Elastic device for front suspension for heavy articulated dump truck

An elastic device and articulated technology, applied in the direction of suspension, elastic suspension, vehicle parts, etc., can solve the problems of serious interference, large installation error, troublesome maintenance, etc., and achieve excellent elastic performance and shock absorption performance, easy to use and maintain Low cost and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

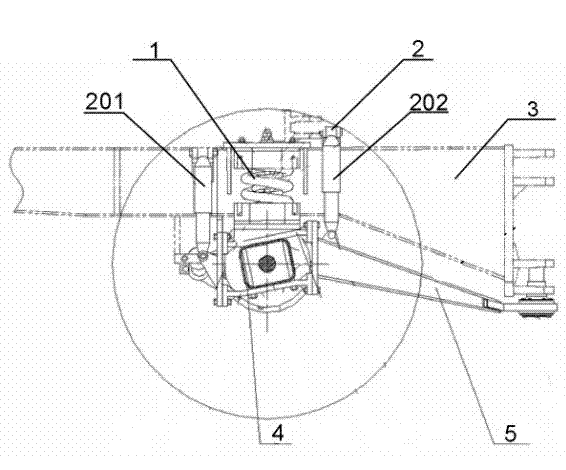

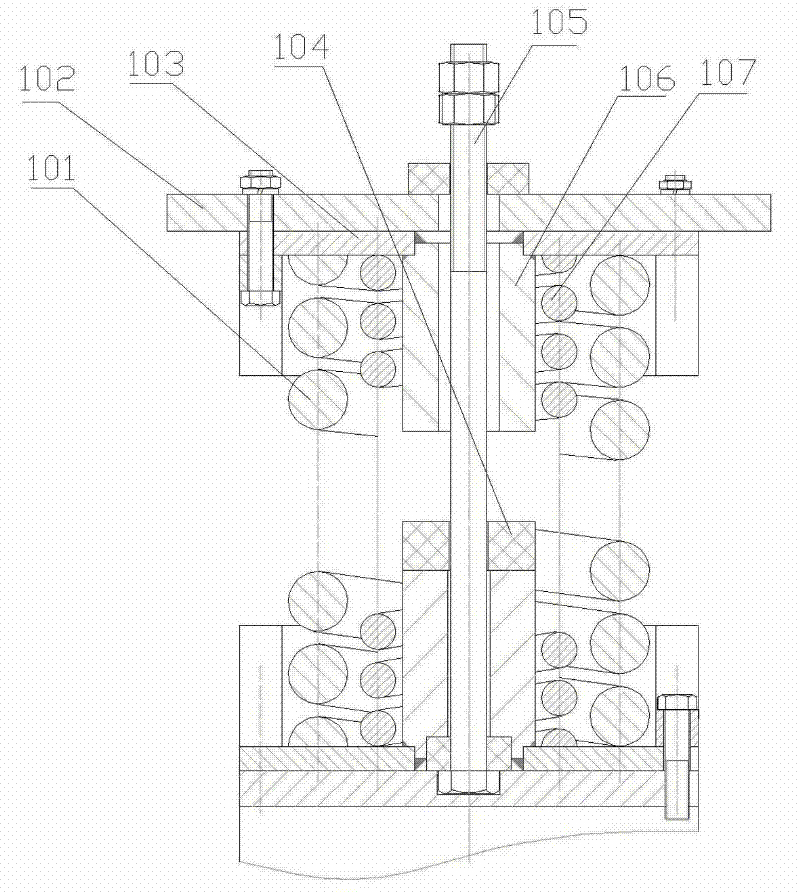

[0018] As shown in the figure, an elastic device for the front suspension of a heavy-duty articulated dump truck is arranged between the vehicle frame 3 and the axle 4, and is mainly composed of a double coil spring assembly 1 and a shock absorbing mechanism 2. The coil spring assembly 1 is provided with two groups and is arranged on both sides of the vehicle axle 4 respectively, the lower end of the double coil spring assembly 1 is connected with the vehicle axle 4, and its upper end is connected with the vehicle frame 3, and the double coil spring assembly 1 on each side is It is composed of an outer coil spring 101, a spring bracket 102, a support outer sleeve 103, a support inner sleeve 106 and an inner coil spring 107. The outer coil spring 101 is sleeved outside the inner coil spring 107 and is set together with the inner coil spring Between the support inner sleeve 106 and the support outer sleeve 103, wherein the rotation direction of the outer coil spring 101 and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com