Method for manufacturing and installing inclined curved side port

An installation method and technology of side doors, which are applied in ship construction, transportation and packaging, and ship parts, etc., can solve the problems of troublesome installation in the dock, difficult to quickly install, lack of etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

[0024] see first figure 2 , the method for manufacturing and installing an inclined curvature linear side door of the present invention comprises the following steps:

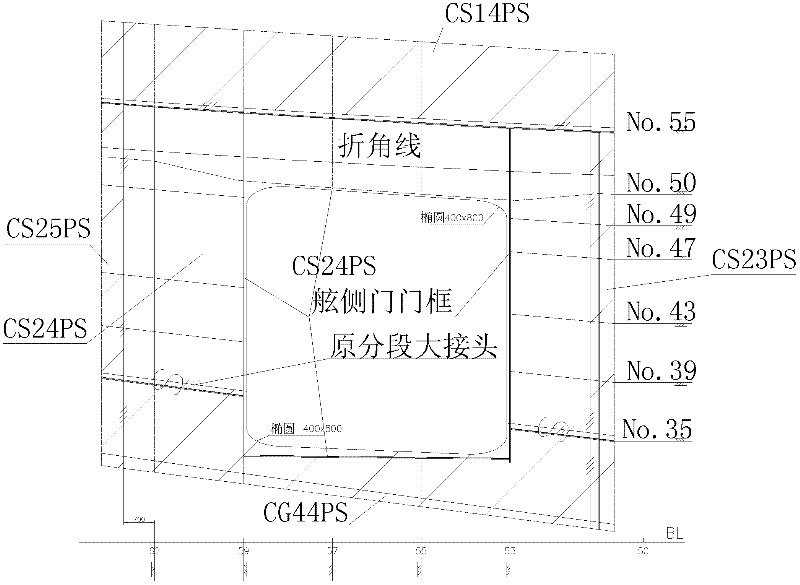

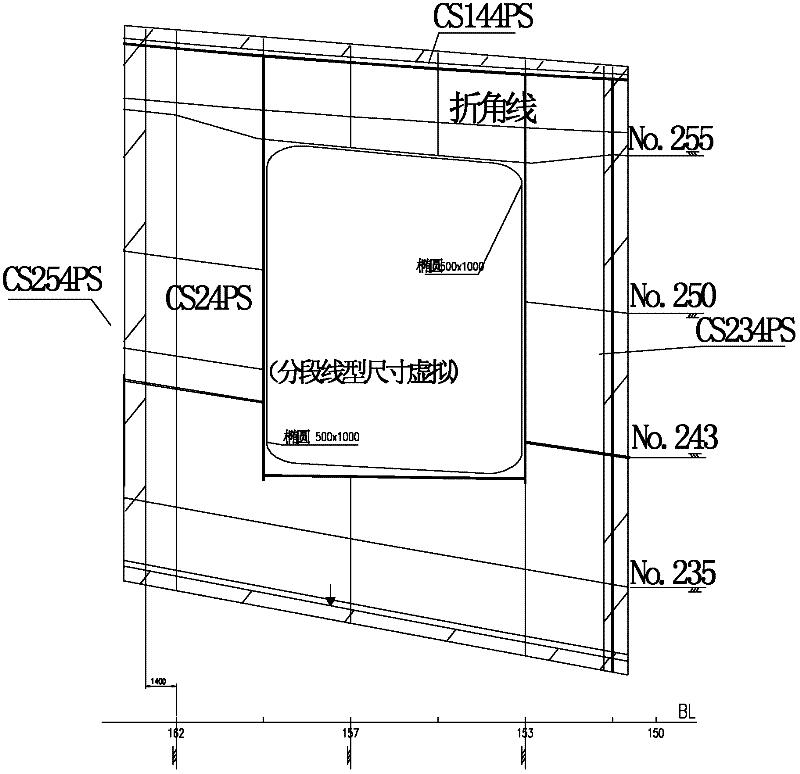

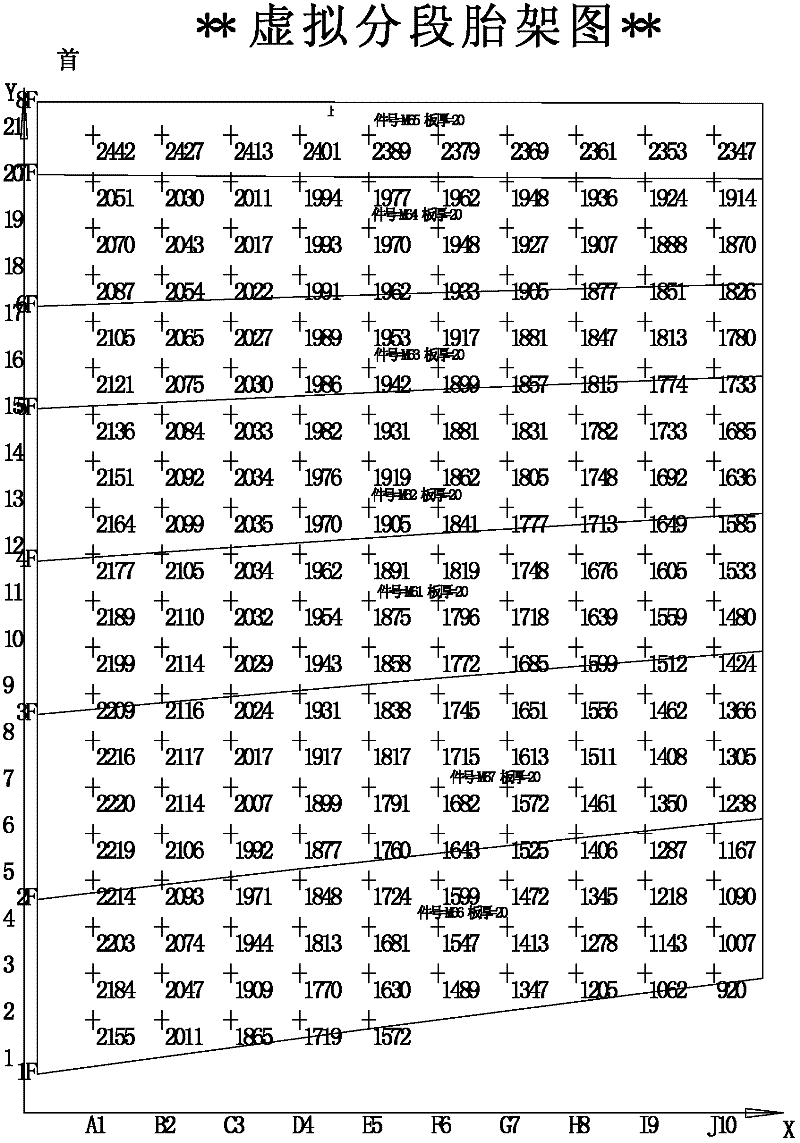

[0025] 1) According to the actual situation of the curvature of the line that the side door is manufactured and installed in the side area of the hull, re-divide into sections so that the new section includes the entire side door, and name it CS24APS section, such as figure 2 Shown: In this embodiment, the CS24APS section is a part of the structure of the CG44PS section divided into the original CS24APS section, and the side door embedded in the middle of the section CG44PS and CS24APS section is completely included in the CS24APS section In the section, and taking the center line of the side door as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com