Making process of wind-power blade main model

A wind power blade and manufacturing process technology, which is applied in the field of wind power blade forming, can solve the problems of many small square tubes of welded metal, too high staff quality requirements, long production cycle and other problems, so as to reduce production costs, have strong operability, and facilitate The effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

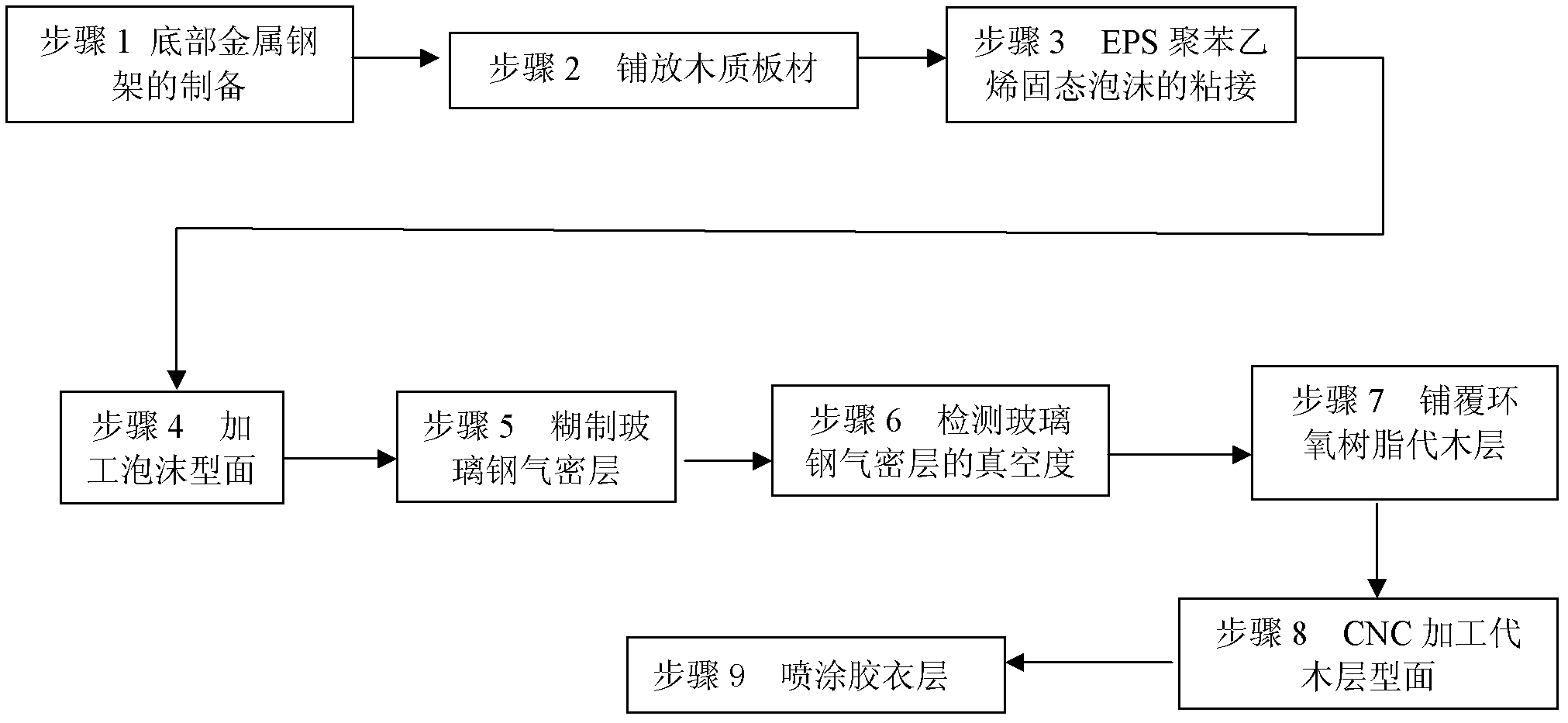

[0029] Such as figure 1 As shown, the manufacturing process of the wind power blade master model of the present invention includes the following steps:

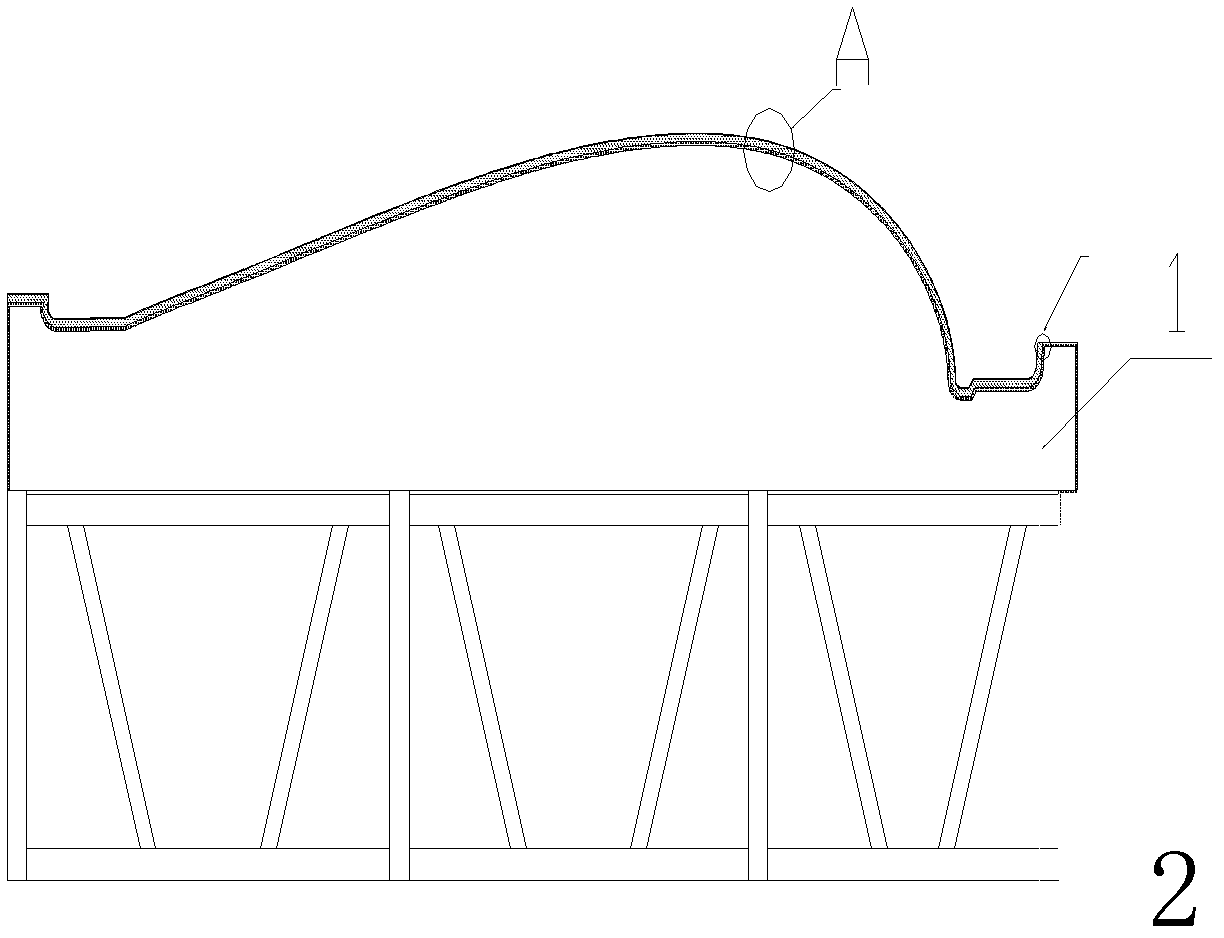

[0030] 1) Preparation of bottom metal steel frame:

[0031] The 3D shape of the blade designed by a professional design company is segmented in the computer. The principle of segmentation is that on the one hand, it can be convenient for road transportation by car, and the width does not exceed 4.5 meters. On the other hand, the length of each segment does not exceed 20 meters. The length of each section is basically close to the principle; currently the maximum length of CNC machine tool processing is 20 meters, and the horizontal projection of the designed 3D blade outline is made according to the horizontal projection drawing to make the bottom metal platform. The steel frame platform usually adopts the shape The square tube with a size of 60mm long x 60mm wide x 4mm wall thickness is processed by welding, and the height ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com