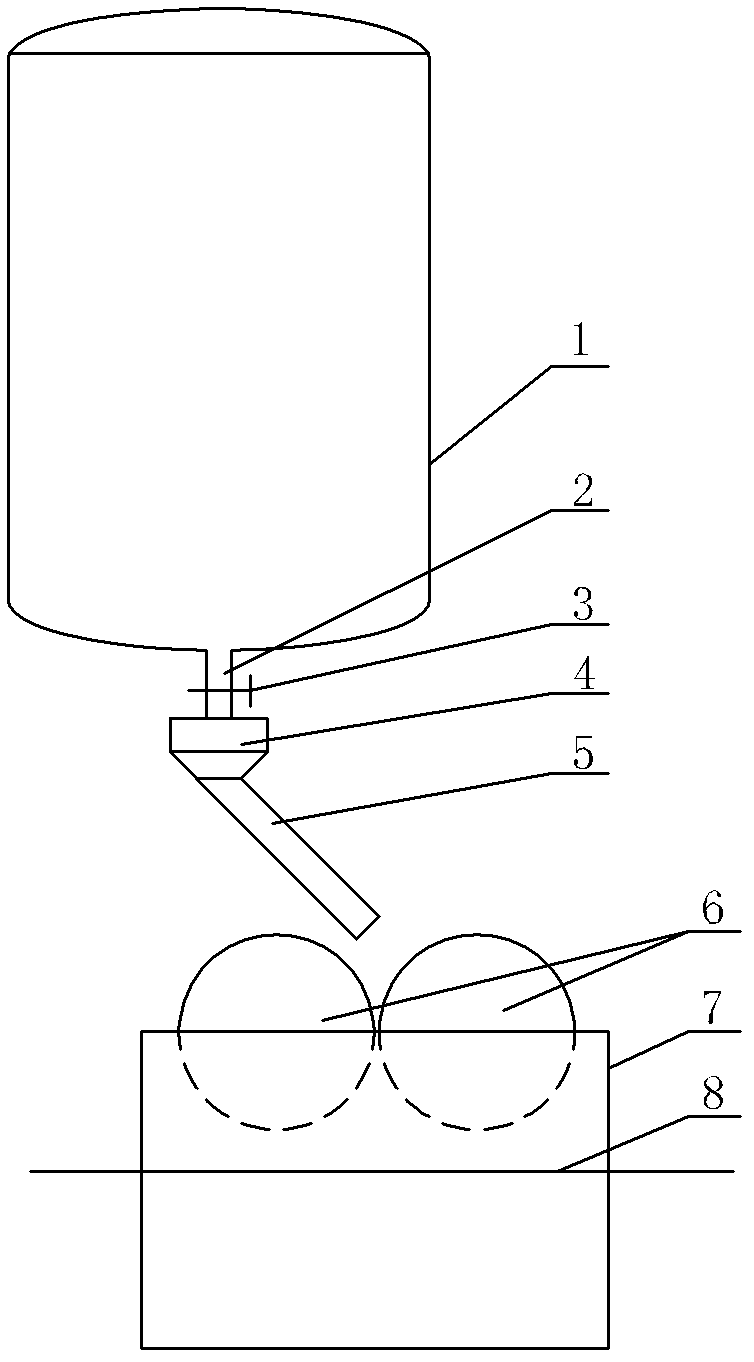

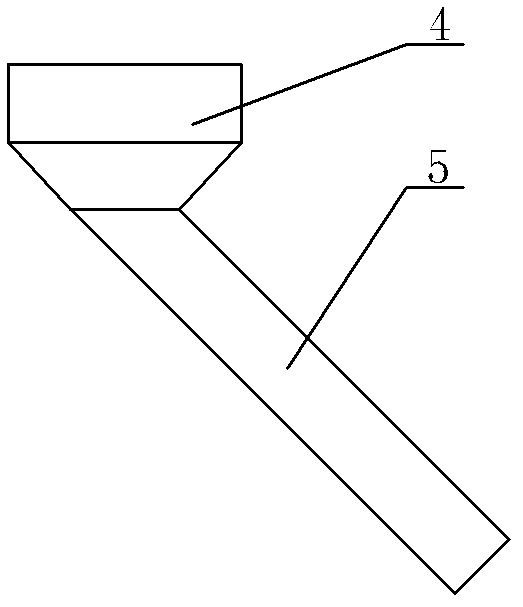

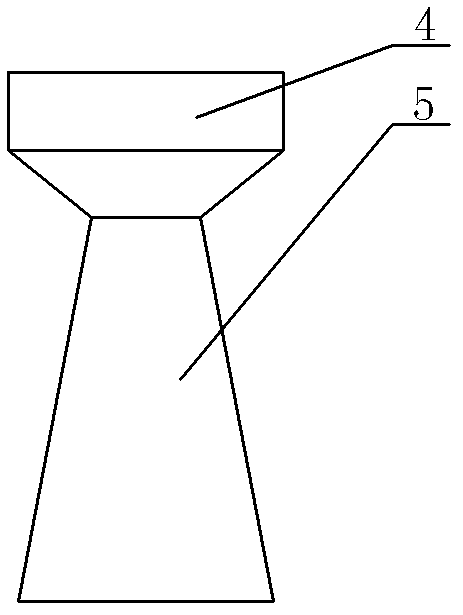

[0015] Such as Figure 1~3 As shown, the reaction kettle with a slow flow device includes a kettle body 1, a discharge valve 3 is installed at the discharge port 2 at the bottom of the kettle body 1, and a slow flow device is installed under the discharge port 2, and the slow flow device is controlled by the feed port 4 and the slow chute 5 that is narrow at the top and wide at the bottom are connected up and down to form, and feed port 4 is positioned at the just below discharge port 2, and the angle between slow chute 5 and horizontal plane is 45 °.

[0016] When in use, it is necessary to ensure that the end of the slow chute 5 corresponds to the position of the gap between the two squeeze rollers 6 in the slicer 7, so as to ensure that the liquid stabilizer enters the slicer 7 along the slow flow device. The liquid stabilizer produced in the reaction kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com