Pillar steel

A technology of section steel and columns, which is applied in the processing and application of metal hollow section steel, can solve the problems that cannot meet the requirements of users' mechanical strength, rigidity and protection level, etc., and achieve the effect of light weight, guaranteed strength and effective installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

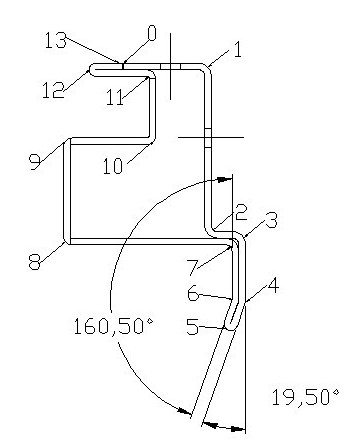

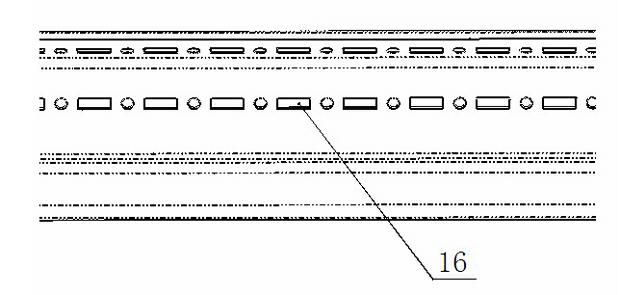

[0014] Such as Figure 1~2 A kind of upright section steel shown, comprises skeleton and the installation hole that has on the skeleton, and skeleton 17 is a cylinder, and the cross section of cylinder is a closed figure, and side one 14 and side two 15 of skeleton are respectively provided with installation hole 16, installs The holes are circular holes and rectangular holes, and are evenly distributed along the longitudinal direction of the skeleton. The closed figure of the cross-section of the cylinder is extended from the starting point 0 to the right, the first pleat 1 is folded 90 degrees downward, the second pleat 2 is folded 90 degrees to the right, the third pleat 3 is folded 90 degrees downward, and the pleat 3 is folded 19.5 degrees downward to the left The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com