Pigment sheet and manufacturing method thereof

A manufacturing method and technology of pigment flakes, which are applied in the field of pigments, can solve the problems of easy destruction of embossed information, poor display effect of embossed information, anti-counterfeiting and reduced decorative effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

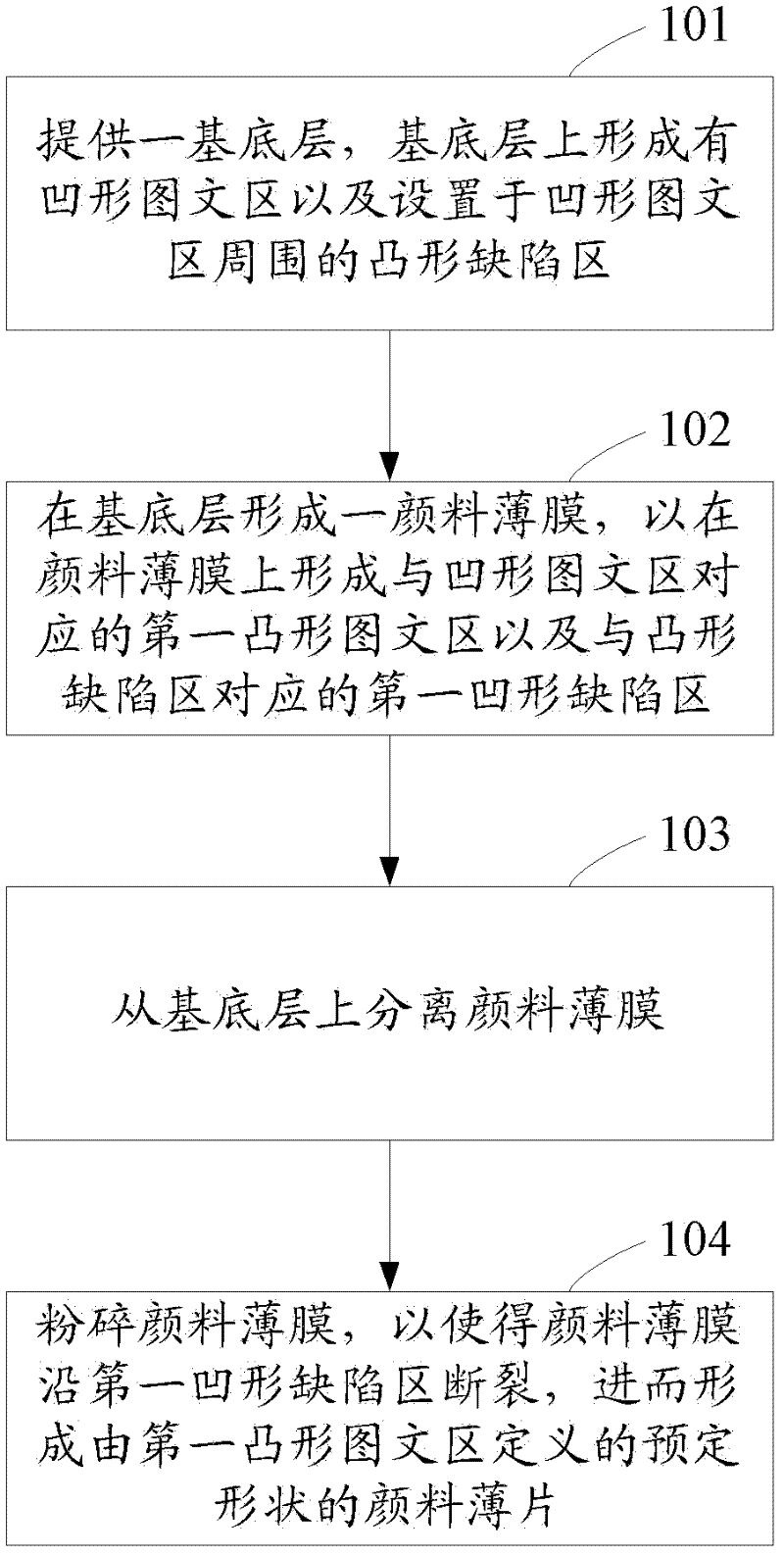

[0026] see first figure 1 , figure 1 It is a flowchart of a preferred embodiment of a method for manufacturing pigment flakes of the present invention. Such as figure 1 Shown, the manufacture method of a kind of pigment flake disclosed by the present invention comprises the following steps:

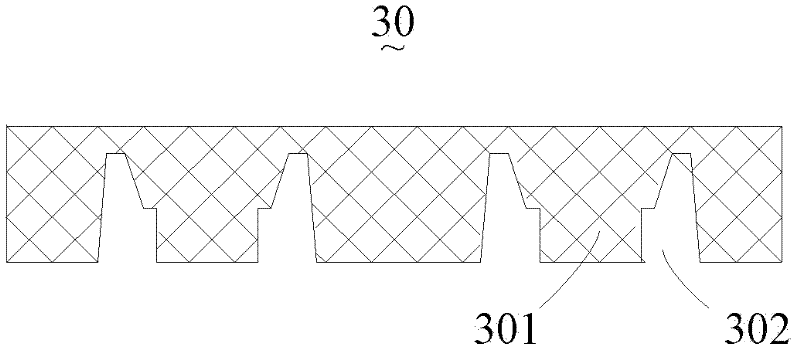

[0027] Step 101 : providing a base layer, on which a concave image-text area and a convex defect area disposed around the concave image-text area are formed.

[0028] Step 102: forming a pigment film on the base layer, so as to form a first convex graphic area corresponding to the concave graphic area and a first concave defect area corresponding to the convex defect area on the pigment film.

[0029] Step 103: separating the pigment film from the base layer.

[0030] Step 104: Pulverizing the pigment film, so that the pigment film breaks along the first concave defect area, thereby forming a predetermined shape of the pigment flake defined by the first convex pattern area.

[0031] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com