Method for improving planar orientation of cholesteric liquid crystal based on phase transition between smectic phase and cholesteric phase

A cholesteric liquid crystal, plane alignment technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., to achieve the effect of improving transmittance, improving order, and improving the utilization rate of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

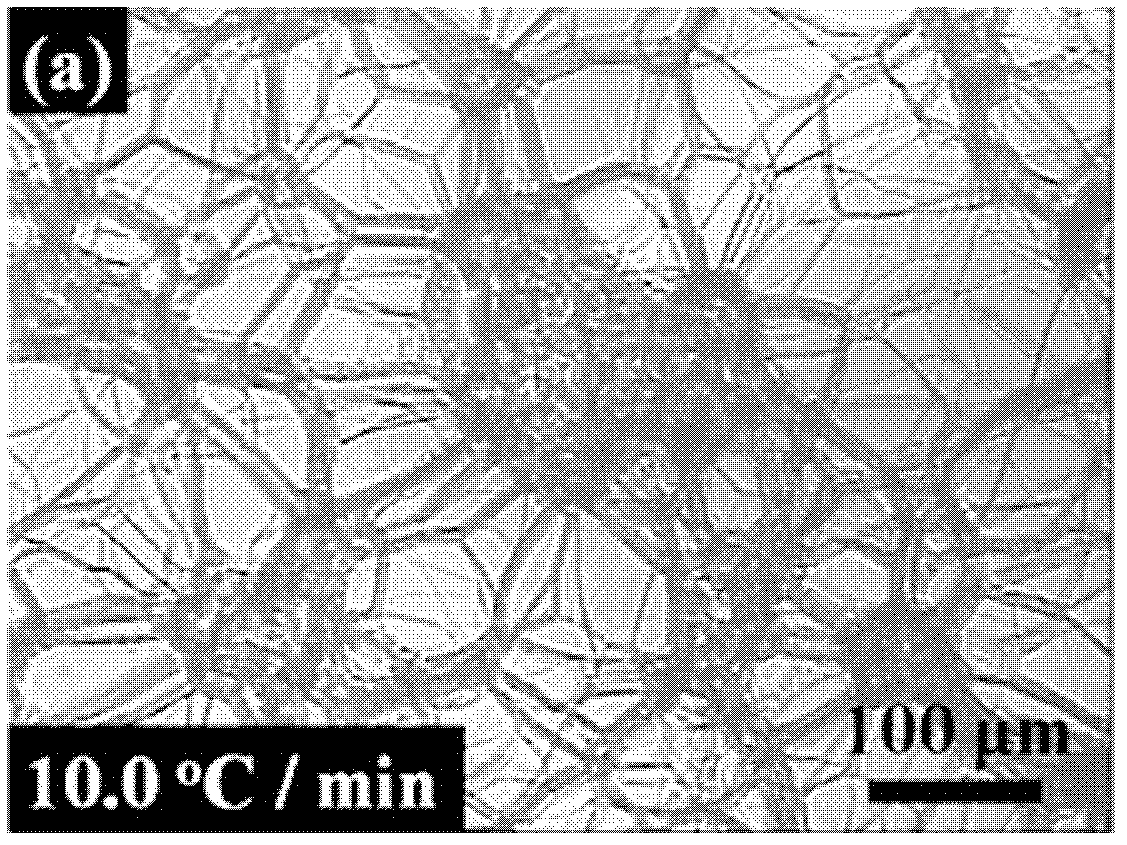

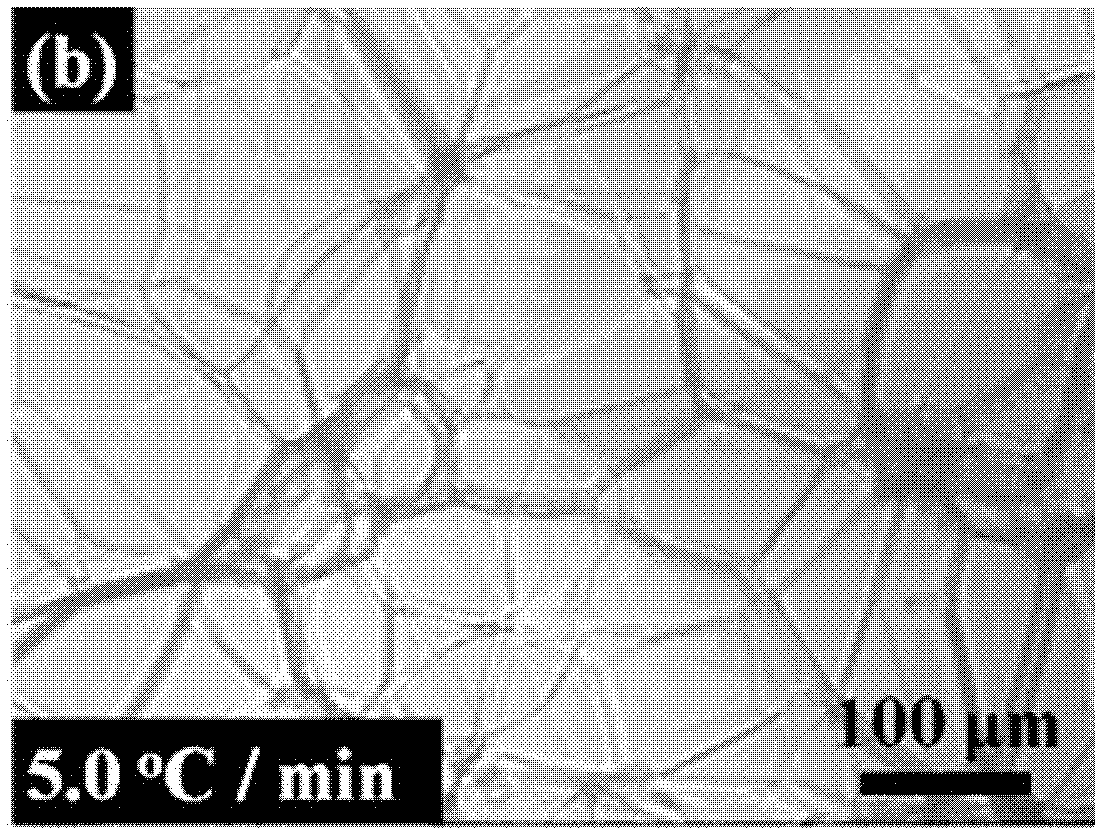

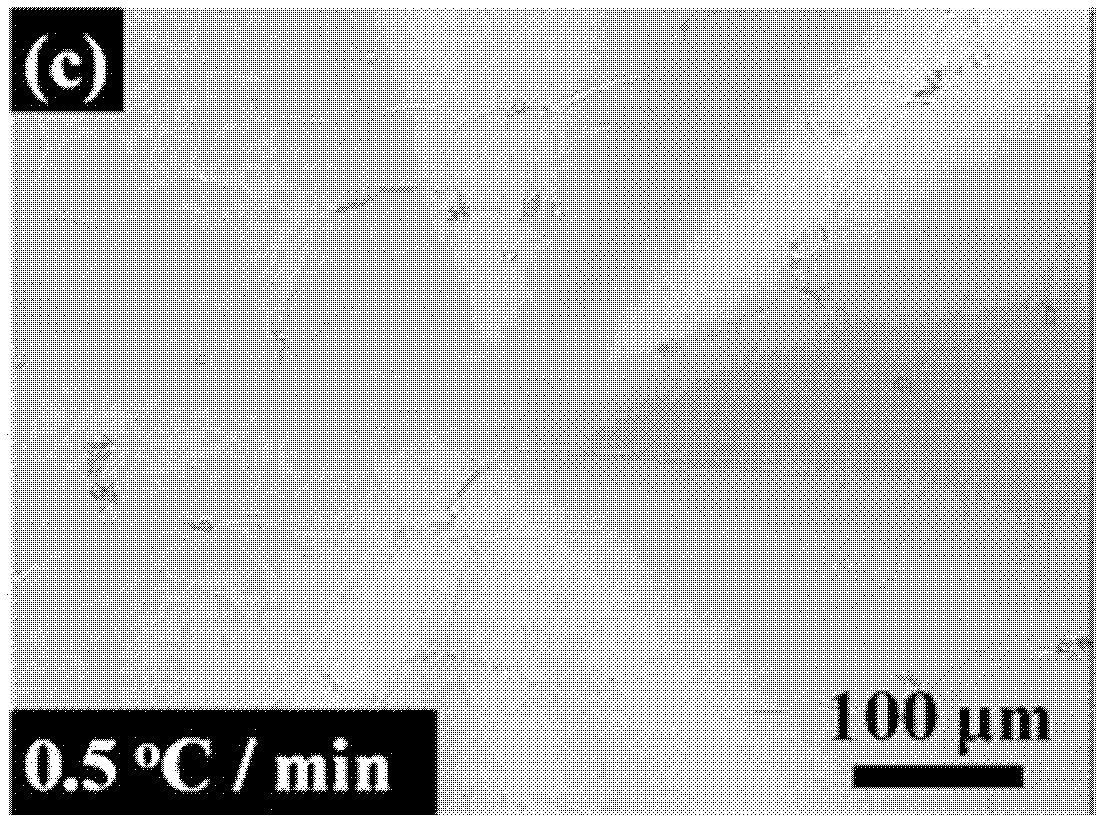

[0040] First, clean the glass to make a liquid crystal cell. Modulate the mixture (sample 1) of smectic liquid crystal 8CB / cholesteric liquid crystal 5*CBB / small molecule nematic liquid crystal SLC1717 / chiral additive S811 with smectic phase-cholesteric phase transition (sample 1). Percentage by weight is 27.7% / 44.3% / 18.0% / 10.0%, and its smectic phase-cholesteric phase transition temperature is 51.7 ℃ (T 1 ), the clearing point is 135.0°C. Pour sample 1 into a liquid crystal cell or between two layers of plastic films at the clearing point, and cool the sample of liquid crystal cell or film material to 45.0°C. The liquid crystal sample presents a focal conic texture of light scattering. Then from the smectic phase of the sample to the cholesteric phase temperature T of the sample at 10.0°C / min, 5.0°C / min, 0.5°C / min 2 (70.0°C), the texture change of the sample was tested by a polarizing microscope, and the transmittance change of the sample was tested by a UV spectrophotomete...

Embodiment 2

[0042] First, clean the glass to make a liquid crystal cell. Modulate the mixture (sample 1) of smectic liquid crystal 8CB / cholesteric liquid crystal 5*CBB / small molecule nematic liquid crystal SLC1717 / chiral additive S811 with smectic phase-cholesteric phase transition (sample 1). Percentage by weight is 27.7% / 44.3% / 18.0% / 10.0%, and the phase transition temperature of its occurrence smectic phase-cholesteric phase is 51.7 ℃ (T 1 ), the clearing point is 135.0°C. At the clearing point, pour sample 1 into a liquid crystal cell or between two layers of plastic films, and cool the sample of liquid crystal cell or film material to 45°C. The liquid crystal sample presents a smectic phase, which is a focal conic texture of light scattering. Then the temperature is raised from the smectic phase of the sample to the smectic phase-cholesteric phase transition temperature T of the sample at a rate of 20.0 °C / min. 1 , and then kept at the smectic phase-cholesteric phase transition temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com