Horizontal inductive tension detecting device for steel wire rope and horizontal inductive tension detecting method for same

A tension detection and wire rope technology, applied in the field of equipment detection and safety, can solve the problems of inconvenient installation, low measurement accuracy, poor real-time performance, etc., and achieve the effects of convenient installation and use, wide application range and low maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

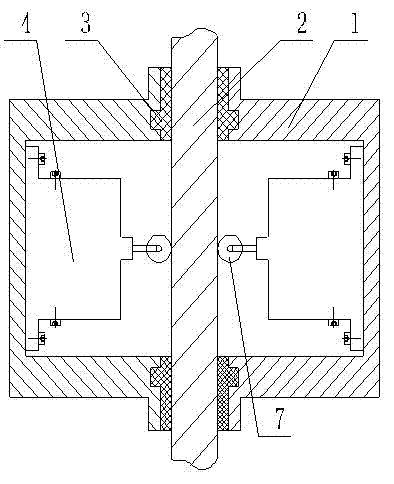

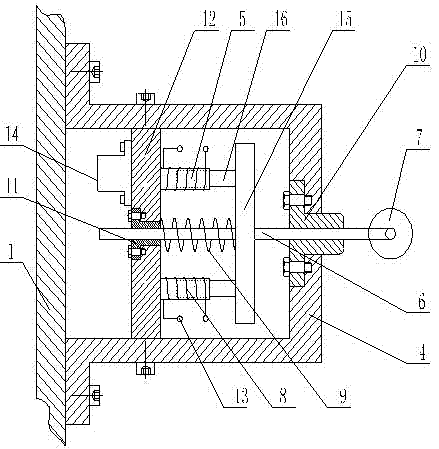

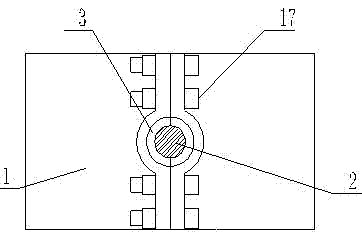

[0019] Shown in Fig. 1, 2, the horizontal inductance type wire rope tension detection device of the present invention mainly consists of housing 1, rubber pad 3, base 4, insulating sleeve 5, slide bar 6, roller 7, coil 8, spring 9, The base plate 12, the connection terminal 13, the signal processing unit 14, the slide plate 15, and the cylindrical magnetic core 16 are formed. The housing 1 is in two halves, which are fastened and fixed on the wire rope 2 symmetrically. The two halves of the housing 1 are arranged symmetrically and fastened on the wire rope 2 by bolts 17 and rubber pads 3, as shown in FIG. 3 . A rubber pad 3 is provided between the housing 1 and the fixed end of the steel wire rope 2; two bases 4 are symmetrically arranged in the housing 1, and a sliding rod 6 with the front protruding out of the body is respectively provided in the two base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com