Rotary dye waste water decolorizing device and manufacturing method of adsorption plate

A dye wastewater, adsorption plate technology, applied in adsorption water/sewage treatment, textile industry wastewater treatment, flocculation/sedimentation water/sewage treatment, etc. The effect is thorough, easy to replace and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

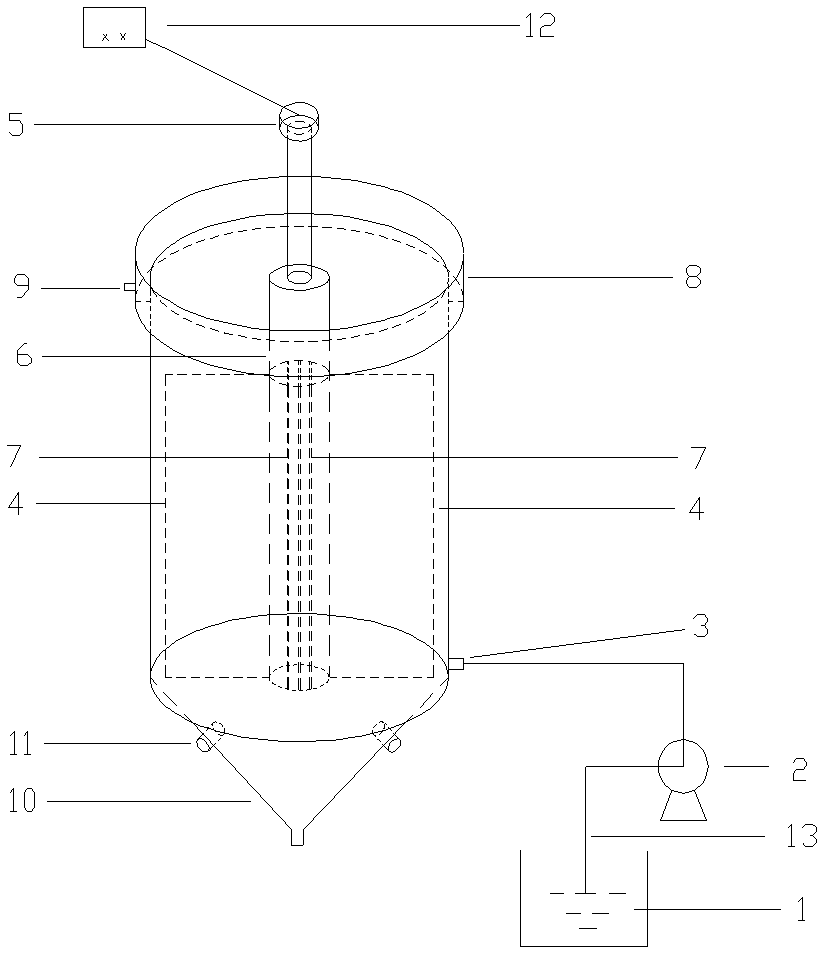

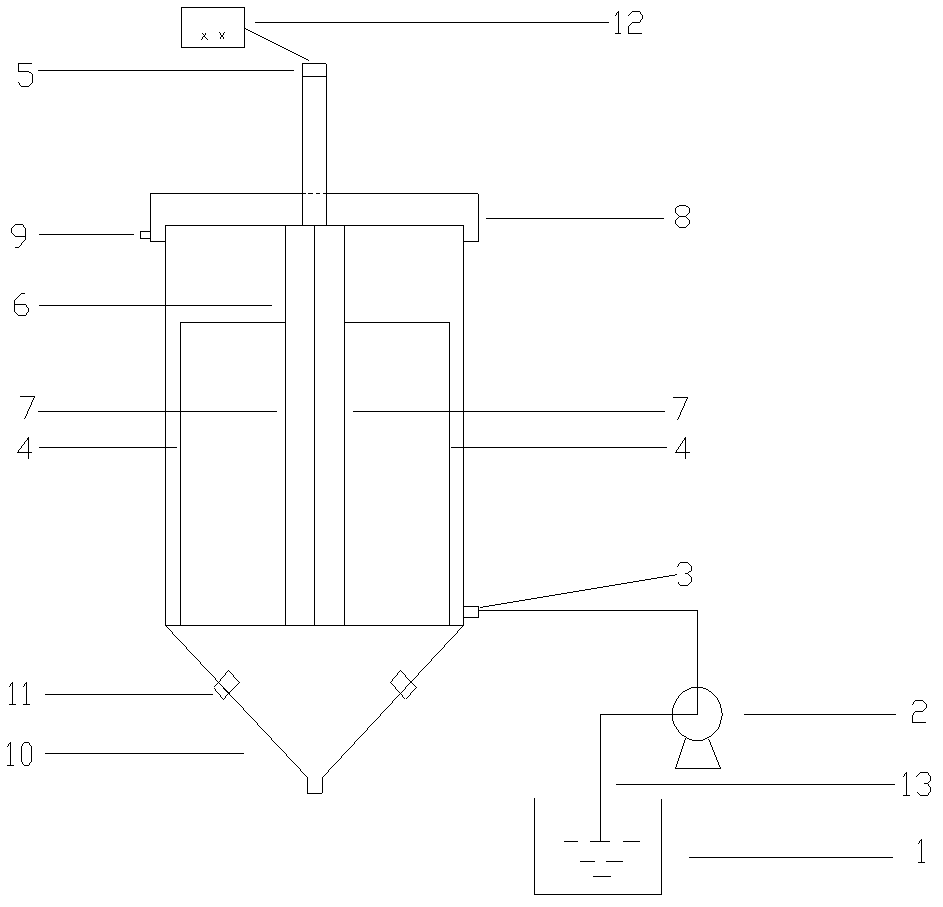

[0029] Embodiment 1: A rotary dye wastewater decolorization device, including a water inlet device, an adsorption plate reaction device, a rotating device, a sediment collection device, and a flushing device; wherein, the water inlet device is mainly composed of a sump 1 through a peristaltic pump 2 Connected to water inlet 3. The main body of the adsorption plate reaction device is a cylindrical reactor with an upper opening. In the reactor, eight adsorption plates 4 are fixed in the slots 7 on the rotating shaft, and the angle between two adjacent groups of adsorption plates 4 is is 45°; the bottom of the cylindrical reactor is an inverted conical sediment collection tank 10. An overflow weir 8 is provided on the upper part of the reactor, and a water outlet 9 is provided on the wall of the overflow weir 8 to connect the outlet water collecting device.

[0030] The rotating device is mainly composed of a drive bearing 5 and a rotating shaft 6; the rotating shaft 6 is locate...

Embodiment 2

[0037] Embodiment 2: Rotary dye wastewater decolorization device, as described in Embodiment 1, the difference is that the weight ratio of red mud and sludge on the adsorption plate is 78:12. The adsorption plate has a decolorization rate of more than 95% for dye wastewater containing acid scarlet.

Embodiment 3

[0038] Embodiment 3: Rotary dye wastewater decolorization device, as described in Embodiment 1, the difference is 80 parts of red mud, 8 parts of sludge, 2 parts of sodium hydroxymethyl cellulose, and 10 parts of water on the adsorption plate. The adsorption plate has a decolorization rate of more than 99% for dye wastewater containing disperse brilliant blue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com