electric hammer

An electric hammer and support ring technology, applied in the direction of striking tools, lightweight impact tools, manufacturing tools, etc., can solve problems such as overheating deformation of the head shell, and achieve the effect of reducing impact force, high impact resistance, and speeding up the progress of work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

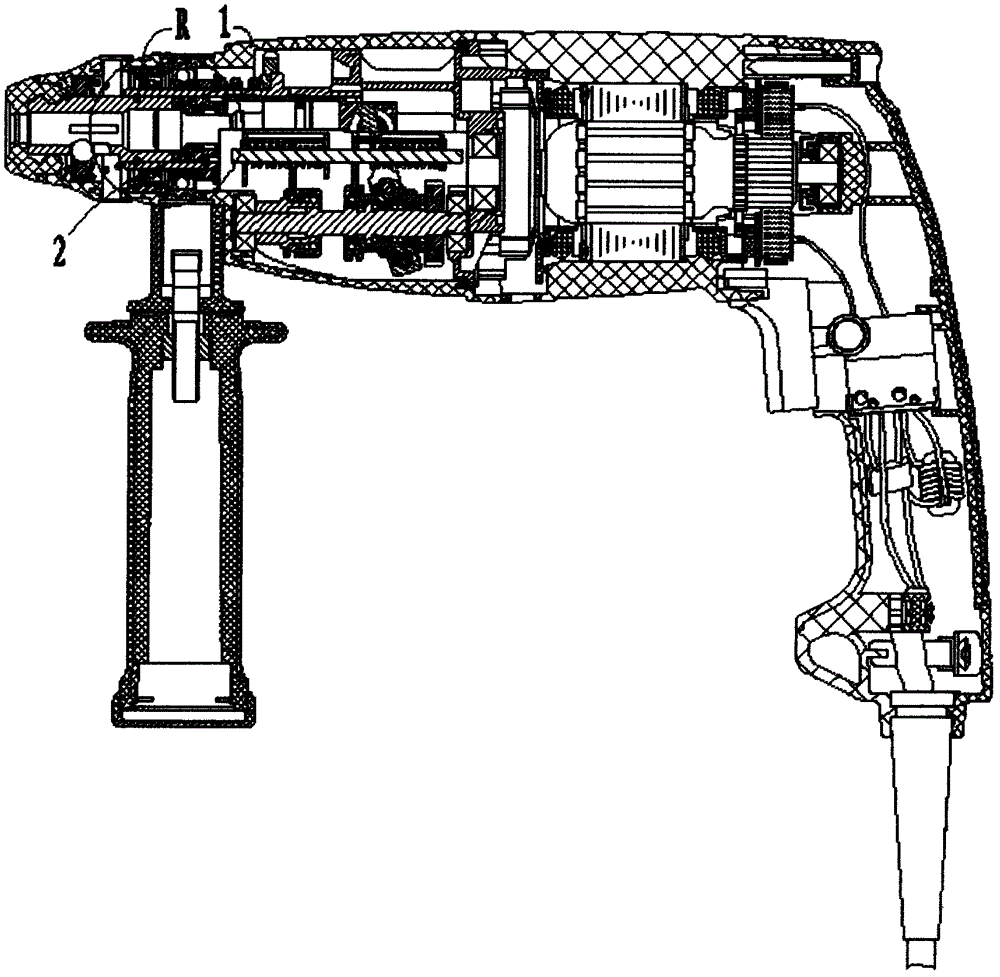

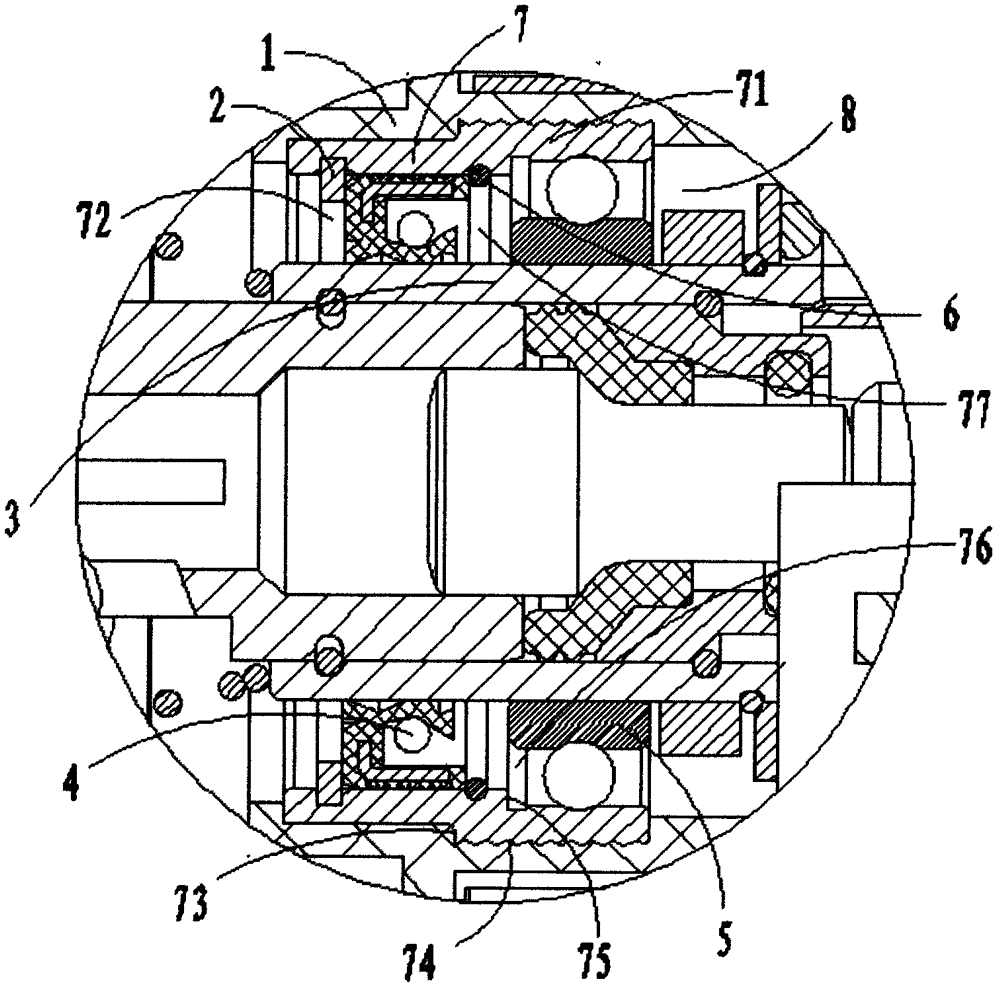

[0023] Embodiment 1: a kind of electric hammer such as figure 1 As shown, it includes a head shell 1 and a rotating sleeve 3, such as figure 2As shown, the head shell 1 is provided with a through hole 8, the rotary sleeve 3 is located in the through hole 8, the rotary sleeve 3 is rotatable relative to the head shell 1, and the deep groove ball bearings 5 are respectively provided between the head shell 1 and the rotary sleeve 3 and the seal ring 4, the seal ring 4 is located on one side of the deep groove ball bearing 5, the outer ring 71 of the bearing extends to the side of the seal ring 4 and forms a support ring 7, the width of the support ring 7 is greater than the width of the inner ring of the bearing, and the support ring 7 The diameter of the outer peripheral surface of one end on the same side as the sealing ring 4 is smaller than the diameter of the outer peripheral surface of the other end on the same side as the support ring 7 and the bearing to form an outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com