High torque starting method for high power alternating current (AC) servo driver

A servo drive, AC servo technology, applied in the field of servo drives, can solve the problems of weakening ripple torque, low-speed stability and control accuracy, and affecting the control accuracy of servo systems, so as to improve low-speed stability and weaken ripple torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

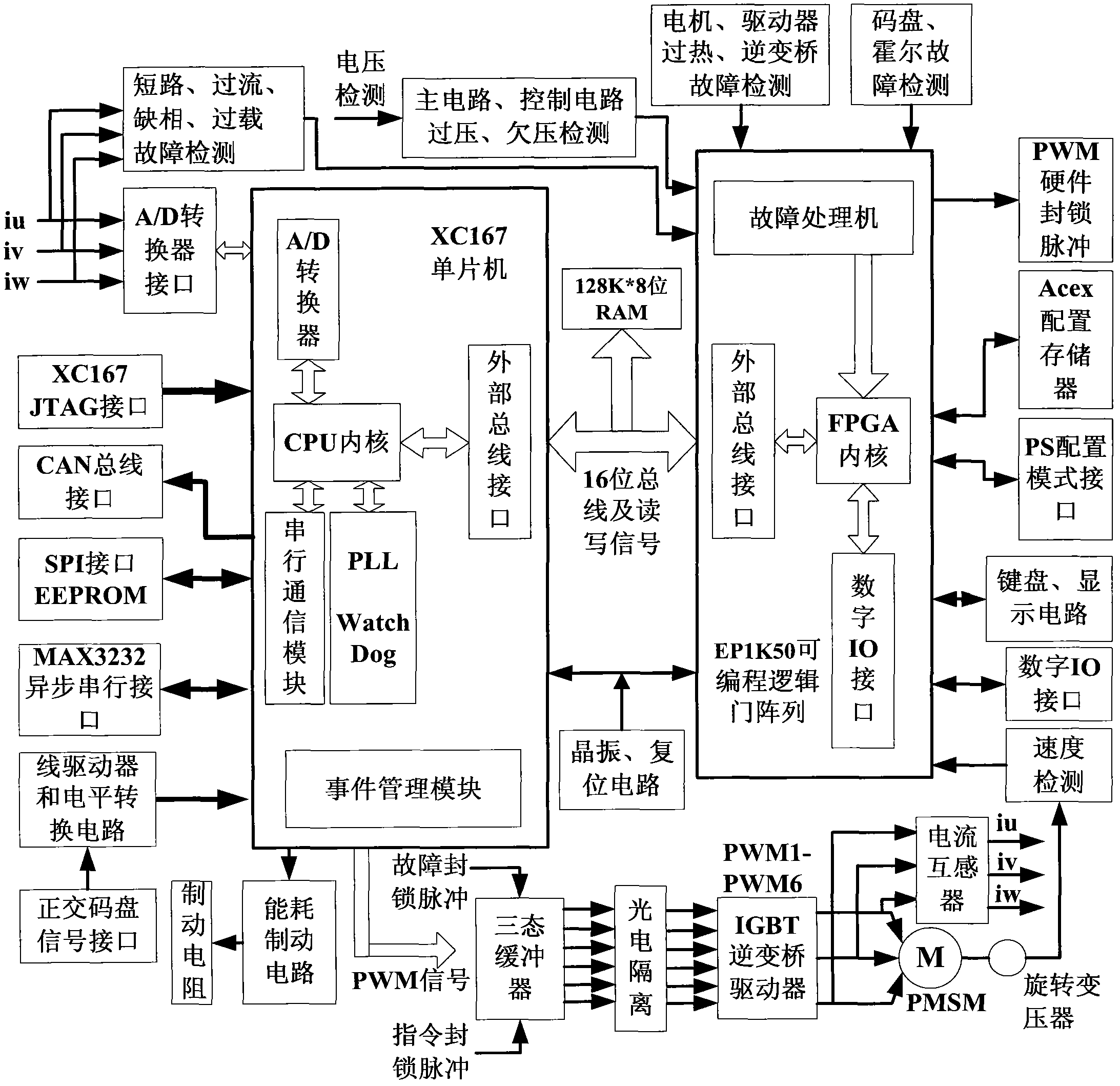

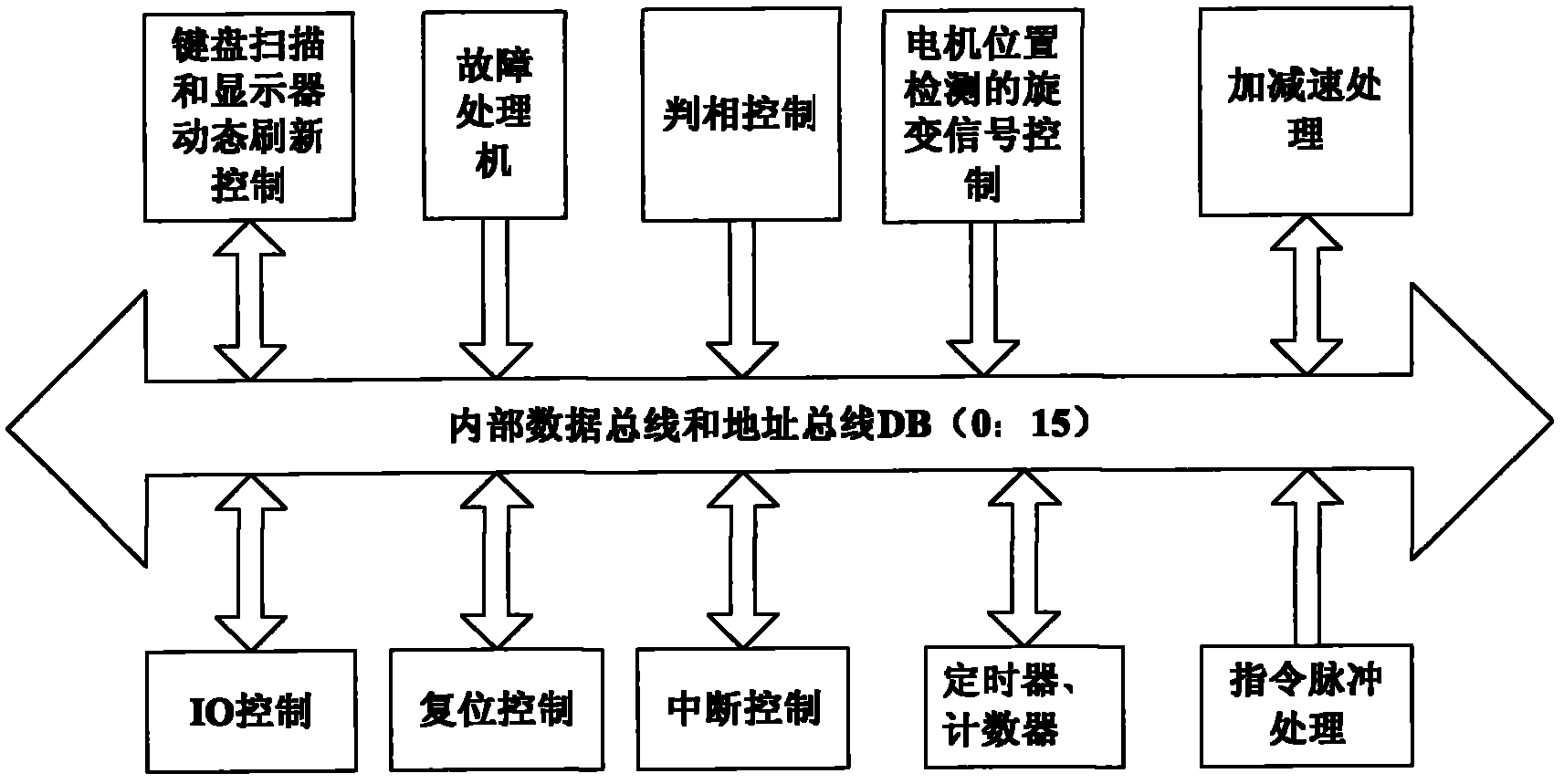

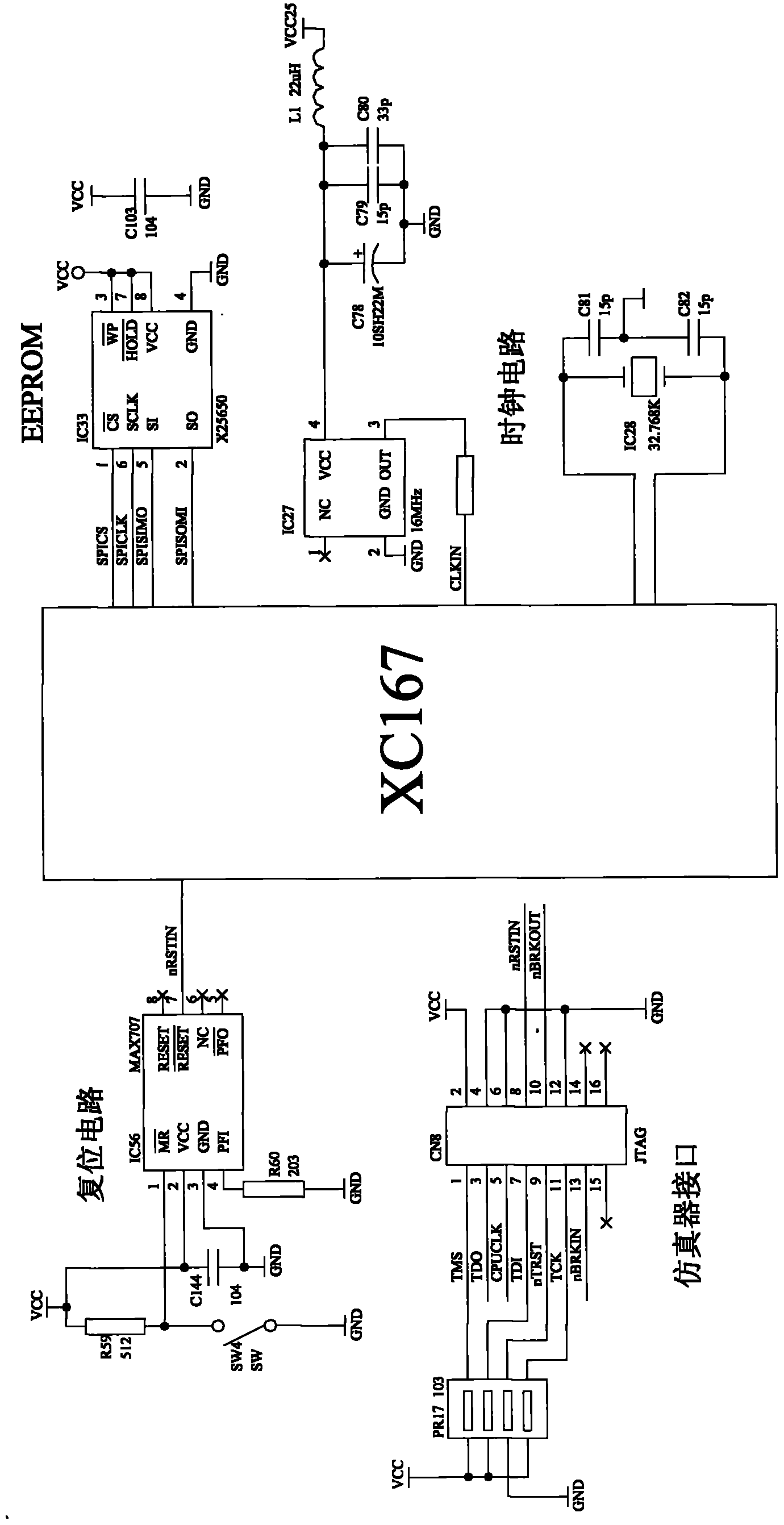

[0044] Below in conjunction with accompanying drawing, the present invention will be further described:

[0045]The control target of the servo driver is the permanent magnet synchronous servo motor (hereinafter referred to as the servo motor). The speed regulation function of the servo motor is mainly realized through the frequency conversion and variable voltage control technology, and the sinusoidal pulse width modulation (SPWM) technology is an effective method to realize the frequency conversion and variable voltage speed control. SPWM technology is divided into voltage (or current) SPWM from the perspective of the power supply and flux SPWM from the perspective of the motor. The latter is also called voltage space vector PWM (ie: SVPWM). Voltage

[0046] (or current) SPWM technology pursues to output a three-phase symmetrical sine wave with adjustable frequency and voltage. It has the advantages of simple model, good control linearity and easy implementation, but its b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com