Temperature swing adsorption gas purification device

A gas purification device and temperature swing adsorption technology, applied in the field of temperature swing adsorption, can solve the problems of large consumption of regeneration gas and high device operating costs, and achieve the effects of saving energy, reducing equipment costs and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

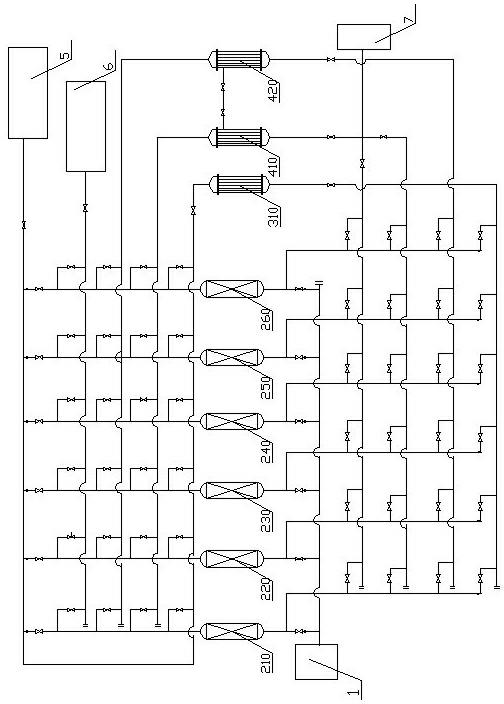

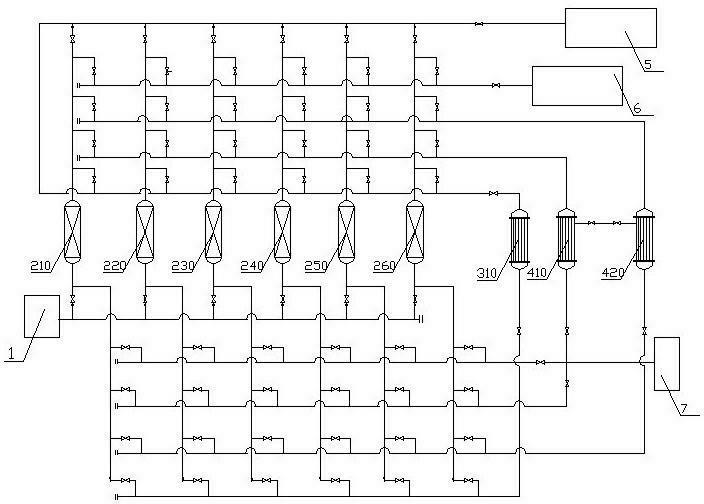

[0031] As shown in the figure, the temperature swing adsorption gas purification device includes a feed port 1, a first adsorber 210, a second adsorber 220, a third adsorber 230, a fourth adsorber 240, a fifth adsorber 250, and a sixth adsorber 260 , the first cooler 310 , the first heater 410 , the second heater 420 , the discharge port 5 , the regenerative gas input device 6 , and the venting device 7 . The first adsorber 210, the second adsorber 220, the third adsorber 230, the fourth adsorber 240, the fifth adsorber 250, the sixth adsorber 260, the first cooler 310, the first heater 410, the second The heaters 420 are connected through pipelines, and the feed port 1, the discharge port 5, the regeneration gas input device 6, and the vent device 7 are respectively connected with the adsorber through pipes. Valves are respectively arranged on each pipeline, and the valves are cut-off valves, program-controlled valves or regulating valves.

[0032] The raw material gas in th...

Embodiment 2

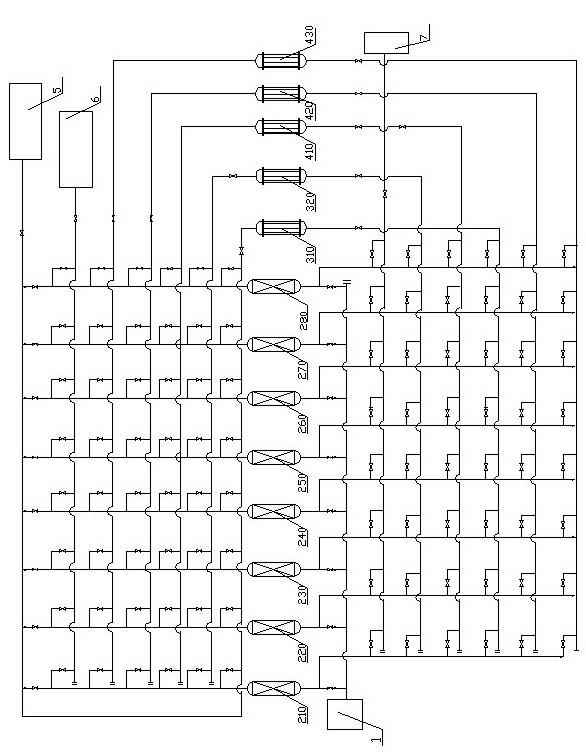

[0036] As shown in the figure, the temperature swing adsorption gas purification device includes a feed port 1, a first adsorber 210, a second adsorber 220, a third adsorber 230, a fourth adsorber 240, a fifth adsorber 250, and a sixth adsorber 260, seventh adsorber 270, eighth adsorber 280, first cooler 310, second cooler 320, first heater 410, second heater 420, third heater 430, outlet 5, regeneration Gas input device 6, venting device 7. The first adsorber 210, the second adsorber 220, the third adsorber 230, the fourth adsorber 240, the fifth adsorber 250, the sixth adsorber 260, the seventh adsorber 270, the eighth adsorber 280, the first adsorber The cooler 310, the second cooler 320, the first heater 410, the second heater 420, and the third heater 430 are connected through pipelines, the feed port 1, the discharge port 5, the regenerative gas input device 6, the vent The devices 7 are respectively connected to the adsorbers through pipelines. Valves are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com