Method for determining content of calcium carbonate in cigarette paper

A technology of calcium carbonate and cigarette paper, applied in the direction of color/spectral property measurement, etc., can solve problems such as unsuccessful reports, and achieve the effects of good application prospects, fast analysis speed, high accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Experimental principle, materials and methods

[0030] 1.1 Experimental principle

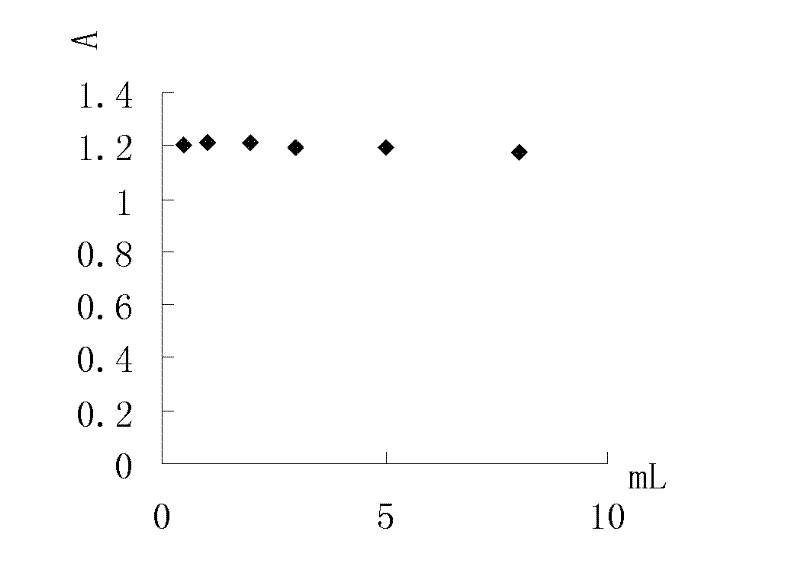

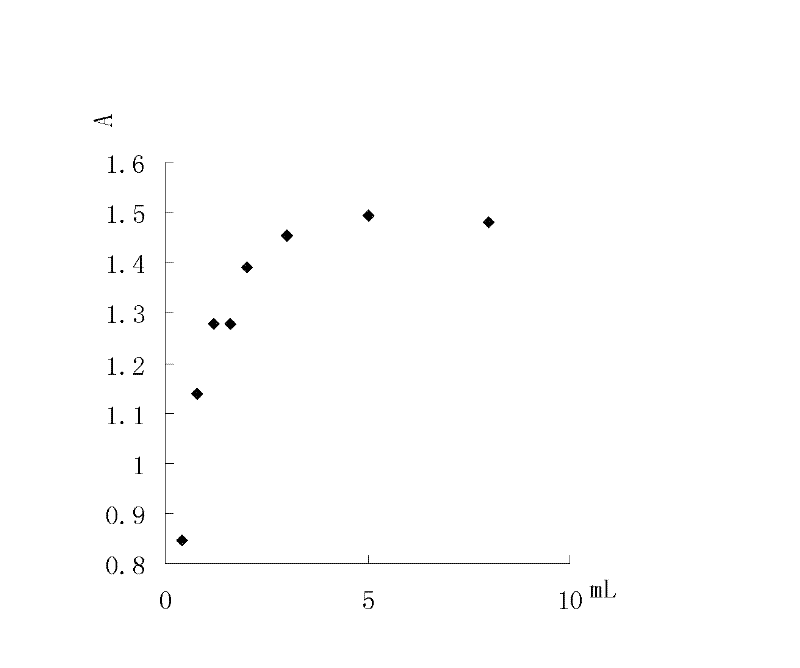

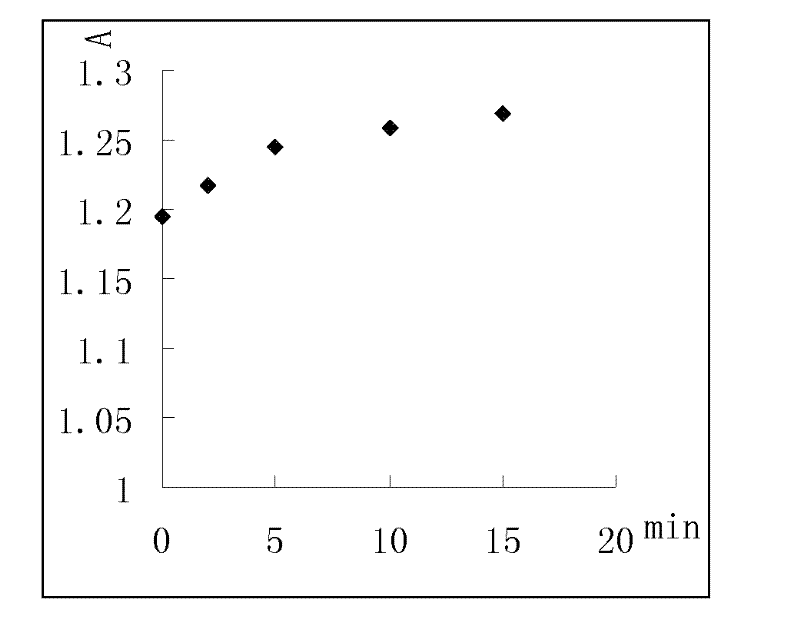

[0031] Cigarette paper samples were reacted with a known exact amount of excess HCl solution, and the remaining H+ was detected spectrophotometrically. The acid content is directly proportional to the concentration of the color product and can be measured at 352nm. Calcium carbonate content (calculated as CaO) of cigarette paper can be deduced from the acid content.

[0032] 1.2 Materials and Instruments

[0033] Potassium iodate (AR, Shanghai Runjie Chemical Reagent Co., Ltd.); Potassium iodide (AR, Shanghai Chemical Reagent Co., Ltd.), hydrochloric acid (AR, Xilong Chemical Plant, Shantou City, Guangdong); calcium carbonate (working reference reagent (capacity), Tongji Institute of trace elements); distilled water with carbon dioxide removed (self-made); 4 cigarette paper samples are products of Yunnan Hongta Lanying Paper Co., Ltd.

[0034] JA5002 balance (sensitivity: 0.01g, S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com