Method for manufacturing connecting rod type plunger

A manufacturing method and connecting rod-type technology, applied in the field of aviation machinery, can solve the problems of difficulty in refinishing components, and achieve the effects of ensuring normal oil supply, good closing quality and large pull-off force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

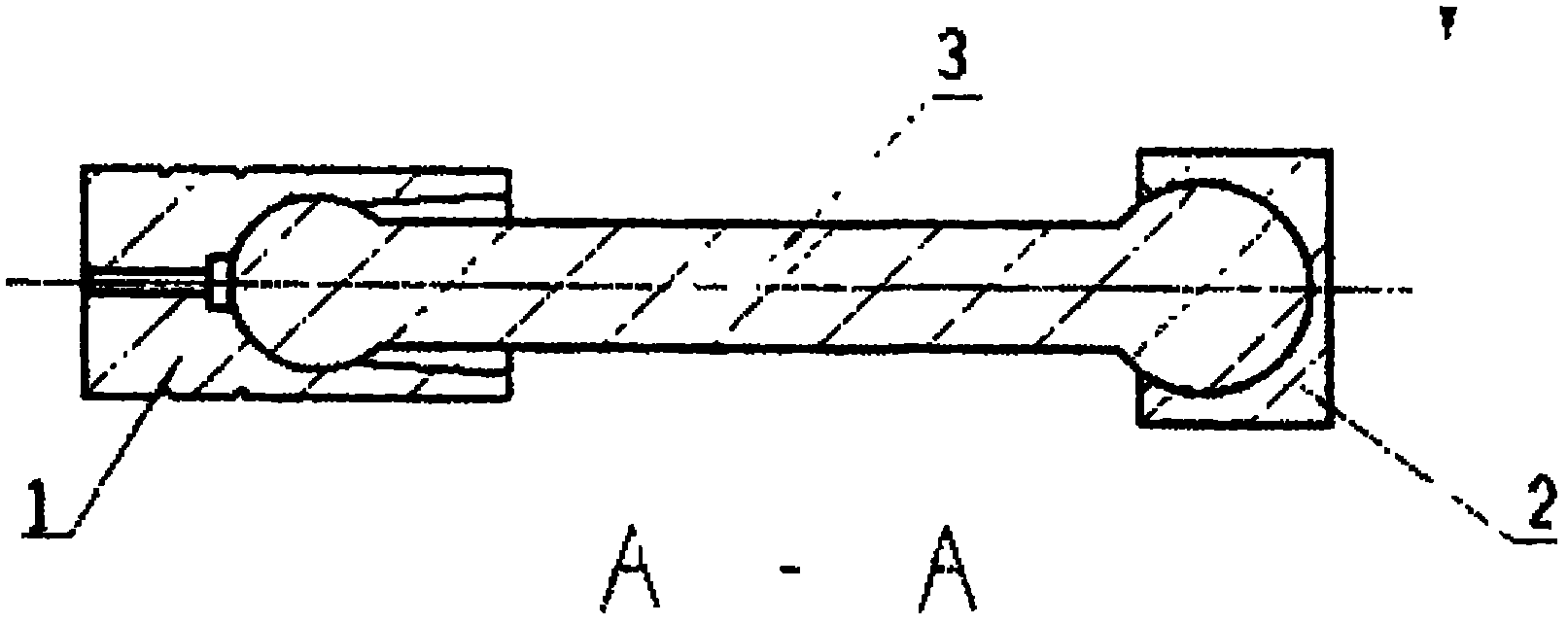

[0026] Below in conjunction with accompanying drawing the present invention is described in further detail, please refer to Figure 1 to Figure 9 .

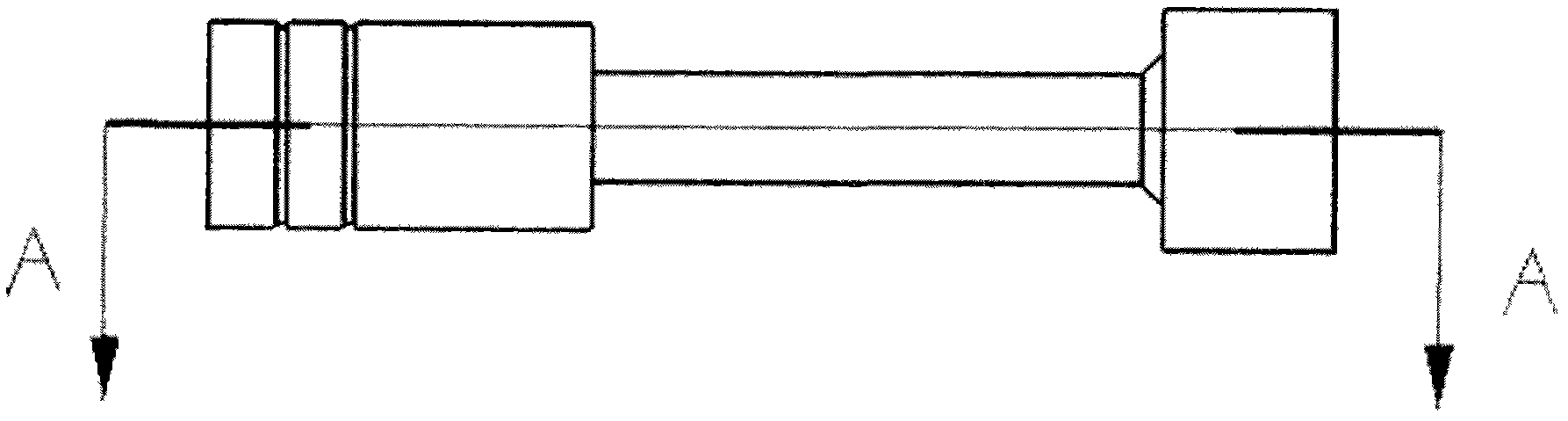

[0027] Such as figure 1 and figure 2 As shown, a method for manufacturing a connecting rod plunger, the connecting rod plunger includes a piston 1, a socket 2 and a piston rod 3, and a tapered opening bush 4, a base assembly 5 and a pressure head 6 are used to close the mouth, including The following steps:

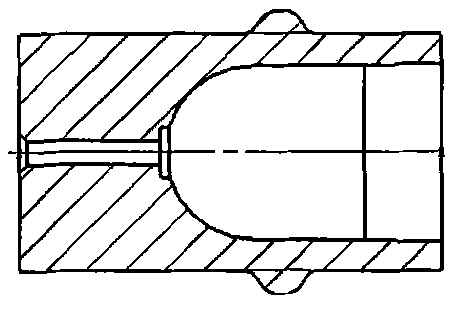

[0028] Such as image 3 and Figure 4 As shown, Step 1: Make a protrusion at the corresponding position between the outer surface of piston 1 and socket 2 and the center of the inner spherical surface;

[0029] Such as Figure 5 As shown, if the outer diameter of the piston is smaller than the outer diameter of the socket, close the piston first. Step 2: Close the end of the piston 1: put the piston rod 3 into the inner spherical surface of the piston 1, so that the inner spherical surface of the piston 1 is in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com