Optically active tryptamine derivative and synthetic method and application thereof

An optically active and synthetic method technology, applied in the field of optically active tryptamine derivatives and their synthesis, can solve the problems of high cost, low yield, complicated operation and the like, and achieve high selectivity, high yield, simple and safe operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049]

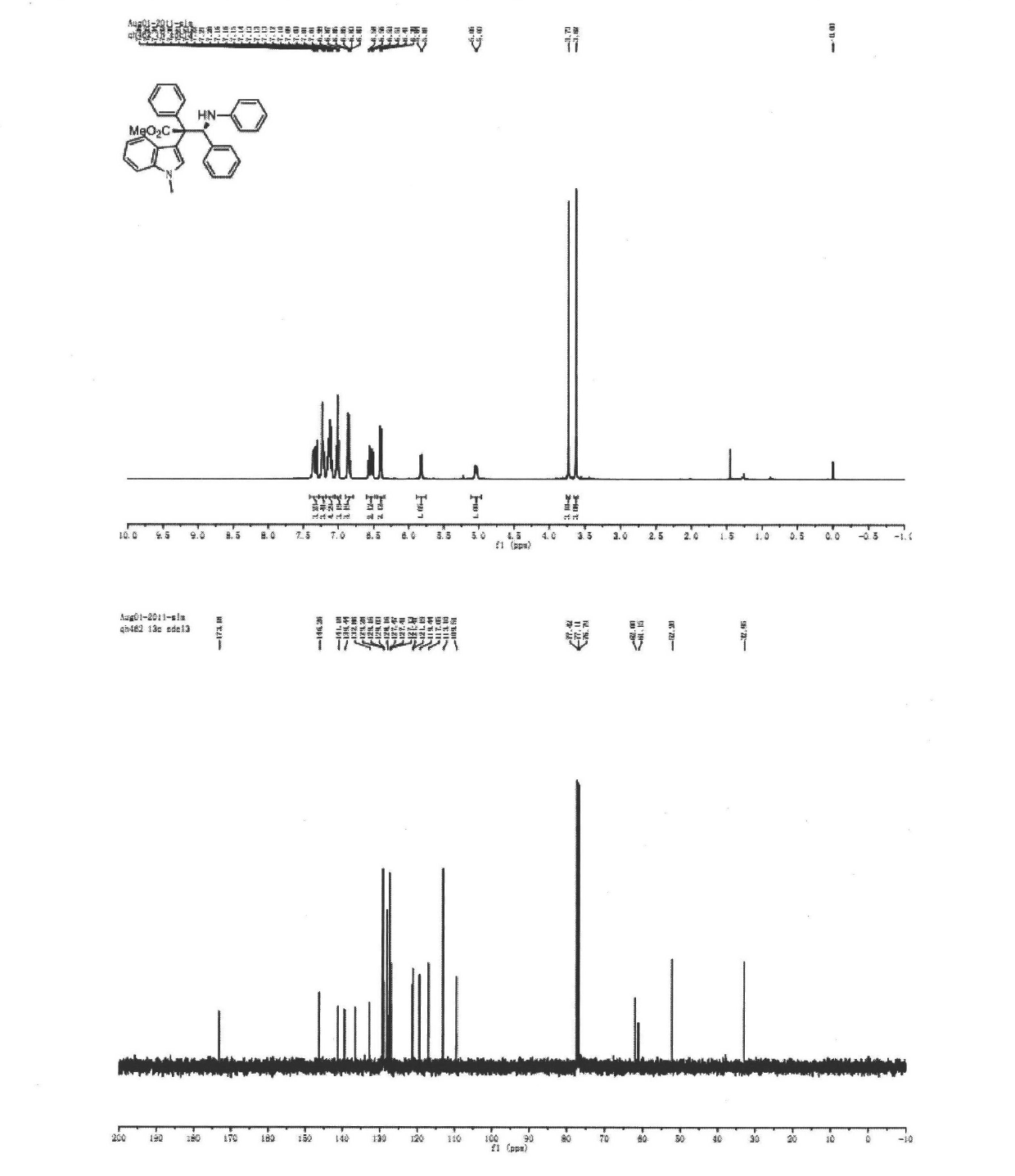

[0050] N-methylindole (0.3mmol), N-benzylidene aniline (0.3mmol), Rh 2 (OAc) 4 (0.0025mmol), chiral small molecule catalyst PPA (0.005mmol) and Molecular sieves (0.1g) were dissolved in toluene (2ml), then, methyl phenyldiazoacetate (0.25mmol,) dissolved in toluene (2.0ml) was added dropwise in the reaction system in 2 hours, and the reaction system was At -10°C, after the dropwise addition, the mixture was stirred for 12 hours, and the solvent was removed by rotary evaporation under reduced pressure to obtain a crude product, the structure of which was shown in formula (2-1). The crude product was subjected to column chromatography (ethyl acetate:petroleum ether=1:100~1:40) to obtain a pure product. Yield 94%, dr > 20:1, ee% = 97%. nuclear magnetic resonance 1 H NMR, 13 C NMR spectrum as figure 1 As shown, the product 4a 1 H NMR (400MHz, CDCl 3 )δ (ppm) 3.65 (s, 3H), 3.78 (s, 3H), 5.06 (br, 1H), 5.79 (d, J = 8.2Hz, 1H), 6.39 (d, J = 8.0Hz, 2H), 6.53(d, J=...

Embodiment 2

[0052]

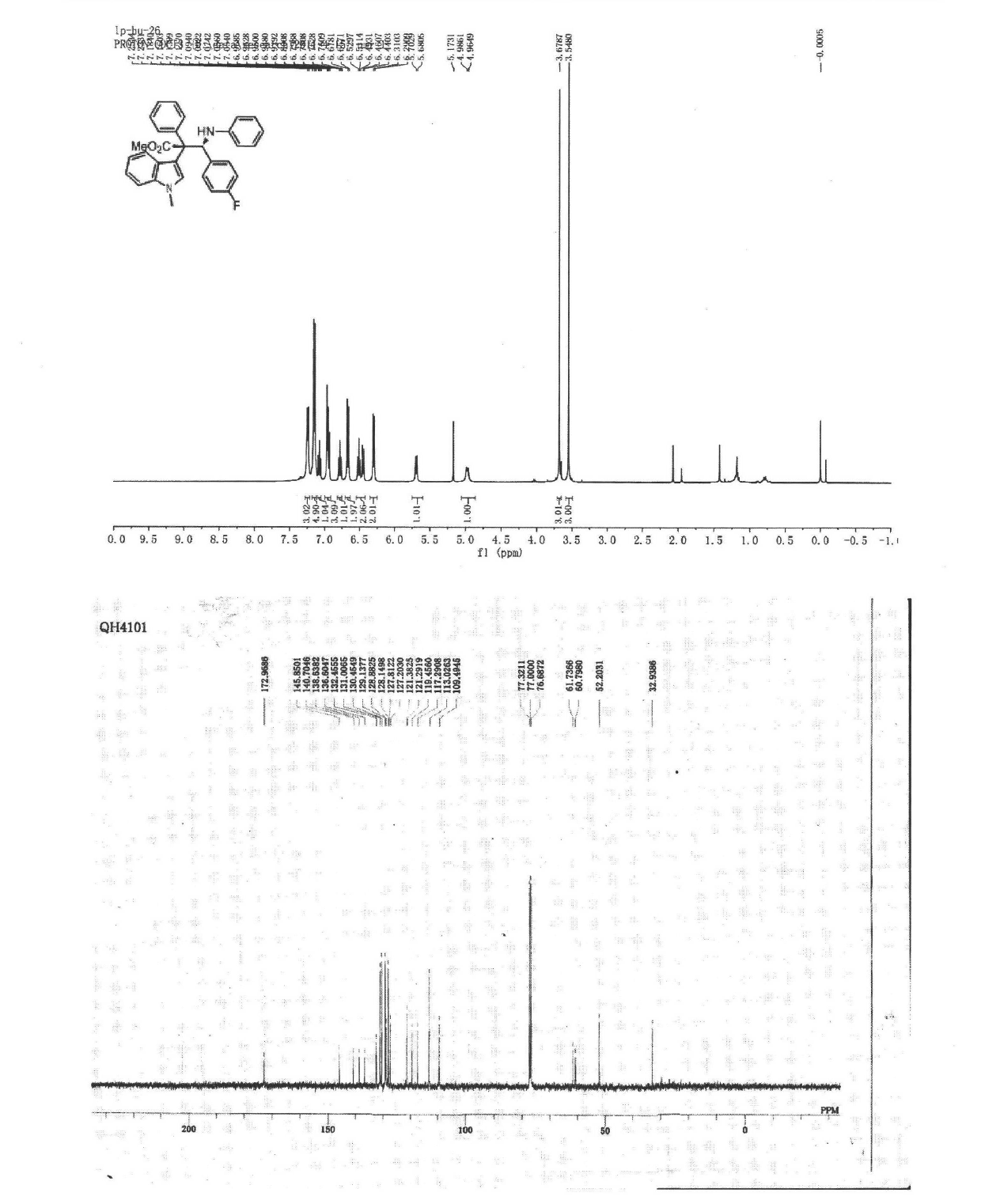

[0053] N-methylindole (0.3mmol), N-(4-bromobenzylidene) aniline (0.3mmol), Rh 2 (OAc) 4 (0.0025mmol), chiral small molecule catalyst PPA (0.005mmol) and Molecular sieves (0.1g) were dissolved in toluene (2ml), then, methyl phenyldiazoacetate (0.25mmol,) dissolved in toluene (2.0ml) was added dropwise in the reaction system in 2 hours, and the reaction system was At -10°C, after the dropwise addition was completed, the mixture was stirred for 12 hours, and the solvent was removed by rotary evaporation under reduced pressure to obtain a crude product, the structure of which was shown in formula (2-2). The crude product was subjected to column chromatography (ethyl acetate:petroleum ether=1:100~1:40) to obtain a pure product. Yield 93%, dr > 20:1, ee% = 99%. nuclear magnetic resonance 1 H NMR, 13 C NMR spectrum as figure 2 As shown, the product 4b 1 H NMR (400MHz, CDCl 3 )δ(ppm) 3.55(s, 3H), 3.68(s, 3H), 4.98(d, J=8.5Hz, 1H), 5.69(d, J=8.9Hz, 1H), 6.30(d, J=...

Embodiment 3

[0055]

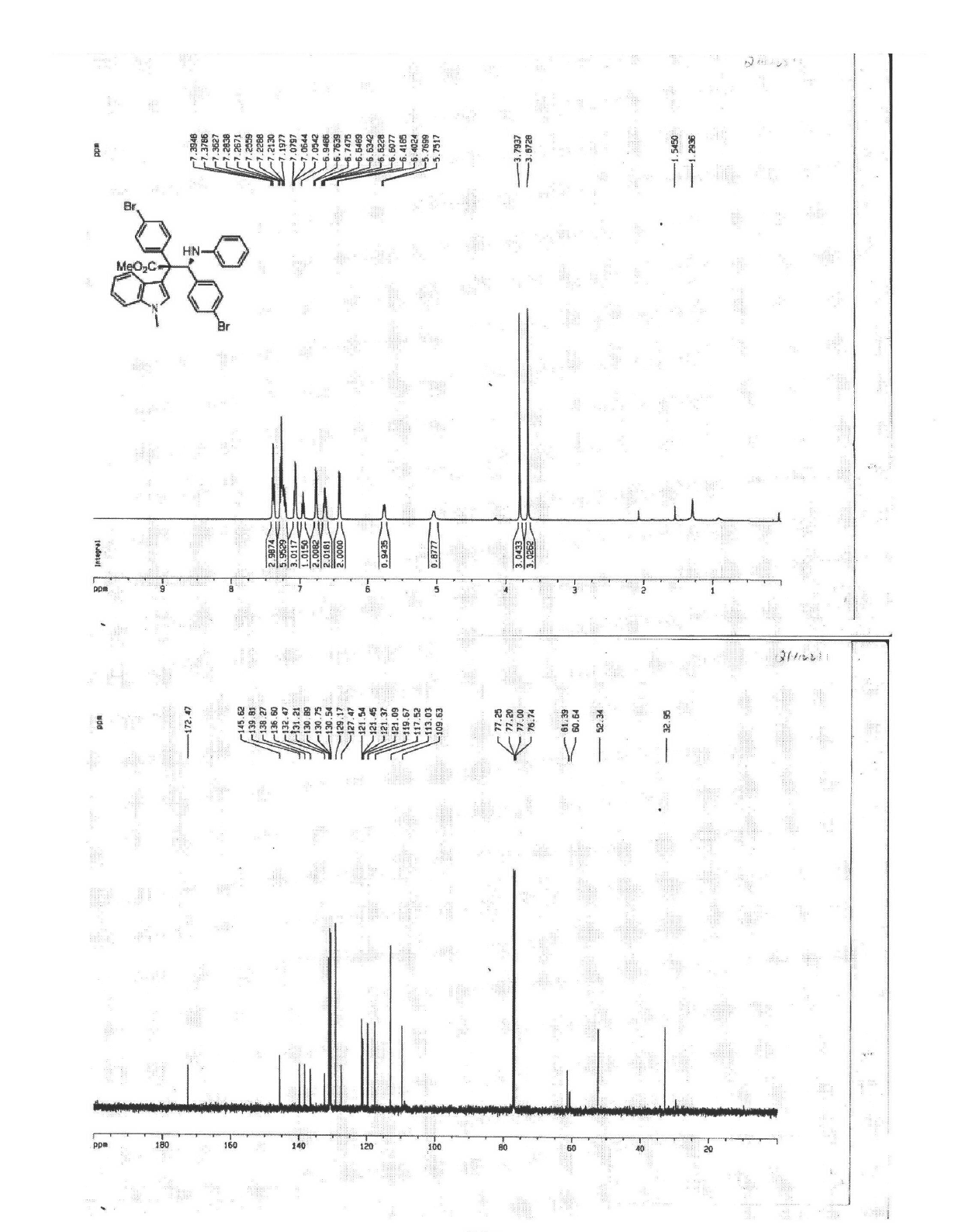

[0056] N-methylindole (0.3mmol), N-(4-bromobenzylidene) aniline (0.3mmol), Rh 2 (OAc) 4 (0.0025mmol), chiral small molecule catalyst PPA (0.005mmol) and Molecular sieves (0.1g) were dissolved in toluene (2ml), then, 4-bromophenyldiazoacetic acid methyl ester (0.25mmol,) dissolved in toluene (2.0ml) was added dropwise in the reaction system within 2 hours, The reaction system was kept at -10°C. After the dropwise addition was completed, it was stirred for 12 hours, and the solvent was removed by rotary evaporation under reduced pressure to obtain a crude product, the structure of which was shown in formula (2-3). The crude product was subjected to column chromatography (ethyl acetate:petroleum ether=1:100~1:40) to obtain a pure product. Yield 85%, dr > 20:1, ee% = 91%. nuclear magnetic resonance 1 H NMR, 13 C NMR spectrum as image 3 As shown, the product 4c 1 H NMR (500MHz, CDCl 3 )δ(ppm) 3.67(s, 3H), 3.79(s, 3H), 5.05(br, 1H), 5.76(d, J=7.3Hz, 1H), 6.41(d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com