Multistage feeding method for cigarette making

A feeding method and cigarette technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problem that cannot keep up with the pace of high-quality, differentiated and individualized demand for raw materials of Chinese-style cigarette tobacco leaves, and cannot meet the flexible and changeable feeding process In order to reduce the risk of uneven feeding, balance water, and absorb sufficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

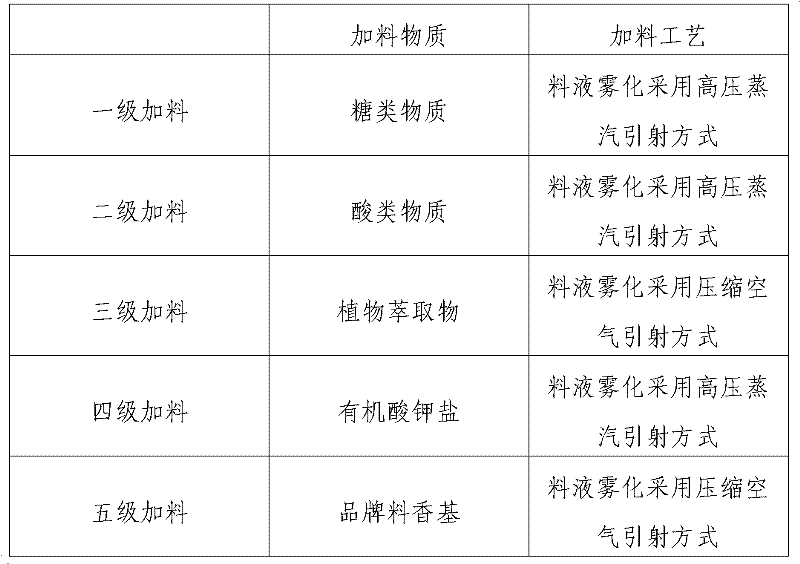

[0015] Hongyun Honghe Group Kunming Cigarette Factory performs multi-stage feeding treatment on the leaf module of Yunyan (soft treasure) brand cigarettes (see process figure 1 ), the feeding method is mainly based on the style characteristics of the brand cigarettes, and different types of feed liquids are designed in combination with the characteristics of the leaf group module, and the "multi-stage feeding" method is used to process the leaf group module. The quality and use value of the group modules are determined to meet the overall comprehensive quality of the cigarette. The feed liquid and feeding process applied by each stage of feeding are shown in Table 1:

[0016] Table 1

[0017]

[0018] After adding the ingredients according to the method of the present invention, the sensory quality evaluation is carried out. Compared with the traditional craft cigarettes, the cigarette aroma is increased, the aftertaste is more comfortable, and the "sweet and fragrant" sty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com