Preparation method of soybean episperm pectin gel polysaccharide

A gel-like, soybean technology, applied in the field of soybean seed coat deep processing, can solve the problems of low polysaccharide retention rate, residual activated carbon, complicated decolorization methods, etc., and achieves the effects of good fluidity, reduced dosage and good decolorization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

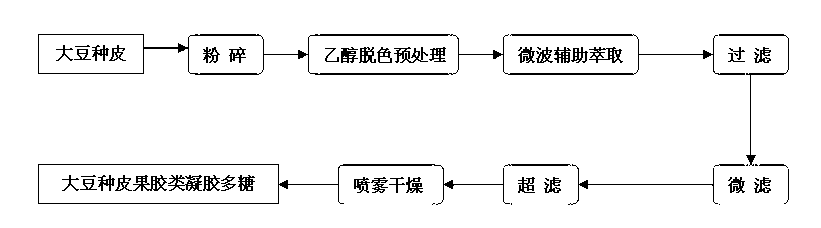

[0034] Such as figure 1 Shown, the method for preparing soybean seed coat pectin curdlan is as follows:

[0035] Use a universal pulverizer to pulverize the dried soybean seed coat removed by dry method, and collect the solid powder passed through a 40-mesh sieve; weigh 50 g of the crushed soybean seed coat powder, add 1 L of ethanol solution with a mass fraction of 0.5%, and stir at room temperature Treat for 30 minutes, then filter, recover ethanol, and dry the filter residue under reduced pressure; weigh 40 g of dried soybean seed coat powder after ethanol treatment, add 1 L of ammonium oxalate solution with a mass fraction of 0.2%, and perform microwave treatment. The microwave power is 200W, and the temperature is kept At 85°C, the microwave treatment time is 10 minutes; the filtrate is obtained by filtration, and the obtained filtrate is removed by microfiltration with a microporous membrane, and then concentrated to 20% of the original volume by ultrafiltration with a p...

Embodiment 2

[0037] Use a universal pulverizer to pulverize the dried soybean seed coats removed by wet method, and collect the solid powder passing through a 50-mesh sieve; weigh 67 g of the crushed soybean seed coat powder, add 1 L of ethanol solution with a mass fraction of 1%, and stir at room temperature Treat for 50 minutes, then filter, recover ethanol, and dry the filter residue under reduced pressure; weigh 50 g of dried soybean seed coat powder after ethanol treatment, add 1 L of ammonium oxalate solution with a mass fraction of 1.6%, and carry out microwave treatment. The microwave power is 300W, and the temperature is kept At 95°C, the microwave treatment time is 60min; the filtrate is filtered, and the obtained filtrate is removed by microfiltration with a microporous membrane, and then concentrated to 10% of the original volume by ultrafiltration with a polysulfone microporous ultrafiltration membrane. Membrane separation parameters: cross-flow velocity is 2cm / s, operating pre...

Embodiment 3

[0039]Use a universal pulverizer to pulverize the soybean seed coat, collect the solid powder passed through a 50-mesh sieve; weigh 50 g of the crushed soybean seed coat powder, add 1 L of ethanol solution with a mass fraction of 1.5%, stir at room temperature for 80 minutes, then filter and recover ethanol , the filter residue was dried under reduced pressure; weighed 67g of dried soybean seed coat powder after ethanol treatment, added 1L of ammonium oxalate solution with a mass fraction of 3%, and carried out microwave treatment. The microwave power was 350W, the temperature was kept at 98°C, and the microwave treatment time was 90min; the filtrate was filtered, and the resulting filtrate was removed by microfiltration with a microporous membrane, and then concentrated to 15% of the original volume by ultrafiltration with a polysulfone microporous ultrafiltration membrane. The membrane separation parameters for ultrafiltration concentration: cross-flow velocity of 6cm / s, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com