Cushion-plate-free loader for bamboo flakeboard

A particle board and board loading machine technology, which is applied in applications, household components, household appliances, etc., can solve the problems of high failure rate and inconvenient maintenance, and achieve the effect of reliable work, fast board loading and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

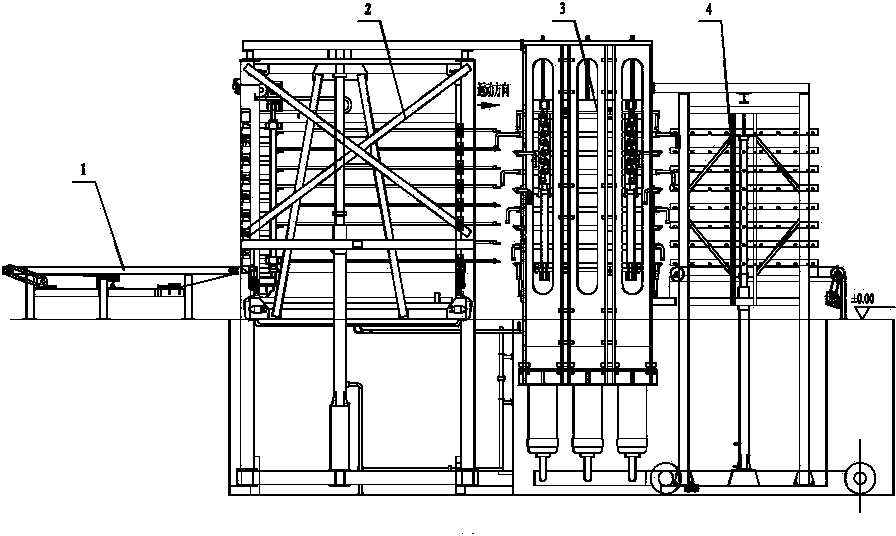

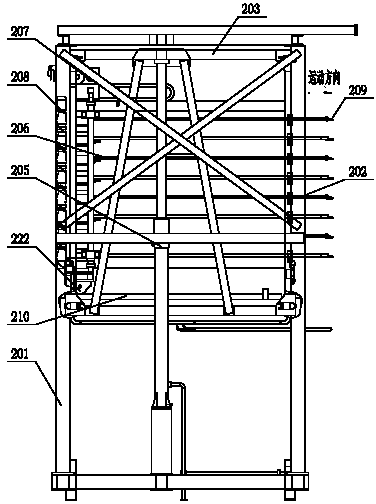

[0031] Such as figure 2, the device mainly includes the main frame 201, the hanging cage 203 in the main frame, the trolley loader (206) installed in the hanging cage 203, and the hanging cage 203 is fixedly connected with the upper end of the oil cylinder 205, and the lower end of the oil cylinder 205 Fixed on the main frame 201; The oil cylinder 205 drives the cage 03 to go up and down, and accepts the slabs from the belt conveyor 1 . And in hanging cage 203, dolly frame 215 and track 210 are set, and walking wheel 222 is installed at the bottom of dolly frame 215, and the track 210 that is set in the walking wheel 222 of dolly frame 215 and hanging cage 203 is mobile pair connection.

[0032] In the trolley frame 215, 8 trolley loading machines 206 (such as figure 2 , 3 ). Every dolly loading machine 206 rotates and transports a slab (such as Figure 6 ). The trolley loading machine 206 includes a model K47A-19.6-Y-1.5-B62 motor 208 and a belt 202 with a reducer, th...

Embodiment 2

[0035] On both sides of the cage 203, racks 219 are fixed symmetrically along the horizontal movement direction of the trolley frame 215, and a gear 218 corresponding to the rack 219 is fixedly installed on the trolley frame 215. The rack 219 and the gear 218 form a rack and pinion Secondary connections (such as figure 2 , 3 ). All the other are identical with embodiment 1.

Embodiment 3

[0037] Such as Figure 5 , the locking device 204 of the cage 203 includes an oil cylinder 220, a connecting rod 221 and a support block 223, wherein the oil cylinder 220 and the connecting rod 221 are fixed on the main frame 201, the lower end of the connecting rod 221 is hingedly connected with the oil cylinder 220, and the fulcrum is connected with the main frame The frame 201 is hinged, and two support blocks 223 are symmetrically welded on both sides of the cage 203. The upper end of the connecting rod 221 extends below the support block 223 through the movement of the oil cylinder 220 to support the cage 203, and locks the cage 203 when it stops. Tight, return when hanging cage 203 lifts, plays safety protection effect. The model of the above oil cylinder is HSGL01-50 / 25E-1111. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com