Internal expanding pile hanging device

An internal expansion and pile hanging technology, applied in the direction of load hanging components, transportation and packaging, can solve problems such as expensive, and achieve the effect of increasing bearing capacity, simplifying the operation process, and evenly distributing the expansion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

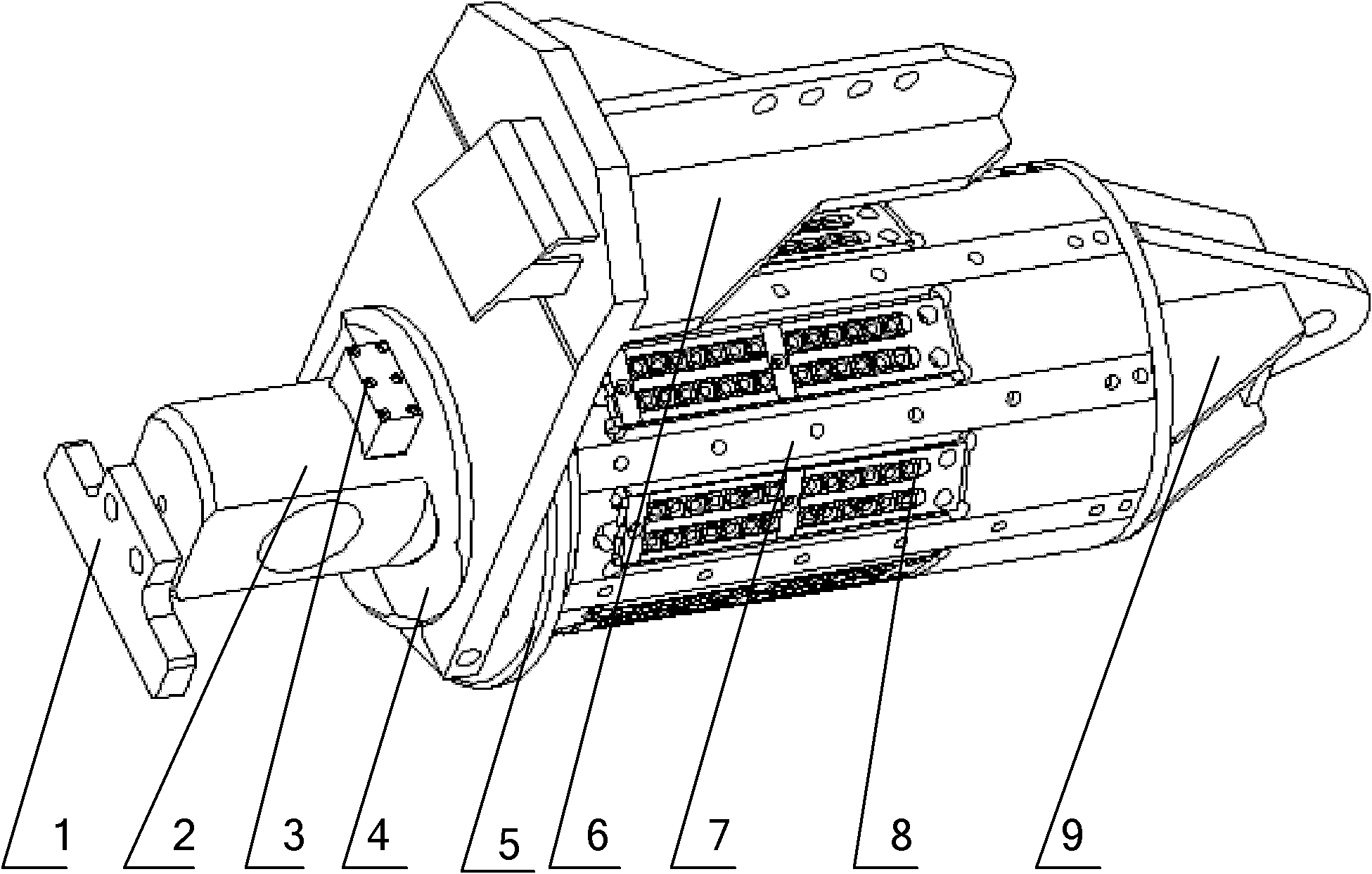

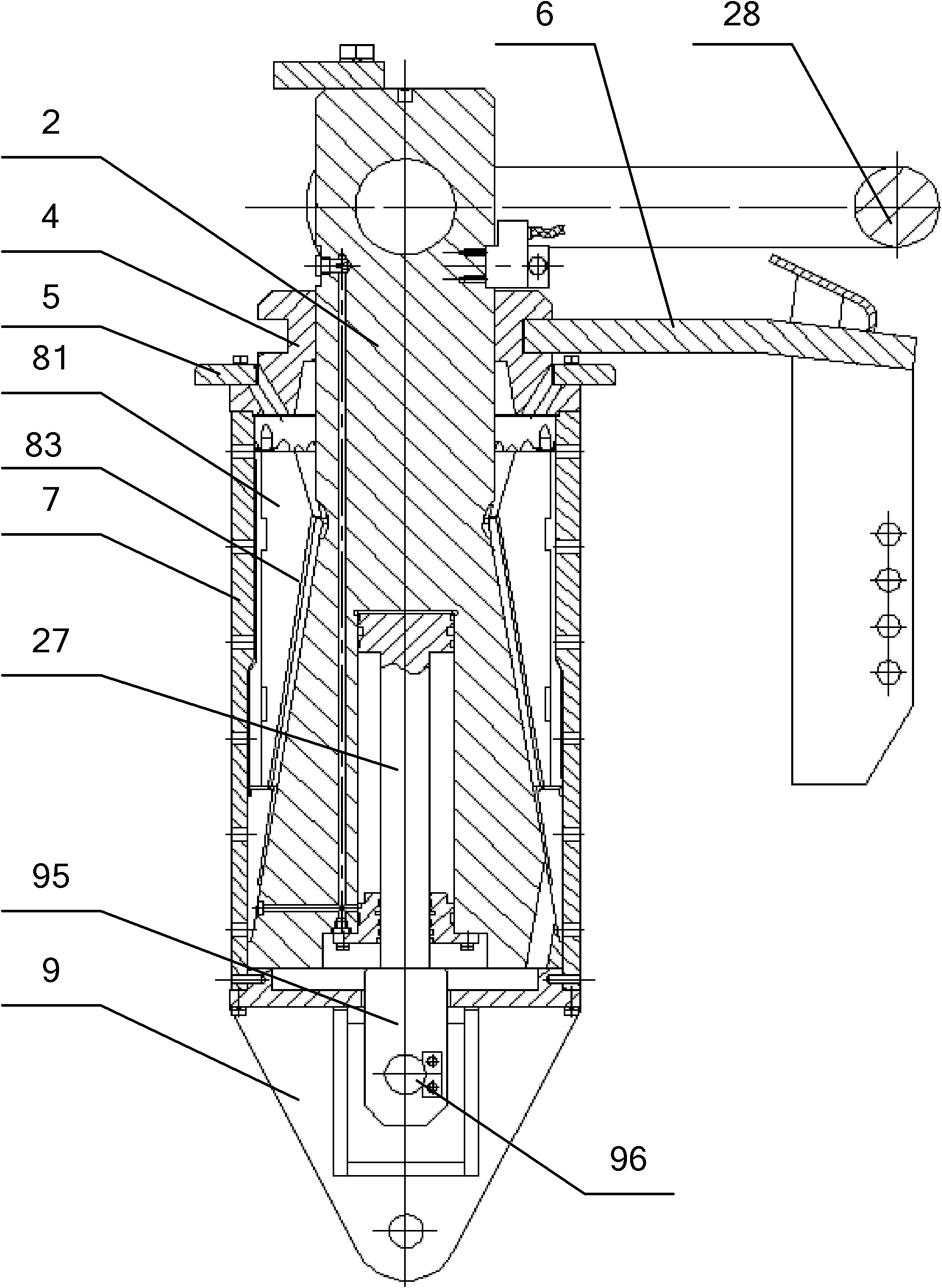

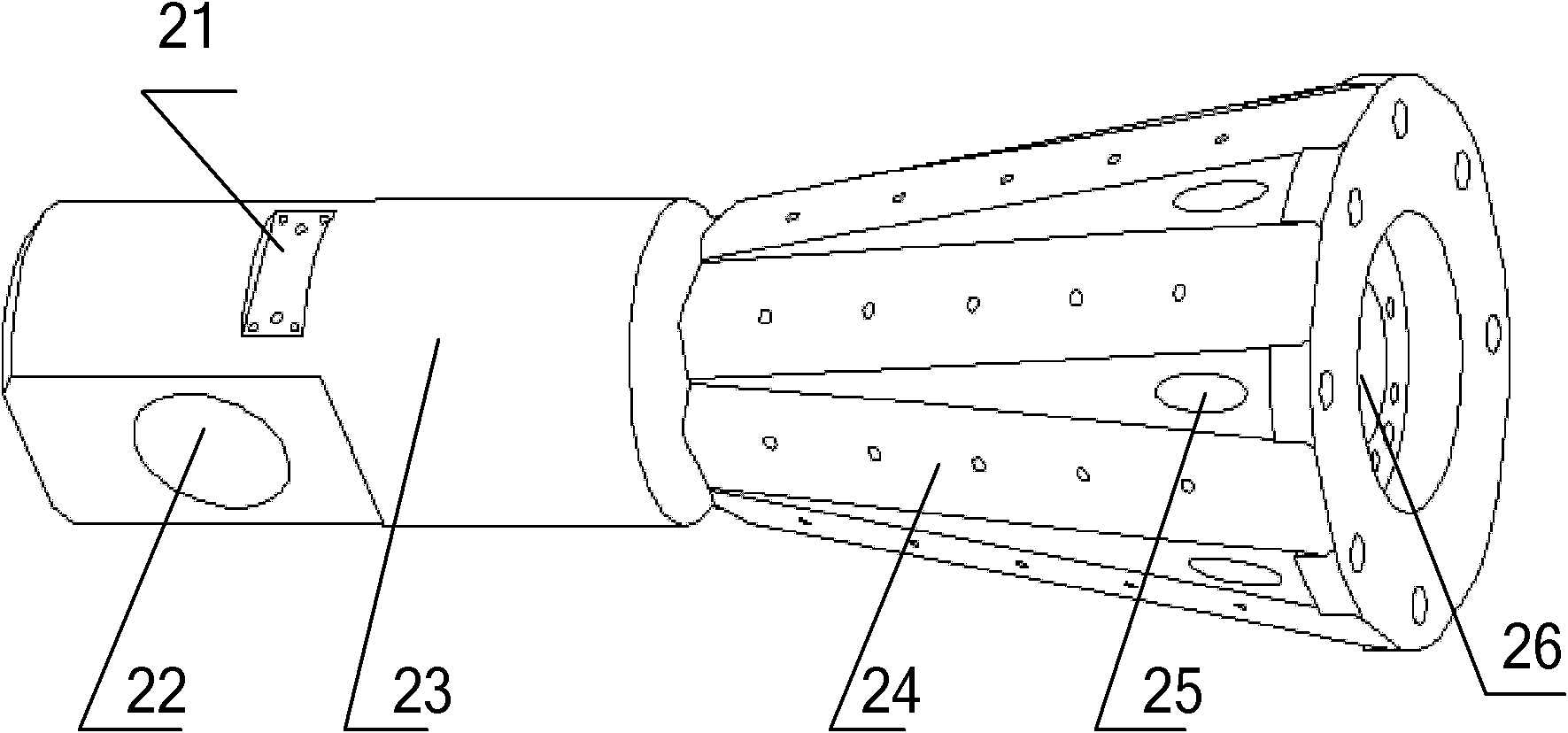

[0039] Such as Figure 1-Figure 8 As shown, the present invention is provided with driving cone 2, cylinder 7, cylinder head 4, guide cone 9, balance boom 6 and external expansion block 8; wherein, the two ends of cylinder 7 are respectively connected with cylinder head 4 and The guide cone 9 is fixedly connected to form a closed cavity; and the inner diameter of the cylinder head 4 cooperates with the upper cylindrical part of the driving cone 2 to realize the axial movement of the driving cone 2 in the closed cavity; at the same time, A balance boom 6 is installed on the barrel head 4, and the driving cone 2 cooperates with several windows provided on the cylindrical barrel 7 through several external expansion blocks 8. In this embodiment: the cylindrical barrel 7 and the barrel head 4 are connected as a whole by bolts, and the guide cone 9 and the cylindrical barrel 7 are connected as a whole by bolts at the other end, so that the three of them constitute a cavity for exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com