Submersible waterpower rotation flow plug aeration machine

A technology of hydraulic rotation and aerator, applied in the field of aerator, can solve the problems of complex structure, inflexibility, low efficiency, etc., and achieve the effect of improving the aeration range, simple structure and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

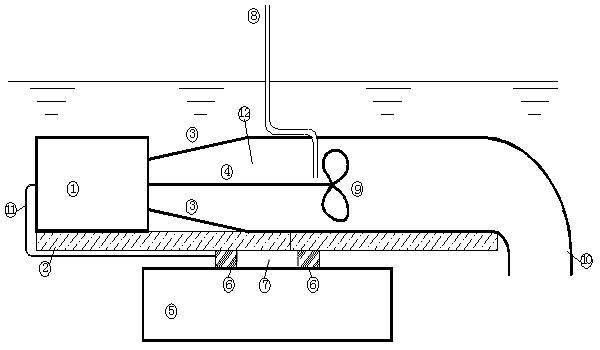

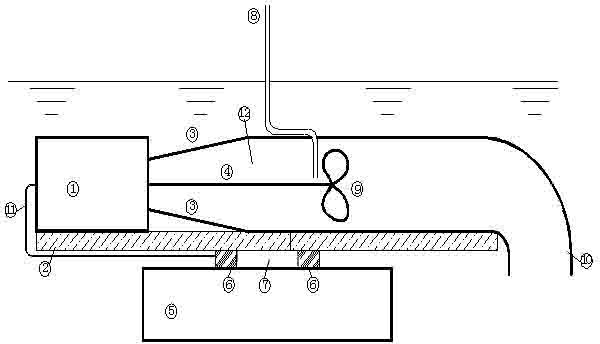

[0011] Such as figure 1 As shown, the submersible hydraulic rotary plug-flow aerator includes a motor 1 and a diversion elbow 10, the motor 1 is connected to the bidirectional impeller 9 via the rotating shaft 4, the motor 1 drives the bidirectional impeller 9 to rotate, and the bidirectional impeller 9 stretches into the guide elbow 10 on one side, a section of guide elbow 10 is a grille 3 between the two-way impeller 10 and the motor 1, and a suction pipe 8 is arranged near the two-way impeller 9, and the The other end of the suction pipe 8 protrudes from the water surface, and the space surrounded by the grid 3, the motor 1 and the diversion elbow 10 forms a mixing chamber 12, and the tray 2 is arranged below the motor 1 and the diversion elbow 10, The tray 2 is connected to the fixed base 5 through the rotating bearing 7, and the conductive slip ring 6 is set on the rotating bearing 7, and the conductive slip ring 6 is located between the tray 2 and the fixed base 5. Moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com