Hydraulic early warning method and device for concrete structure

A technology of concrete structure and early warning device, applied in the direction of optical testing flaws/defects, etc., can solve the problems of strain gauge damage, high technical cost, disorder, etc., and achieve the effects of no signal interference, not easy to damage, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

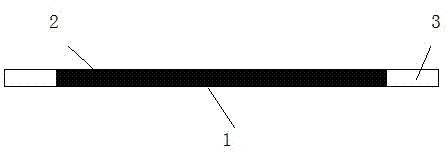

[0023] Such as figure 1 As shown, the early warning tube that meets the material requirements is used, after the colored liquid mixed with fluorescent powder is poured in, the two ends are inflated and pressurized to a pressure that can fully make the liquid spray out, and the seal is sealed. In this way, the early warning tube is ready, and then some scratches are added on the surface of the early warning tube. When the early warning tube is buried in the concrete, the friction force can be increased to further prevent slippage between the concrete and the early warning tube. In addition, the early warning pipe should not be too thick, otherwise it will affect the structural bearing capacity. The early-warning pipe should be buried in a position that is more likely to be damaged. For example, according to the characteristics of compression bending damage, the lower part of the beam bears the largest tensile force when the beam is bent, and the concrete usually cracks from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com