Airflow gel spinning device

A gel and airflow technology, applied in textiles and papermaking, etc., can solve the problems of single yarn not being as tight as ply yarn, high cost of single yarn, low production efficiency, etc., to achieve hairiness sticking, cost-effective, and easy installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

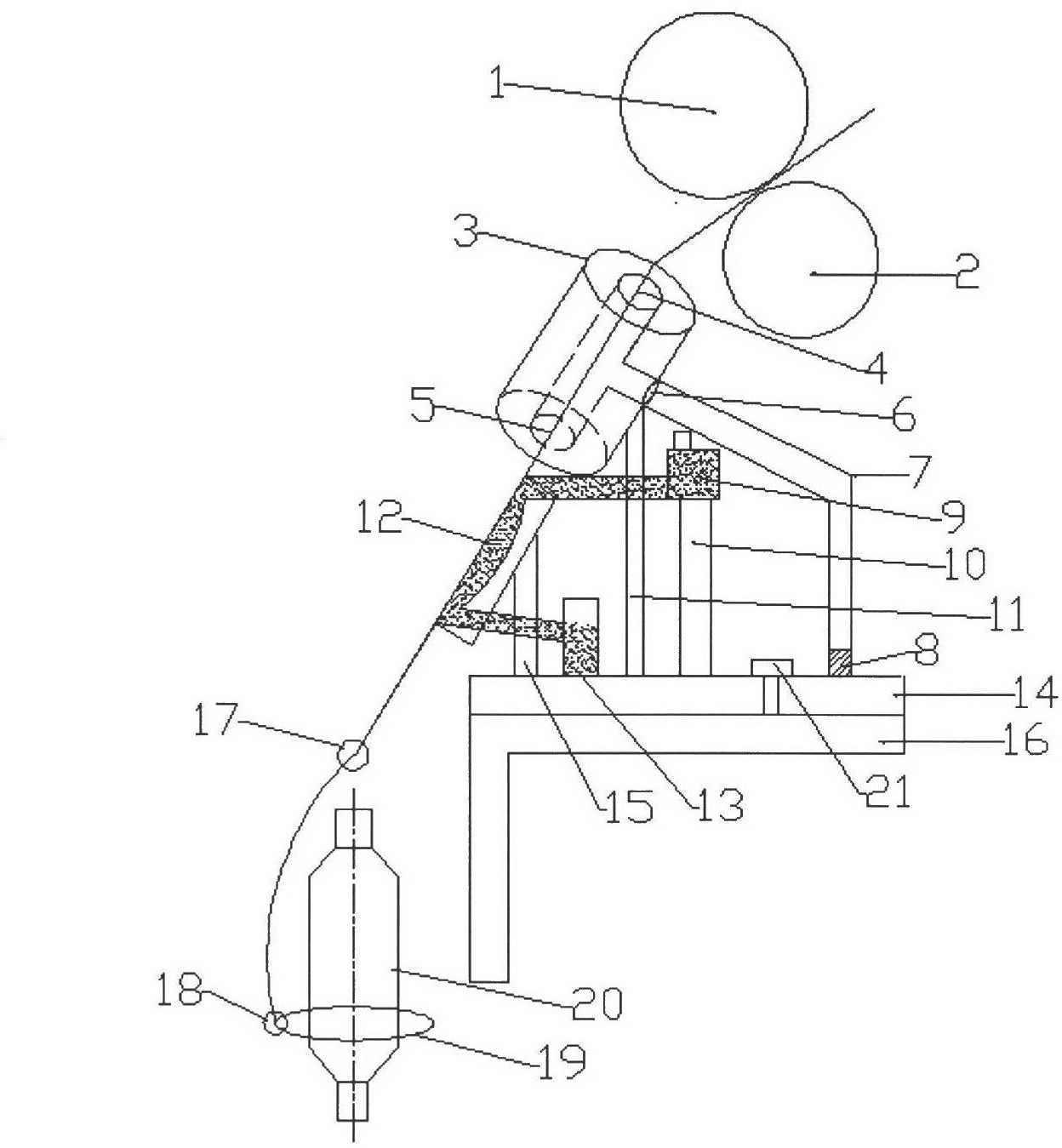

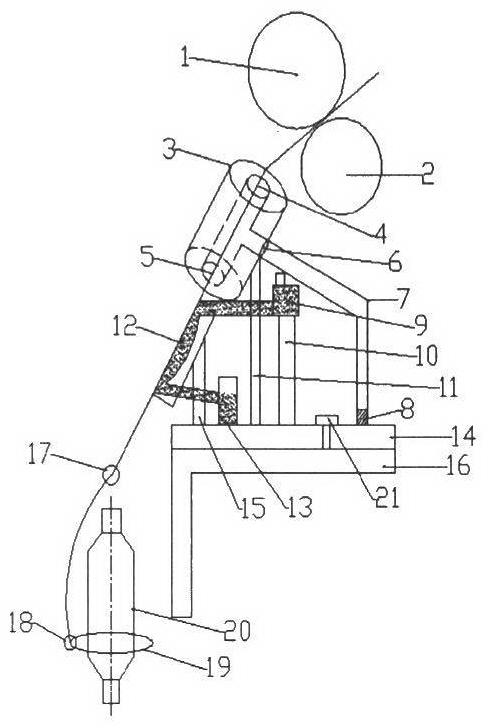

[0007] Depend on figure 1 As shown, after the fiber strands are held and output by the front roller (2) and the front rubber roller (1), they pass through the airflow device and the jelly lubrication device on the car table (16), and then the yarn reaches the yarn guide hook (17), and passes through the The rotation of the spindle drives the traveler (18) to rotate along the steel ring (19) track to twist the yarn and wind it on the bobbin (20). The airflow device is composed of yarn guiding porcelain eye (4), yarn guiding porcelain eye (5), air inlet (6), airflow conveying pipe (7), air valve switch (8) and airflow housing (3). The device is jointly supported by the bracket (11) and the bracket (14). The jelly lubricating device enters the jelly input port through the delivery pipe from the hydraulic pressure (9), and then enters the jelly tank (12), so that the yarn is stained with jelly, and the remaining jelly will flow to the jelly recovery bottle (13) for collection, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com