Load test device for large-power frequency converter adopting front active end

A technology of load test and frequency converter, which is applied in the field of frequency converter, can solve the problems of many intermediate links, complex connection, large energy loss of mechanical parts, etc., and achieve the effect of less auxiliary equipment, simple connection and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

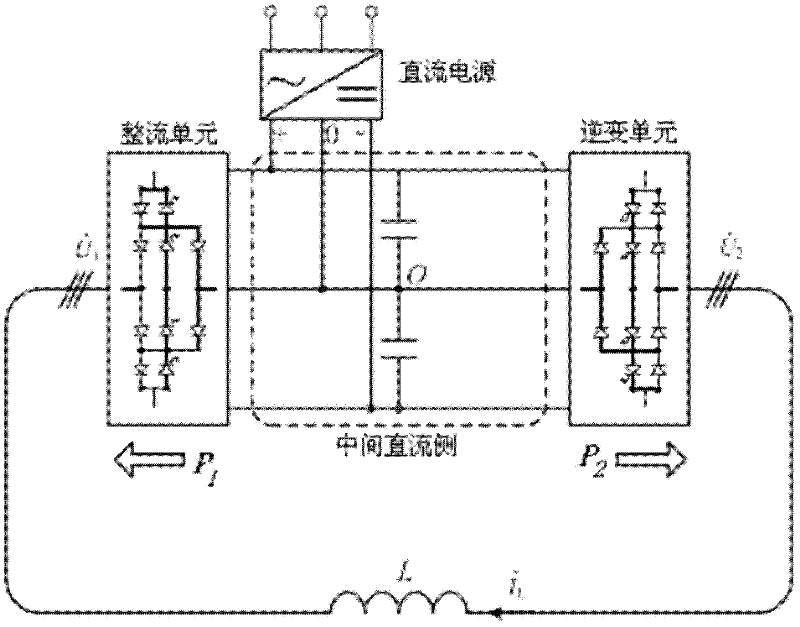

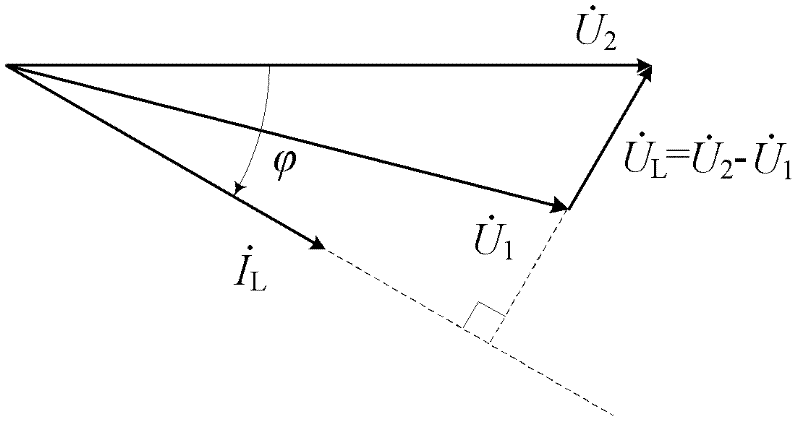

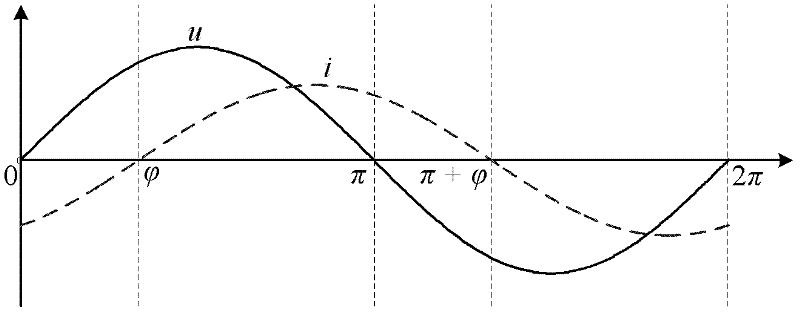

[0022] A high-power inverter load test device adopting an active front end realizes the load performance test function of the AC-DC-AC structure high-power inverter. The voltage and power factor output by the frequency converter are flexible and adjustable, and can simulate the working conditions of the load motor in four quadrants. The topology of the frequency converter to be tested can be a two-level or multi-level structure, and the power device used in the frequency converter can be IGCT or IGBT. Such as figure 1 As shown, the high-power inverter load test device using the active front end includes an inverter, a DC power supply and a reactor. In this embodiment, the inverter is a three-level midpoint voltage clamping structure. , the intermediate DC side, and the inverter unit. A reactor with a small capacity is connected between the rectif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com