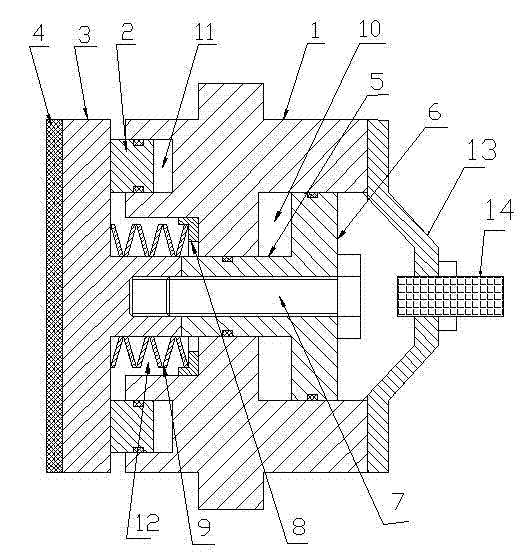

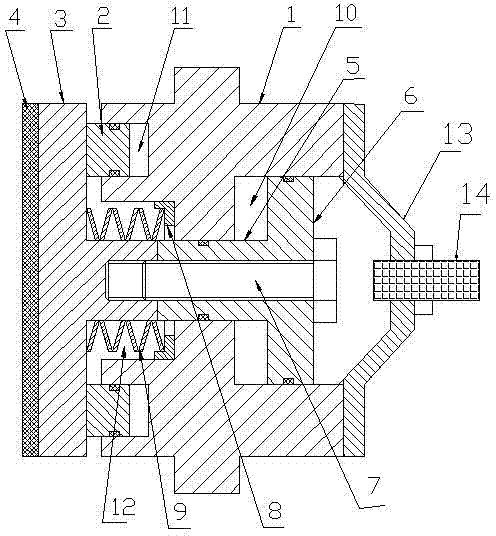

Disc brake structure

A disc brake and brake body technology, applied in the direction of brake type, hoisting device, mechanical equipment, etc., can solve the problems of easy fatigue, brake failure, poor intelligence, etc., and achieve improved intelligence effect, uniform braking force, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The relief cylinder 10 and the spring chamber 11 are arranged at both ends of the cylinder body 1 respectively, there is a through hole communicating between the relief cylinder 10 and the spring chamber 11, and the brake cylinder 11 is arranged on the end face of the cylinder body 1 at the same end as the spring chamber 12. The section of the moving cylinder 11 is in the shape of a ring, the piston 6 is installed in the relief cylinder 10, the guide rod 5 passes through the middle hole of the spring chamber 12 and the relief cylinder 10, and one end of the guide rod 5 is connected and fixed with the piston 6, The fastening bolt 7 passes through the piston 6 and the guide rod 5 in turn and is connected and fixed with the brake body 3. A spring seat 8 is installed in the spring chamber 12, and a butterfly spring 9 is installed on the spring seat 8. The butterfly spring 9 is used for the brake. The body 3 forms a compressed state, and an annular piston 2 is installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com